A 3-way directional valve, also called a 3/2 valve, has three ports and two positions. It is used to control the flow of hydraulic oil in a system by starting, stopping, or switching the flow between different functions. The valve can be operated electrically (via solenoid), manually, or through pressure changes. A 3-way directional valve is often used to control a single-acting cylinder or to connect a function to pressure or return, thereby regulating movement within the system.

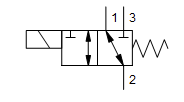

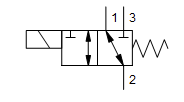

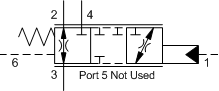

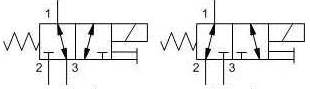

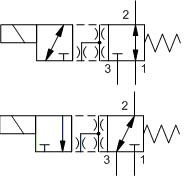

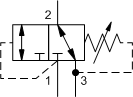

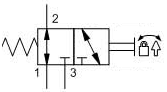

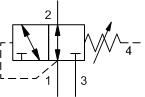

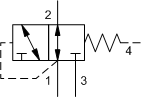

3 way, 2 position, pilot operated

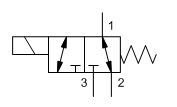

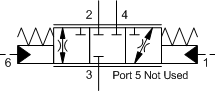

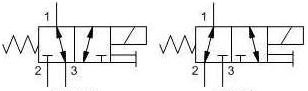

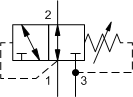

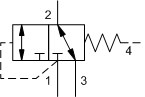

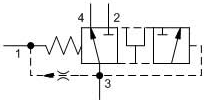

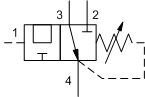

3 way, 3 position, pilot operated. Please note, the valves are no longer available. For replacement, please contact one our sales engineers.

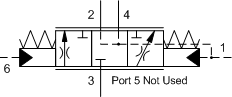

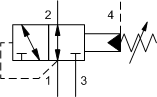

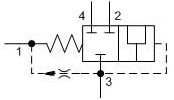

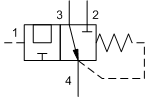

3 way, 3 position, pilot operated, center bleed down. Please note, the valves are no longer available. For replacement, please contact one our sales engineers.

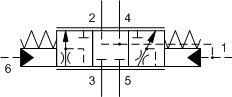

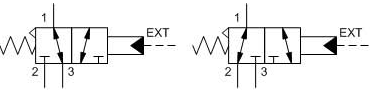

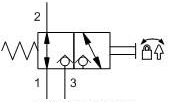

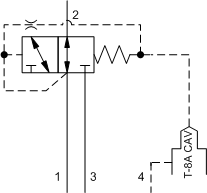

3 way, 3 position, pilot operated, center bleed down, load sense. Please note, the valves are no longer available. For replacement, please contact one our sales engineers.

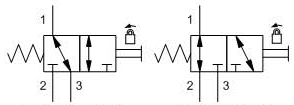

3-way, soft shift, solenoid-operated directional spool valve – pilot capacity (740 Series)

3-way, direct-acting, balanced spool, solenoid-operated directional valve, 1600 psi (110 bar) – common cavity.

3-way, FLeX series, solenoid-operated directional spool valve, direct-acting, pilot capacity. Coil options low power 3000 psi, high power 5000 psi or explosion proof.

3-way, FLeX series, solenoid-operated directional spool valve, direct-acting. Coil options high power 5000 psi or explosion proof.

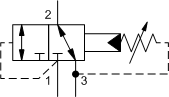

3-way, spool. Please note, DBAA and DBAL are no longer available. Replacement for both is DBAF. For more information, please contact one of our sales engineers.

3-way, spool, soft shift. Please note, DBALS is no longer available. Replacement is DBAFS. For more information, please contact one our sales engineers.

3-way, poppet. Please note, the valve is no longer available. For replacement, please contact one our sales engineers.

