Pilot-operated check valves are the simplest type of valve for load holding. They have only two positions—open or closed—which means they cannot regulate the movement of the load gradually. The valve opens when the pilot pressure exceeds a certain threshold, allowing free flow. When the pressure drops, the valve automatically closes, preventing backflow, making it particularly suitable for applications where load holding is essential. This function provides a simple yet effective solution for ensuring stability in hydraulic systems.

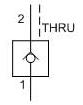

3 ports, pilot-to-open, standard pilot, steel seat, external pilot

3 ports, pilot-to-open, fixed orifice, sealed pilot, steel seat

3 ports, pilot-to-open, sealed pilot, steel seat, vent to air

4 ports, pilot-to-open, sealed pilot, steel seat, vented

3 ports, pilot-to-open, sealed pilot, steel seat, insert style

3 ports, pilot-to-open, pilot 5:1, steel seat

The simplest valve intended for holding loads is a pilot operated check valve. However, this type of valve only has an open or closed positions, and is unable to control the movement of the load. It is also unsuitable for applications where the load is transferred over a vertical position, as it risks moving away. In that case it’s better to choose a load holding valve that is often called “over center-valve”. Additionally, pilot-operated check valves lack a relief function, which is essential to protect the system against pressure buildup due to thermal expansion. While pilot-operated check valves are well-suited for simple applications, in cases where control, safety, or stability is critical, a load holding valve is the better choice. Pilot-operated check valves and load holding valves generally share the same cavity, making them interchangeable in most cases.

If there is downstream back pressure, it can counteract the opening of a pilot-operated check valve, potentially leading to undesired operational issues. To address this, it is advisable to select a pilot-operated check valve with drainage. The drainage function ensures that the back pressure does not affect the pilot control, allowing the valve to open as intended and preventing it from remaining closed due to pressure influence.

Pilot-operated check valves function by opening with the help of pilot pressure, which is typically drawn from the opposite side of the actuator. In their basic state, they work like conventional check valves, allowing flow in one direction while preventing backflow. One of the most common applications is where double load holding valves are used, where two pilot-operated check valves are used to lock a hydraulic cylinder or motor. This ensures that the load remains in a stable position without unintended movement, which is crucial for applications requiring precise positioning and load holding. Applications where double load holding valves are used are common in mobile hydraulics, industrial machinery, and crane equipment, where safety and control are key factors.

Hydnet has Europe’s largest stock of Sun Hydraulics cartridge valves, enabling immediate delivery—if needed, we can deliver on the same day. When choosing Sun Hydraulics, you can be completely confident in your selection. Each cartridge valve is manufactured to the highest quality standards and undergoes rigorous testing, with every unit individually tested before leaving the factory.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se