For precision adjustment of feed rates.

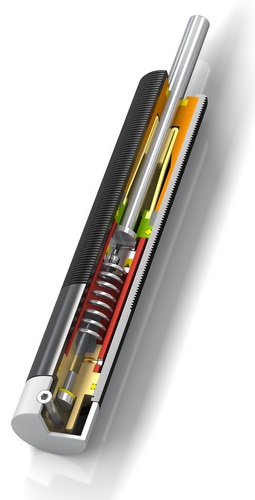

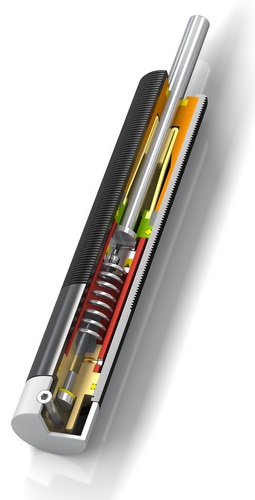

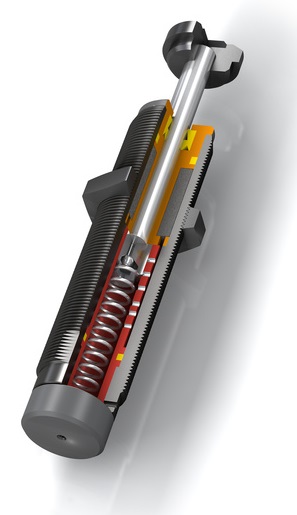

Hydraulic feed control means regulating the movement speed of the piston in a hydraulic cylinder or a corresponding moving part of the equipment by using hydraulic resistance. This allows very precise and stable speed control regardless of the load. ACE Controls’ range in this area offers solutions where the piston’s movement speed can be easily adjusted via an external control, from very low speeds of 12 mm/min up to 38 m/min. The products are designed to be compact, maintenance-free, and easy to install, making them a reliable and flexible solution to optimize production flows and improve machine operational reliability.

For precision adjustment of feed rates.

Designed for applications with low precision requirements.

Hydraulic feed control is ideally suited for applications such as sawing, drilling, milling, and other machining operations where a smooth and controlled feed rate is essential. They are also an effective aid to counteract the stick-slip effect in pneumatic cylinders, which improves precision and reduces equipment wear. Thanks to the precise speed regulation, both quality and performance in automated systems are enhanced. This technology also helps reduce downtime and extend the lifespan of machines, providing economic benefits in production environments.

ACE Controls hydraulic feed controls are complete units with built-in control via a precision throttle valve, ensuring exact and stable regulation of the feed rate. The dynamic sealing with rolling diaphragms—the same technology used in many of ACE’s shock absorbers—provides a hermetic seal and compensates for volume changes caused by the piston rod. This also enables the piston to reset automatically when the force is removed. Thanks to this design, the products are maintenance-free and highly reliable, making them an optimal component to improve precision and operational reliability in various hydraulic applications.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se