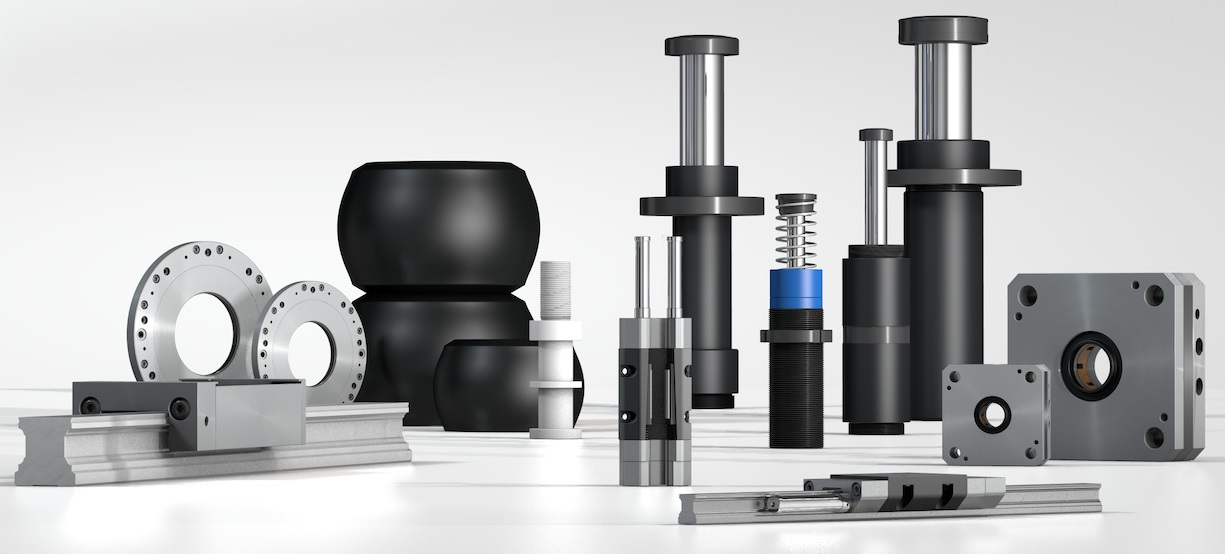

Safely slowing down damaging forces from moving loads or emergency braking are united in this product group from ACE Controls. Although the safety shock absorbers, profile dampers and clamping elements differ so much in design, every single ACE Controls component provides the best protection for your machine.

They demonstrate their main advantages in emergency stop situations and, based on the protection they provide, are very cost-effective. Furthermore, they can all be easily integrated in the existing construction designs and largely work independent of energy supplies.

To prevent serious incidents caused by, for example, control system failure or uncontrolled acceleration of machinery, safety shock absorbers are recommended. These damping solutions are designed for single-use emergency situations and should be replaced or refurbished after a stop has occurred.

The safety shock absorbers from ACE Controls demonstrate their greatest advantages in emergency stop scenarios, offering highly cost-effective protection. Furthermore, they can all be easily integrated in the existing construction designs and largely work independent of energy supplies.

Expensive production equipment or sensitive components such as circuit boards and computer hardware can be effectively protected with emergency stop systems. By quickly and safely halting the system in the event of a fault or malfunction, mechanical damage, costly repairs, and production downtime can be avoided—especially in environments where precision and electronics are critical to operations.

Typical applications where an emergency stop can be crucial include overhead cranes, heavy manufacturing industries such as steel mills and paper plants, as well as systems operating sluice gates. In these environments, an effective emergency stop system can prevent serious accidents and equipment damage—and in many cases, protect both human lives and valuable assets.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se