Sun Hydraulics offers over 180 different counterbalance valves for the mobile, industrial, and marine markets. With so many options, it can be challenging to know which one is right for your specific application.

Below is an overview guide of the valve families offered by Sun Hydraulics. For further assistance and guidance in choosing the right valve for your system, please contact one of our sales engineers.

Valves from the standard family fit most applications. They are internally drained, available with several different pilot ratios, and feature a check valve set at either 1.7 or 0.3 bar. Fixed settings can be chosen for series 1 and 2. Valves should be set at 1.3 times the maximum load.

Tips:

Note that any backpressure on port 2 adds to the set pressure. If backpressure is an issue, choose a valve from the Drained Counterbalance Valve series.

Do not select an oversized valve, as this can create instability in the system. Variants with lower flow capacity but the same cavity are available.

These counterbalance valves offer an average 30% energy savings compared to conventional counterbalance valves while maintaining stability—a challenge with traditional designs. The LoadAdaptive technology is patented and exclusive to Sun Hydraulics.

Choose LoadAdaptive™ when:

Energy and fuel efficiency is critical

A 30% lower pilot pressure is desired

The machine has a high “lift-lower-lift” duty cycle

These valves are insensitive to backpressure on port 2. Backpressure can negatively affect the function of a standard counterbalance valve by directly impacting the pressure setting, potentially causing instability and requiring higher pilot pressure to open the valve.

CW models have four ports, including a dedicated drain port downstream of the restriction.

CA models have three ports and can be retrofitted where unexpected backpressure has caused problems.

Use drained counterbalance valves in:

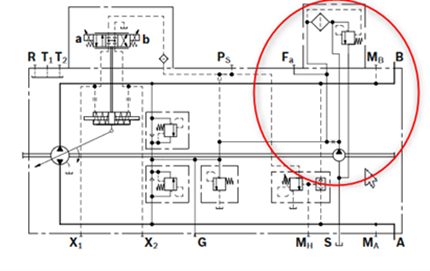

Regenerative circuits

Systems with meter-out valves, proportional valves, or servo valves

Master-slave systems

Pressures up to 420 bar

All categories of counterbalance valves are available as drained versions.

This family of counterbalance valves is designed for more demanding applications, offering the best of both worlds. They seal like a poppet valve but modulate like a spool valve. An integrated damping device ensures smooth opening and quick closing. The result is finer load control and hydraulic damping.

Choose Load-Reactive when:

Stability and motion control are critical

CB** and CW** valves become unstable despite correct sizing

Low pressure drop is needed at higher flow rates

Minimum load pressure exceeds 70 bar

These patented counterbalance valves are energy-saving and dynamically self-adjusting to approximately 1.3 times the actual load-induced pressure, while maintaining a fixed thermal relief setting. They save energy by requiring lower pilot pressure than conventional valves.

Choose LoadMatch when:

Energy and fuel efficiency are important

Stability is essential

The same movement is repeated frequently

Lower pilot pressure is desired despite wide load pressure variations

Contact one of our sales engineers for additional help and guidance — we are experts on the full range of Sun Hydraulics products.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se