A selector valve (also called a function selector valve) is used to switch between two or more functions using a common control signal or actuator. It enables control of multiple hydraulic functions, such as cylinders or motors, from the same valve, but always one function at a time. The main purpose of the selector valve is to direct the flow to the selected function while stopping flow to the other functions, which simplifies the system design and reduces the need for multiple separate valves.

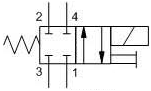

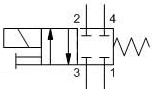

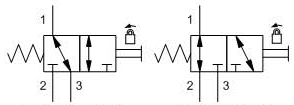

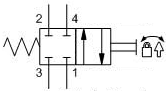

4 way, 2 position, closed transition, solenoid operated with position indicating switch

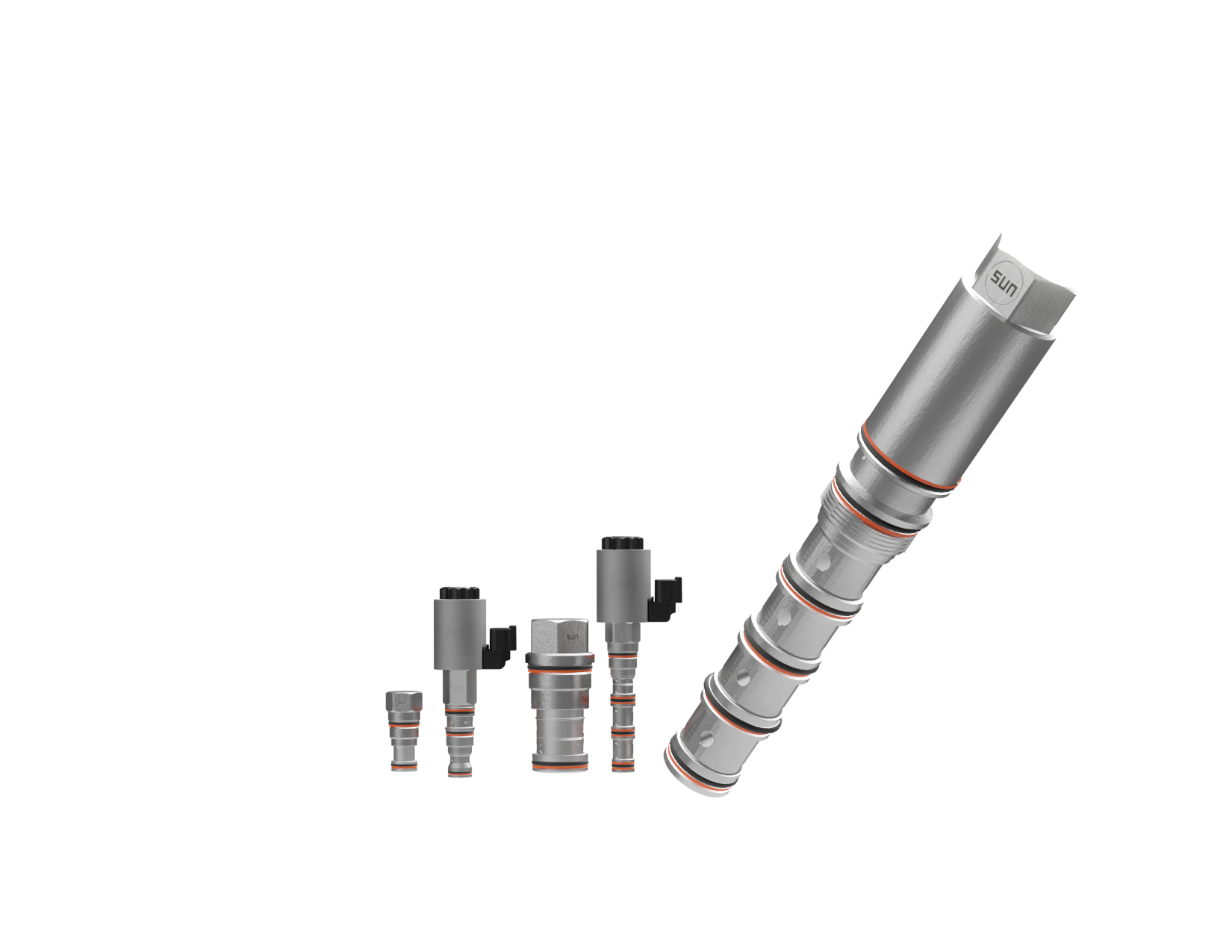

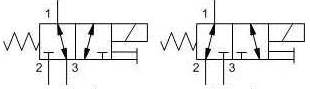

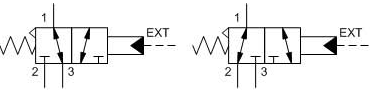

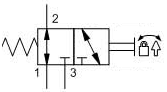

3-way, spool. Please note, DBAA and DBAL are no longer available. Replacement for both is DBAF. For more information, please contact one of our sales engineers.

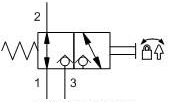

3-way, spool, soft shift. Please note, DBALS is no longer available. Replacement is DBAFS. For more information, please contact one our sales engineers.

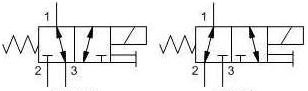

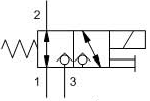

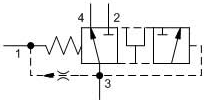

3-way, poppet. Please note, the valve is no longer available. For replacement, please contact one our sales engineers.

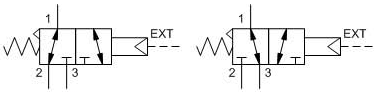

3 way, Vent to shift, normally open diverter

3 way, 2 position, pilot to shift

A selector valve is a hydraulic valve used to switch between two or more functions using a common control signal or actuator. It enables multiple functions, such as cylinders or motors, to be controlled from the same valve—although only one function at a time. This simplifies the system design while saving both space and cost.

A selector valve typically has one inlet connected to the control valve or pressure source, and several outlets to different functions. A control port or manual lever determines which outlet is active at any given time. When the valve is activated in a certain position, flow is directed to the selected function while the other outlets are blocked. This allows multiple movements to be controlled from the same control section without interfering with each other. Common applications for selector valves are hydraulic systems in sectors such as agriculture, construction machinery, material handling and the automotive industry, where the control of multiple functions with a single control unit is desired.

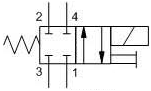

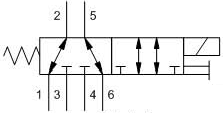

A 3/2 valve, with three ports and two positions, is a common type of selector valve used to switch a pressure line between two different functions. It allows multiple functions to be controlled with the same directional valve, simplifying the system and saving space. Such valves are used, for example, in construction machinery where you can switch between using the bucket or the grapple on an excavator or on tractors where the same selector valve can control both the lift arm and the tipping trailer.

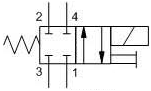

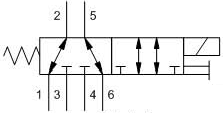

When both pressure and return lines are required, a 6/2 valve with six ports and two positions is used instead. This type of valve is ideal when adding an extra function to an existing hydraulic system without installing additional directional valves. By switching between two functions with the same control signal, the installation becomes simpler and more space-efficient. 6/2 valves are common in agricultural machinery and tractors where new hydraulic functions are added while retaining the original valve setup.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se