Flow divider, 1 in, 4 out, divider, pipe mounted.

Flow division is a technique for efficient control and synchronization of hydraulic flows. Sun Hydraulics flow dividers are used to split, combine, or synchronize hydraulic flows in systems where multiple cylinders or motors need to work together. This is especially important when a large flow must be distributed to several units, such as to lift, lower, or move platforms, beds, ramps, gangways, fork spreaders, or various types of attachments. Flow dividers are also often used in wheel drive systems on smaller vehicles where precise flow distribution and synchronization are required.

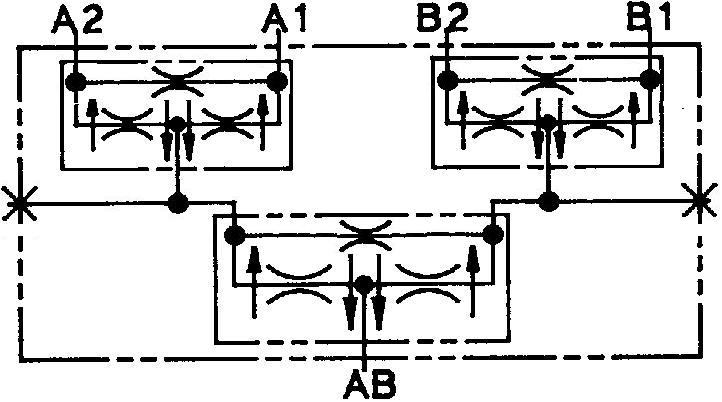

Flow divider, 1 in, 4 out, divider, pipe mounted.

Flow divider, 1 in, 4 out, divider/combiner, pipe mounted.

Flow divider, 1 in, 4 out, divider/combiner and synchronizing, pipe mounted.