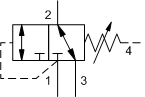

3 ports, port 2 to 3 open, port 1 blocked, pilot operated, 3-way

3 ports, port 2 to 3 open, port 1 blocked, direct acting, 3-way

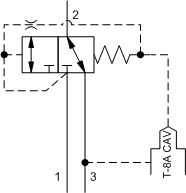

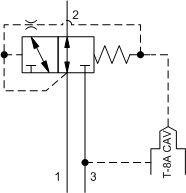

3 ports, port 2 to 3 open, port 1 blocked, integral T-8A control cavity, 3-way

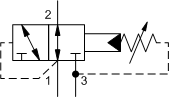

3 ports, port 1 to 2 open, port 3 blocked, pilot operated, 3-way

3 ports, port 1 to 2 open, port 3 blocked, direct acting, 3-way

3 ports, port 1 to 2 open, port 3 blocked, integral T-8A control cavity, 3-way

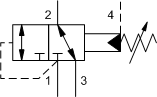

4 ports, port 2 to 3 open, port 1 blocked, pilot operated, 3-way

4 ports, port 2 to 3 open, port 1 blocked, direct acting, 3-way

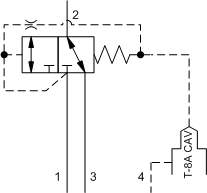

4 ports, port 2 to 3 open, port 1 blocked, integral T-8A control cavity, 3-way

4 ports, port 2 to 3 open, port 1 blocked, direct acting, fixed setting, 3-way

4 ports, port 1 to 2 open, port 3 blocked, pilot operated, 3-way

4 ports, port 1 to 2 open, port 3 blocked, direct acting, 3-way

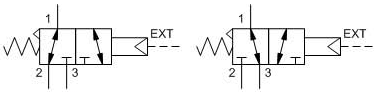

3 way, Vent to shift, normally open diverter

4 ports, port 1 to 2 open, port 3 blocked, integral T-8A control cavity, 3-way

3 way, Vent to shift, normally closed diverter

4 ports, port 1 to 2 open, port 3 blocked, direct acting, fixed setting, 3-way

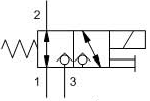

3 way, 2 position, pilot to shift

4 ports, port 3 to 4 open, port 2 blocked, direct acting, 3-way

4 ports, port 3 to 4 open, port 2 blocked, direct acting, fixed setting, 3-way

A 3-way directional valve has three ports and two positions. It is commonly used to control single-acting cylinders or as a pilot control. Depending on the valve’s position, it can either connect a pressure source to a consumer, or connect the consumer to the return line while blocking the pressure port. This makes it particularly useful in systems where a function needs to be controlled with a simple on/off command, but where pressure needs to be relieved when the function is not active.

3-way directional valves are available in two designs – poppet and spool. A poppet valve is designed to be completely leak-tight in the closed position, making it particularly suitable for load-holding applications where any leakage must be avoided. A spool valve, on the other hand, always has a certain amount of internal leakage due to its design and is commonly used in systems where minor leakage is acceptable or where fast switching is more important than complete sealing.

If there is a need to operate the directional valve manually – for example during maintenance, troubleshooting, or in emergency situations – the valve can be equipped with a manual override. These are available in two versions: with a maintained position, where the valve stays in the manual position until changed again, or with a spring-return position, where the valve automatically returns to its original state once the manual operation is released.

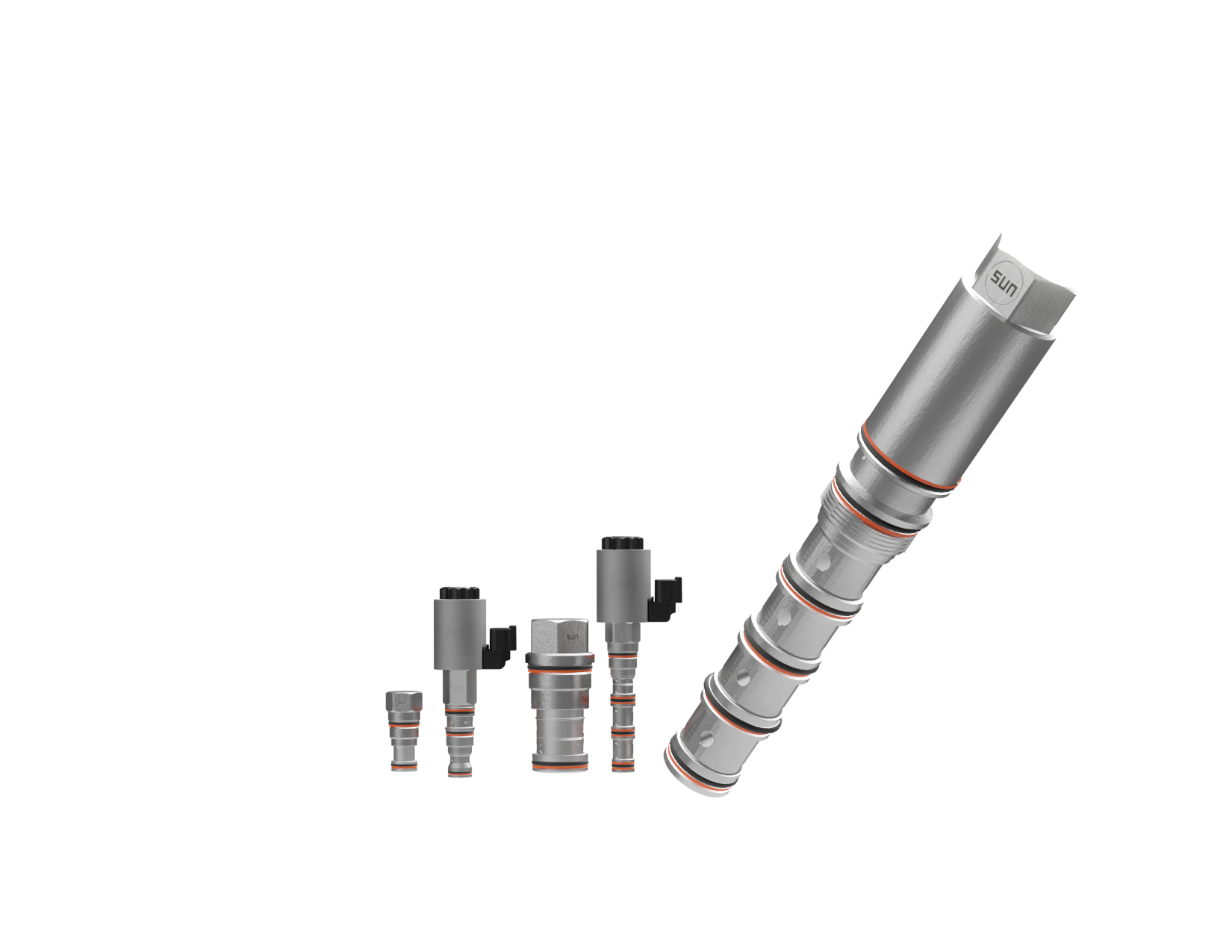

Hydnet holds the largest stock of Sun Hydraulics cartridge valves in Europe, enabling immediate delivery – in urgent cases, we can often deliver the same day. When you choose Sun Hydraulics, you can be completely confident in your decision. Each cartridge valve is manufactured to the highest quality standards and undergoes thorough testing, with every unit tested individually before it leaves the factory. This ensures outstanding performance and maximum operational reliability.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se