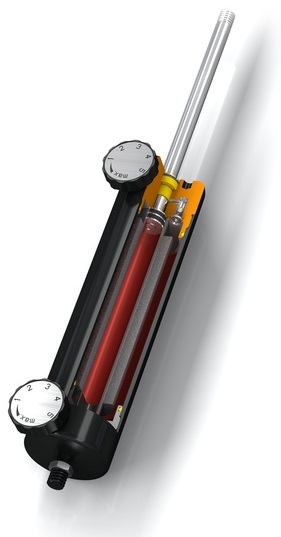

Individual speed adjustment in both directions, without free travel.

ACE Controls hydraulic dampers are robust and versatile components used to control, brake, and synchronize both linear and oscillating movements. They reduce kinetic energy and enable smooth, controlled deceleration in both extension and compression strokes – with adjustable damping depending on the model. This makes them suitable for a wide range of industries, including automotive, automation, electronics manufacturing, mechanical engineering, textile, and general industrial applications. Unlike a gas spring, which provides a constant outward force, a hydraulic damper controls the speed of movement without actively pushing the piston rod outward.

Individual speed adjustment in both directions, without free travel.

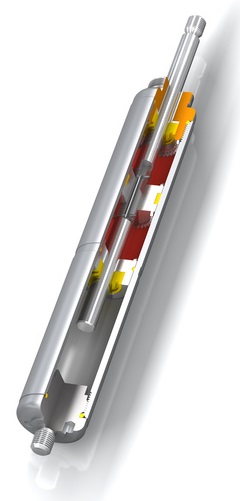

Regulation at the highest level, without free travel.

Direction change backlash free linear motion regulation, without free travel.

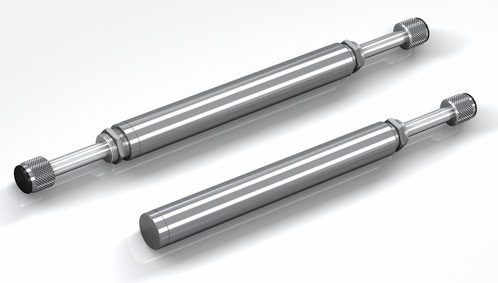

Linear motion control.

At first glance, hydraulic dampers may resemble industrial gas springs in appearance, but functionally they differ significantly. Gas springs exert a continuous pushing force that extends the piston rod automatically. Hydraulic dampers, on the other hand, do not provide any such outward force – instead, they dampen motion by forcing hydraulic oil through a precision orifice in the piston. This allows precise control of movement in both directions, without any spring-assisted motion. For applications where motion needs to be slowed rather than driven, hydraulic dampers are the preferred choice.

A hydraulic damper consists of a sealed cylinder filled with oil, a piston with adjustable throttling, a piston rod, and high-performance seals. When the piston rod moves, the oil is forced through the internal throttling system in the piston, creating a braking effect. On models with external adjustability, damping can be fine-tuned simply by rotating the piston rod in its end position – either symmetrically for both directions or individually for compression and extension. This enables precise control over speed, synchronization, and motion damping.

ACE hydraulic dampers are available in body diameters from 12 to 70 mm and stroke lengths up to 800 mm. They support forces from 30 to 40,000 N, making them suitable for everything from lightweight precision tasks to heavy industrial applications. The standard material is high-grade steel, but most models are also offered in stainless steel for use in harsh environments, such as marine or chemically aggressive conditions. A wide range of variants and accessories allows easy adaptation to different installation needs and application requirements.

Choosing the right hydraulic damper can be critical to ensuring the function and longevity of your application – but finding the ideal model isn’t always straightforward. Parameters such as force, speed, stroke length, mounting orientation, and environmental conditions all influence the selection. Contact us at Hydnet, and our experienced sales engineers will assist you with calculations, sizing, and selecting the most suitable model. We’ll ensure you get a solution that’s technically and economically optimized for your specific needs.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se