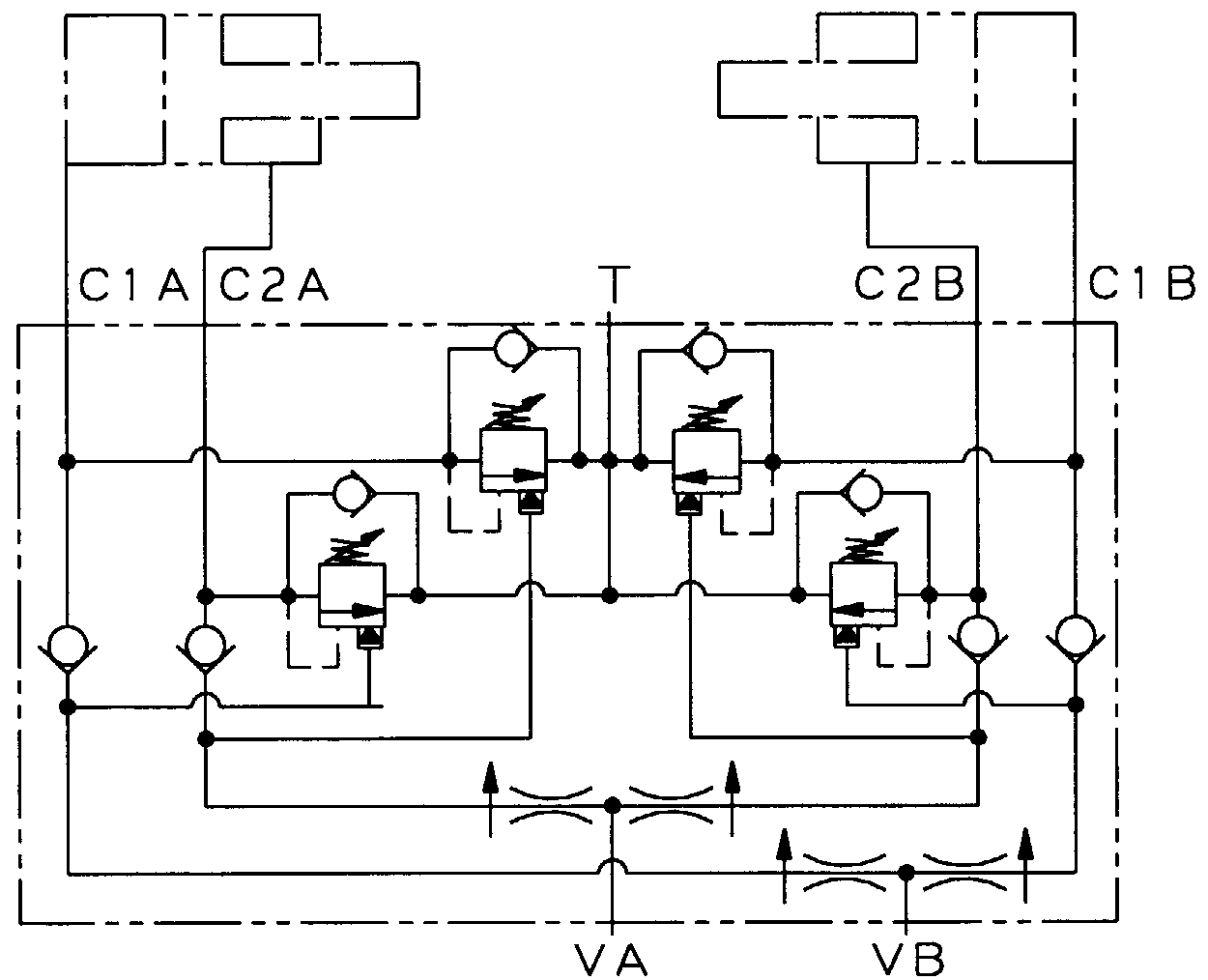

Flow divider, relief & anti cav checks with T port, pipe mounted.

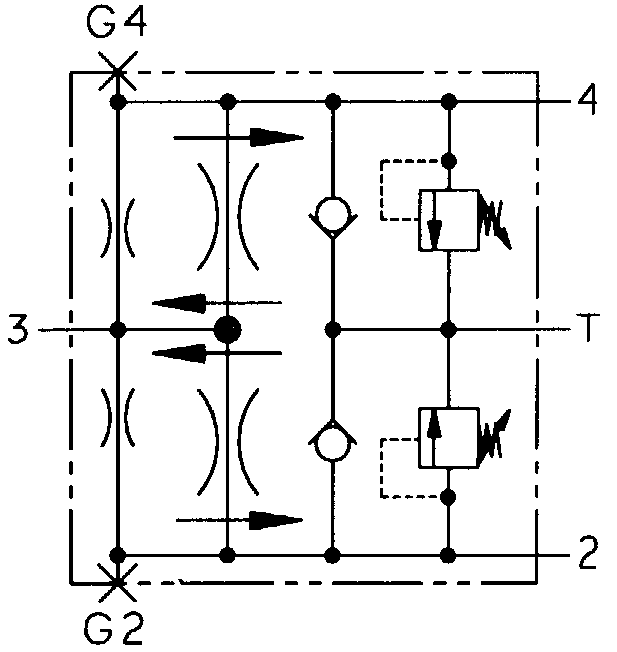

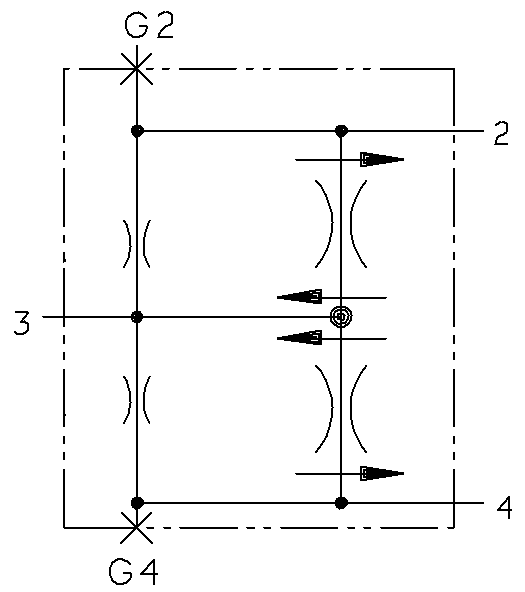

low divider, with orifices for tractive drive, pipe mounted.

