A compensator valve is a valve that automatically compensates for changes in load pressure or load, allowing the flow to a consumer to be regulated steadily and accurately without being affected by variations in the load. This ensures consistent operation and optimal performance in hydraulic systems, even when load conditions change.

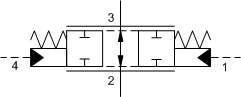

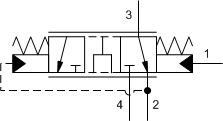

Bi-directional, modulating

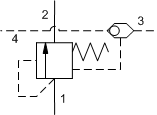

Bypass/Restrictive, modulating

There are different types of compensator valves designed for systems with either fixed or variable pumps. In systems with fixed pumps, compensator valves are often used to shunt excess flow and thereby protect the system from overload by leaking off a portion of the flow. A compensator valve can also be combined with a flow control valve to create a priority valve with a bypass function. The prioritized flow is set by the flow control valve, while the remaining flow passes through the compensator valve to a secondary function.

In systems with variable pumps, restrictive compensator valves are used to limit and regulate the flow to the consumer. These compensator valves also enable load-sensing control, such as LS copying (Load Sensing), where the pump’s flow and pressure are adjusted according to the current load to increase efficiency and reduce energy consumption.

A compensator valve is particularly valuable in hydraulic systems where the load can vary significantly, and where it is crucial to maintain stable flow or pressure regardless of these changes. By compensating for load variations, the valve ensures that machine functions consistently receive the correct amount of oil at the right pressure, improving precision, performance and system longevity.

Compensator valves are commonly used in mobile hydraulics, such as in excavators, wheel loaders, cranes, and forestry machinery, where varying loads occur frequently during lifting, digging or handling of heavy loads. These valves help maintain a stable flow, enabling smooth and controlled movements regardless of the load. They are also used in hydraulic presses, lift tables, stackers and in load-sensing (LS) systems to optimize energy use and ensure rapid response to load changes.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se