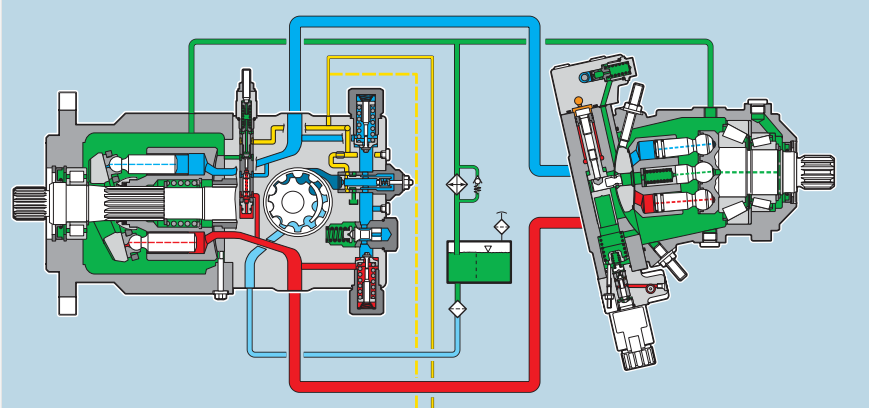

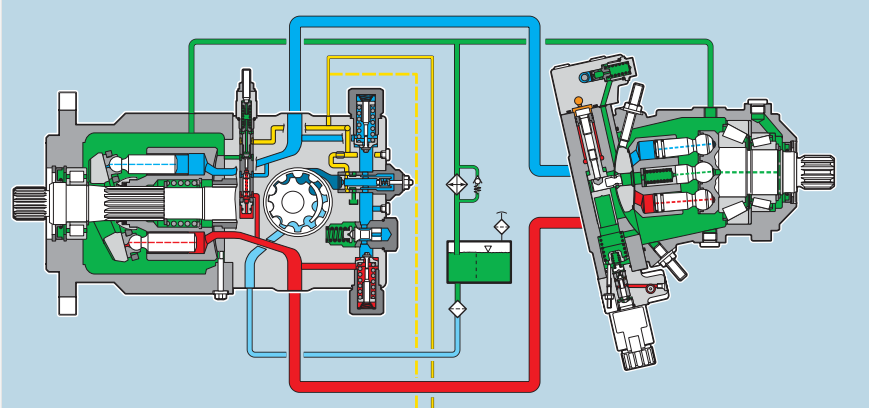

A hydrostatic transmission is a type of power transmission system that uses hydraulics to transfer power and regulate speed in a machine or vehicle. It consists of three main components: a hydraulic motor, a hydraulic pump, and a control system.

Hydraulic Pump:

A hydraulic pump is powered by a prime mover, such as an internal combustion engine or an electric motor. The pump draws in hydraulic fluid and pressurizes it to a high level. This pressure generates the power that is transmitted to the hydraulic motor.

We commonly use the Bosch Rexroth hydrostatic pump A4VG, which is an axial piston pump.

Hydraulic Motor:

A hydraulic motor receives the high-pressure hydraulic fluid from the pump and converts the hydraulic energy into mechanical power and rotation. The hydraulic motor is connected to the driven wheels, components, or moving parts of the machine or vehicle. By adjusting the speed and direction of the incoming hydraulic fluid, the hydraulic motor can be controlled, thereby changing the machine’s speed and direction.

We frequently use the Bosch Rexroth hydraulic motor A6VM, which is an axial piston motor.

Control System:

The control system regulates the flow of hydraulic fluid between the pump and the motor to adjust the speed and direction of the machine or vehicle. It can include various components such as valves, regulators, and control signals from the operator’s controls or computerized control systems.

The advantages of hydrostatic transmissions include smooth acceleration, fast response, independent control of speed and direction, and the ability to transfer high torque. They are used in many applications that require precise control of speed and movement, including tractors, excavators, forestry machines, construction equipment, and vehicles such as lawn mowers and snow plows.

It’s important to note that a hydrostatic transmission differs from a mechanical transmission, where power is transferred through mechanical linkages and gears. In a hydrostatic transmission, power is transferred via hydraulic pressure and flow instead of mechanical components.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se