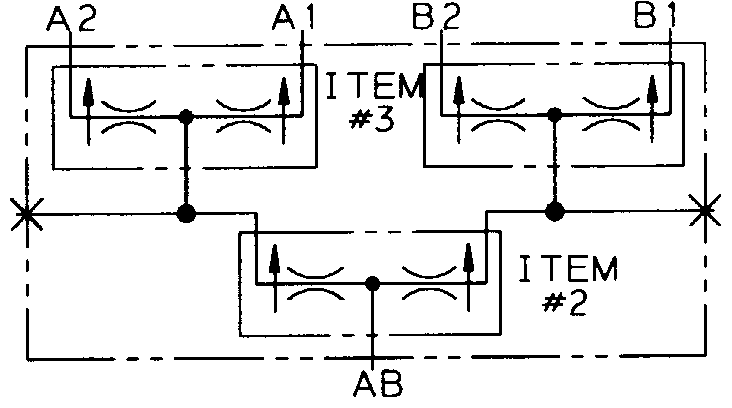

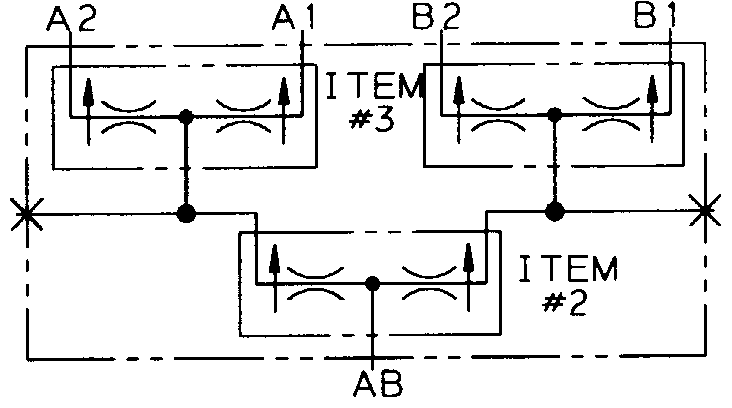

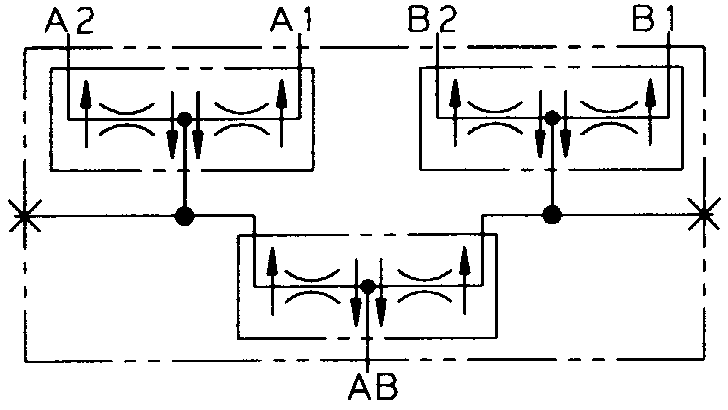

Sun Hydraulics offers several models of flow dividers with varying levels of accuracy in synchronizing cylinders at the end position. For applications with cylinders, it is common to use models that both divide the flow and collect the return flow, which increases system efficiency and reduces the need for additional return systems. Flow dividers that allow flow in only one direction are typically used with motors, ensuring each motor receives the correct flow for optimal operation.

