It is essential to maintain a hydraulic system through preventive service measures to avoid leakage, contamination, and unplanned downtime. For example, seal kits and O-ring plates should be replaced at regular intervals. Hydnet offers a wide range of accessories for hydraulic systems to facilitate maintenance operations.

When servicing Sun Hydraulics cartridge valves, the seal kits with O-rings should be replaced to prevent leakage. Replacement intervals vary significantly depending on operating conditions. Sun Hydraulics offers several different seal kits, so it is important to consult the valve’s datasheet to determine the correct kit, or refer to the product list below. Note that valves with the same cavity may require different sealings.

The standard O-ring material from Sun Hydraulics is Buna N (nitrile), which is black in color. For hydraulic systems using specific fluids — such as glycol — or operating at temperatures exceeding 70°C, Viton O-rings (brown in color) should be used instead.

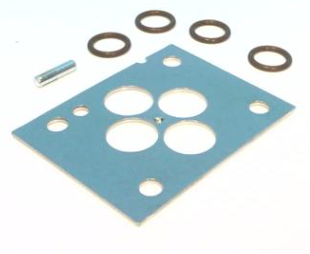

In most cases, O-ring plates are included with Sun Hydraulics sandwich manifolds. However, in some instances, they may need to be ordered separately — particularly for NG10 manifolds with X & Y ports, as these are available in both American and European configurations. When servicing a sandwich manifolds, it is advisable to replace the O-ring plate.

The O-ring plate can only be installed in one orientation, so it’s important to ensure correct alignment. The sandwich manifold being mounted on top must be positioned correctly to maintain proper function. An arrow marked with the word “NOTCH” on the manifold should point toward the small cut-out on the edge of the O-ring plate.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se