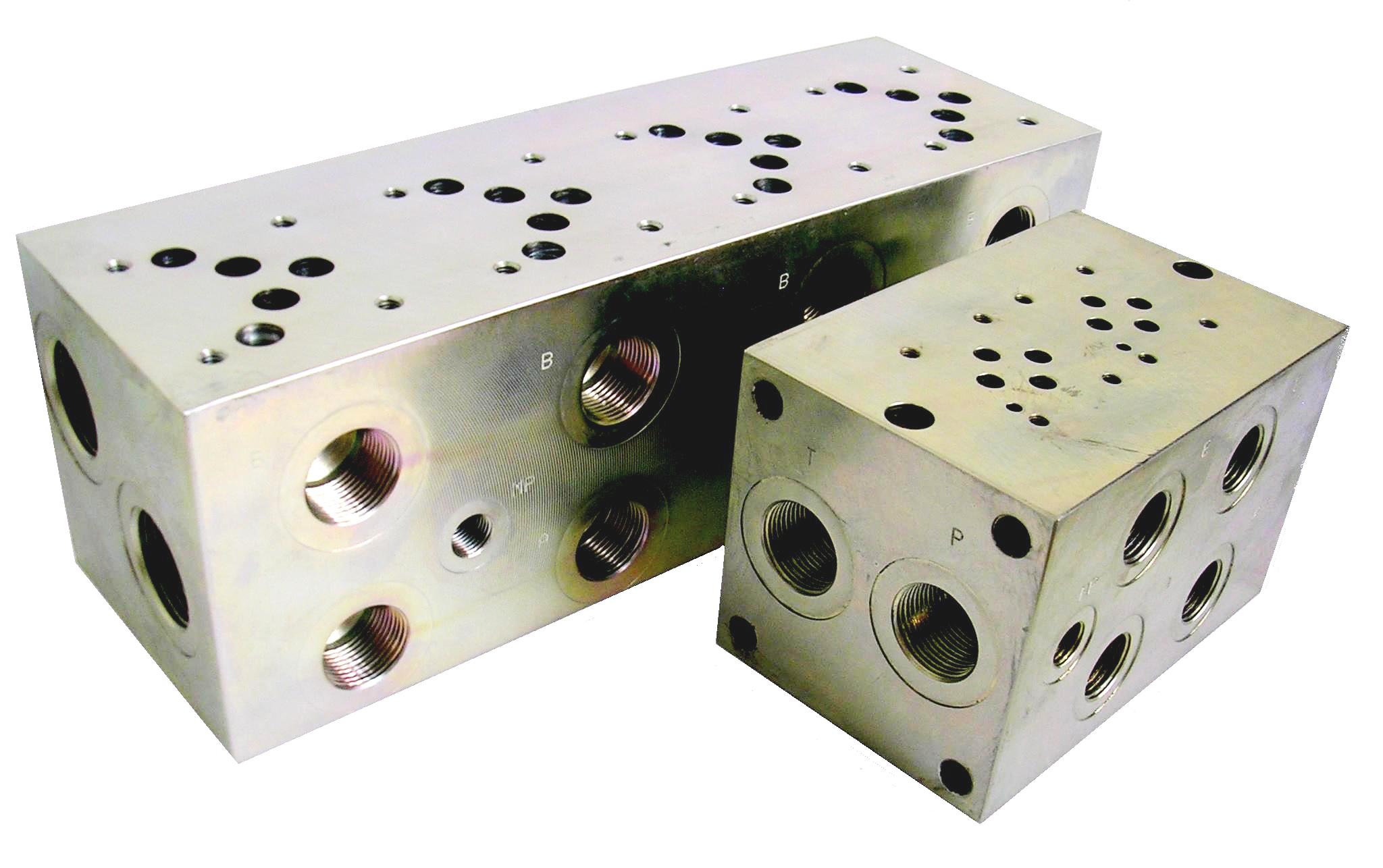

Be meticulous when assembling sandwich stacks – improper installation can lead to leakage, which affects both performance and operational reliability.

When stacking multiple sandwich manifolds on top of each other, it is especially important that each contact surface between manifolds is properly sealed and accurately aligned. Even minor assembly errors can quickly accumulate and cause system malfunctions.

Below are some key tips to keep in mind when assembling sandwich manifold bodies stacks:

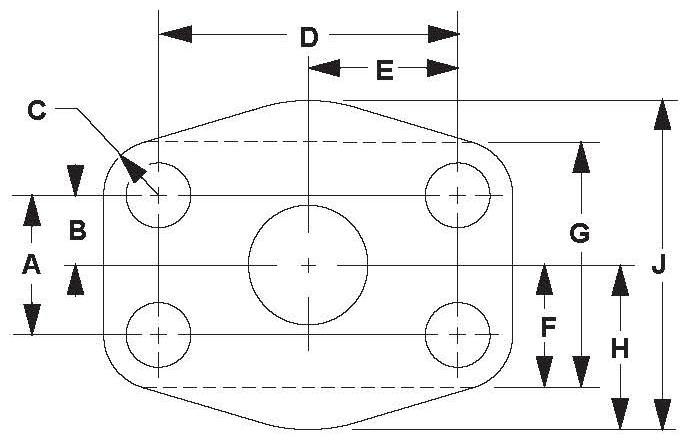

Ensure that all sealing surfaces are undamaged and free from any manufacturing residue.

Do not polish the surfaces – the machining marks left during manufacturing are beneficial, as they help prevent the O-rings from acting like pumps.

Inspect the O-ring plates to make sure they are not damaged.

Threaded rods and bolts must not bottom out in the manifold holes.

It is critical to keep the O-ring sealing surfaces dry during assembly. If oil is trapped underneath the O-rings, they may develop hydrostatic properties and create fluid paths from the pressurized ports to the outside of the stack. (As described in the first point, the O-rings can then act as a “pump”.)

Download a description on how to install sandwich stacks here.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se