Sequential operation of multiple cylinders involves using blocks with sequence valves designed to activate hydraulic system functions in a specific, predetermined order. This is especially important in applications where one process step—such as clamping or securing a workpiece—must be completed before the next step, like cutting, bending, or drilling, begins. Ensuring the correct sequence improves both precision and safety in the machine’s operation while minimizing the risk of incorrect movements.

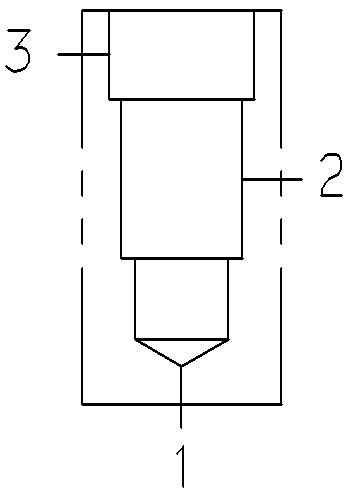

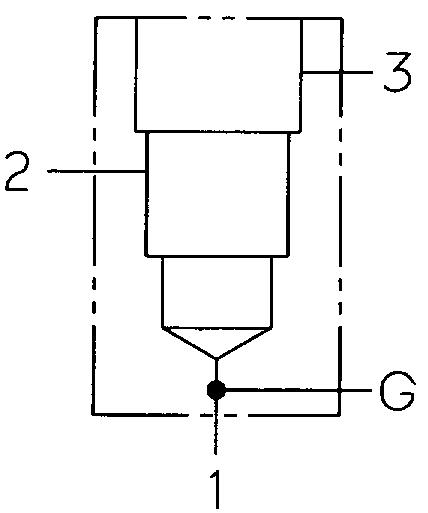

Line mount manifold for sequence valves and sequence valves with bulit-in reverse free flow. 3-ports, 90° body and gauge port.

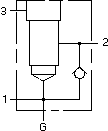

Line mount manifold for sequence valves. Sequence with reverse free flow in 90° body and gauge port.

Line mount manifold for sequence valves and sequence valves with bulit-in reverse free flow. 3-ports, pipe mounted inline body.

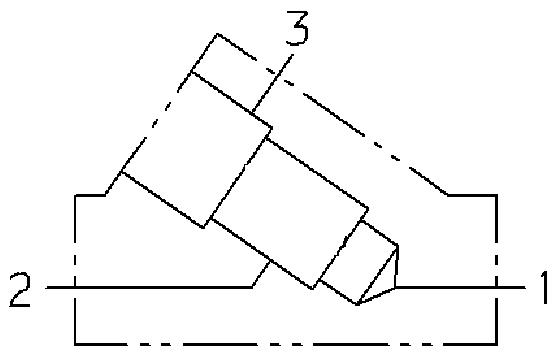

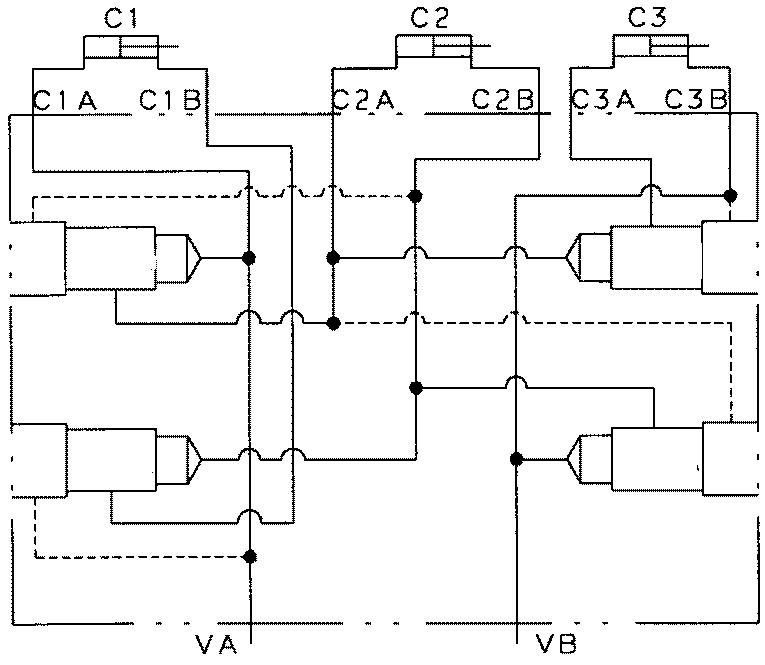

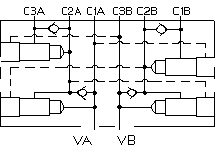

Line mount manifold for sequence valves. 3 cylinders, direct acting sequence with bulit-in reverse free flow.

Line mount manifold for sequence valves. 3 cylinders, sequence with reverse free flow.

Line mount manifolds for sequence valves and sequence valves with bulit-in reverse free flow. 3 ports, 90° body, gaugeport.

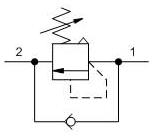

The sequence valve is set to open at a specific pressure, allowing hydraulic fluid to flow to the next function in the sequence once that pressure is reached. A key feature is that the subsequent function is not affected by the pressure downstream of the valve, ensuring each step activates only after the previous one is complete and in the correct order. To allow proper return flow and prevent the system from locking up, a check valve is required. Many hydraulic cartridges combine sequence and check valve functions into a single unit—often identified by an SC* code—simplifying installation and reducing component count. When using a block with an integrated check valve, a separate combined sequence and check valve is not needed, making the system more compact and easier to maintain.

Ready-made line-mount solutions are available in sizes up to G 1 1/4” thread, covering many common industrial and mobile hydraulic applications. The blocks come in two main materials to meet different pressure and environmental requirements: aluminum, rated for pressures up to 3000 psi (210 bar), offering a lightweight and corrosion-resistant option, and steel, suited for heavier-duty applications up to 5000 psi (350 bar). For enhanced durability and corrosion protection, the blocks can also be ordered with various surface treatments, making them suitable for harsh operating conditions and extending component life. This material and design flexibility makes sequence blocks highly adaptable to a wide range of hydraulic systems and requirements.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se