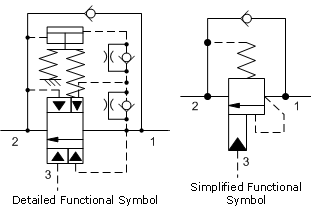

3 ports, non-vented, self-adjusted

LoadMatch counterbalance valves, developed by Sun Hydraulics, are specifically designed to optimize performance in applications with variable loads and flow rates, where safety, energy efficiency, and battery operation are critical factors. The valve automatically adjusts to 1.3 times the current load, making it ideal for systems experiencing significant load pressure variations. This dynamic adjustment ensures stable operation while reducing unnecessary energy consumption, contributing to greater system efficiency and extended operating times, particularly in electric and battery-powered hydraulic solutions. Additionally, LoadMatch effectively eliminates jerky movements when lowering loads, as its precise flow regulation enables smooth and predictable motion, even at low flow rates.

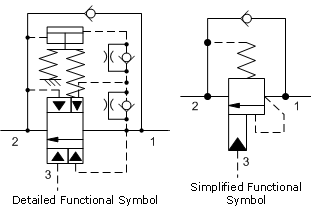

3 ports, non-vented, self-adjusted

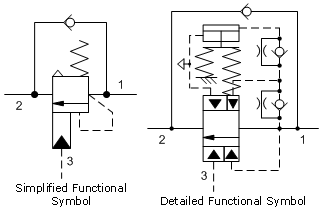

3 ports, atmospherically vented, self-adjusted

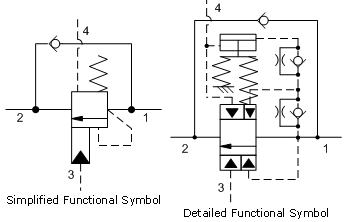

4 ports, vented, self-adjusted

The LoadMatch load holding valve continuously adjusts to 1.3 times the current load, making it ideal for applications with significant variations in load pressure. This dynamic regulation ensures smooth and stable operation, even as the load changes during movement, guaranteeing optimal performance without the need for manual adjustments.

A conventional load holding valve must be set to 1.3 times the maximum load, which can create challenges in systems where the load varies significantly. One example is a hook-lift truck, which must hold a fully loaded container but also return with empty arms, meaning no load at all. In such situations, the pilot pressure still needs to overcome the setting for 1.3 times the maximum load, but without the assistance of the load itself. This results in high pressures in pilot lines, increased system strain, and excessive wear on hydraulic components. The LoadMatch series solves this issue by automatically adjusting the pressure setting to match the actual load, allowing the system to handle large variations without compromising safety or efficiency.

The pilot pressure required to open LoadMatch and lower an empty load is significantly lower than for a standard valve, which must always operate against 1.3 times the maximum possible load. Thanks to this optimized pressure regulation, LoadMatch can reduce energy consumption by up to 30%, making it an excellent choice for applications where energy efficiency is crucial. This technology makes LoadMatch particularly well-suited for battery-powered systems and hybrid-electric applications, where low energy consumption is key to maximizing runtime and operational efficiency. By optimizing the hydraulic function, it also reduces strain on system components, leading to longer lifespan and greater reliability.

LoadMatch provides an exceptional level of safety, as it is completely adjustment-free. The settings are automatically managed within the valve, eliminating the risk of incorrect adjustments or unintended modifications. This makes the valve highly secure and reliable, while also simplifying installation and operation, with no need for manual calibration.

By reducing the average operating pressure, LoadMatch actively helps to minimize heat buildup in hydraulic systems. This not only prevents overheating but also protects other system components from degradation or failure over time. Thanks to its efficient pressure regulation, LoadMatch enhances operational safety and extends the lifespan of hydraulic systems, especially in applications where heat management is a critical factor.

The LoadMatch load holding valve is designed with an extended nose compared to standard load holding valves, allowing it to effectively handle both small and large flow rates. This design improves valve performance during load movement and eliminates issues such as jerky, bouncing or abrupt lowering motions. These unwanted movements often occur when the valve opens but the flow is too low to maintain pressure, causing the valve to close, rebuild pressure, reopen excessively, and then close again—a cycle that leads to instability and unpredictable motion within the system. With its longer nose, LoadMatch enables a more proportional opening, ensuring a smooth and controlled lowering of the load. Even at very low flow rates, pressure is maintained, keeping the valve open to allow for soft, consistent load descent, resulting in more predictable and reliable operation.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se