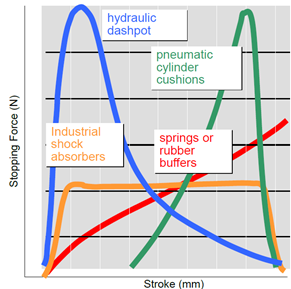

Different techniques for cushioning impacts and shocks absorb energy in different ways, both in terms of amount and damping characteristics. The gentlest is a smooth energy absorption, as shown by the orange curve in the diagram. This is beneficial for machine longevity, production speed, and the working environment, for example by reducing noise levels. Below, we compare and describe how different types of shock absorbers perform when absorbing an impact.

What are the characteristic properties of the different shock absorbers?

These absorb most of the energy at the start of the stroke since damping occurs through a fixed orifice. This results in a high reaction force at impact but little energy absorption during the remainder of the stroke.

This type absorbs most energy at the end of the stroke, as air compression occurs later in the stroke. This leads to a large reaction force at the end.

These absorb energy with a linear increase in force due to energy stored in the spring. A major disadvantage is the creation of multiple rebounds and repeated impacts.

A properly sized hydraulic industrial shock absorber absorbs energy evenly throughout the stroke by using multiple orifices of varying diameter. This avoids force spikes and provides a very smooth damping curve. It is optimal for absorbing kinetic energy and can reduce component stress by up to 60% compared to other shock absorbers.

Feel free to contact us or ACE Controls for assistance in selecting the right shock absorber.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se