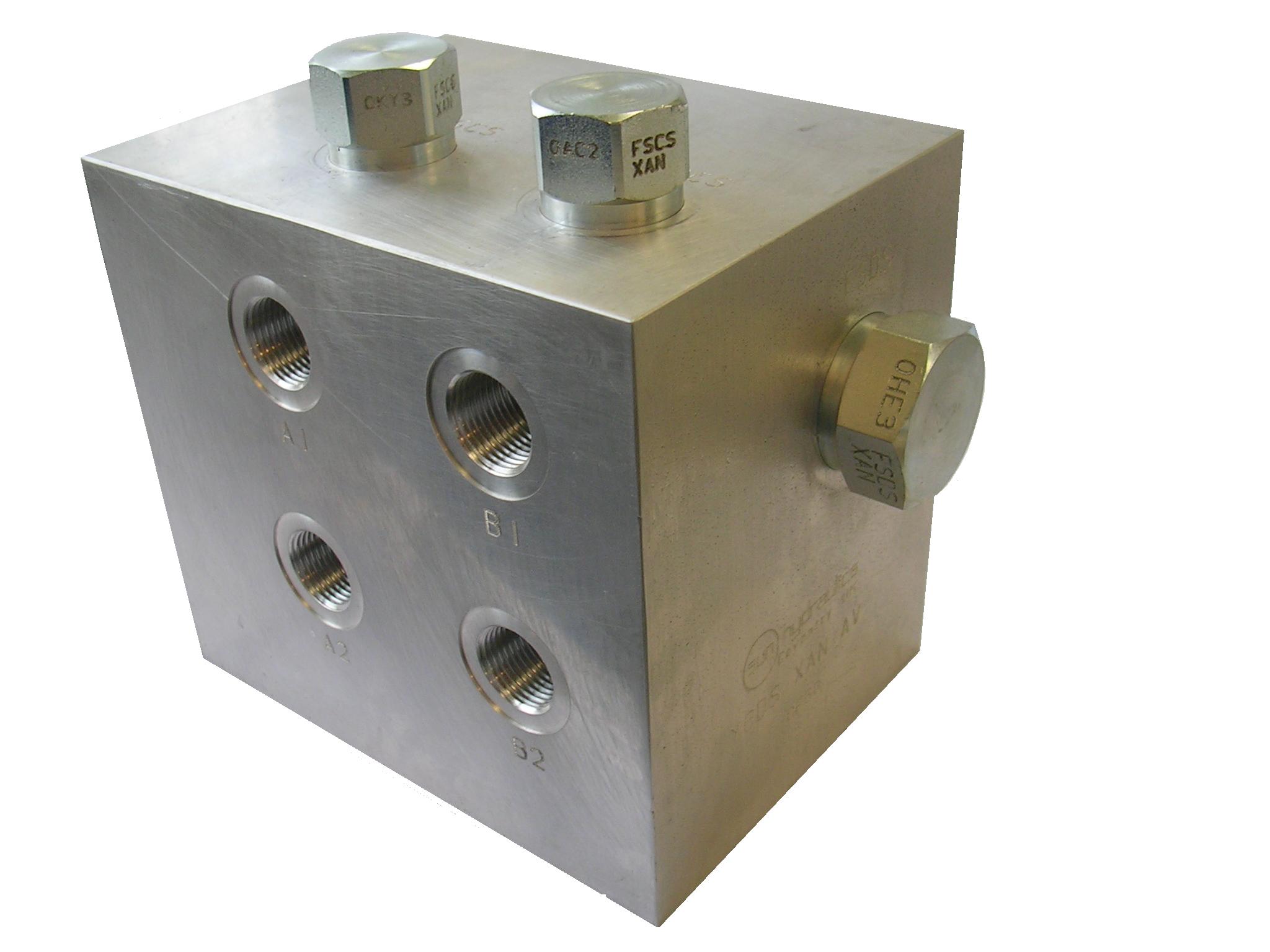

Flow dividers can be combined to create systems with one input and multiple outputs, allowing the flow division to be tailored to your specific needs. Sun Hydraulics has therefore consolidated many of these combinations into practical valve blocks that may also include other functions, such as load-holding valves or pressure relief valves, to further optimize system performance and safety.

Flow dividers are available for flow rates from 6 to 270 liters per minute and pressures up to 350 bar, covering a wide range of applications. They are available both as pipe-mounted blocks, with sizes up to SAE 1 ½” flange, and as sandwich-mounted blocks up to size NG10. Sandwich solutions often offer easier installation and flexibility in modular systems. All blocks are available in aluminum (up to 3000 psi/210 bar) and steel (up to 5000 psi/350 bar), with options for surface treatment to enhance durability and corrosion resistance, making them suitable for both light and demanding environments.

Need assistance or advice designing your hydraulic system? Please feel free to contact us — we are experts in hydraulics.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se