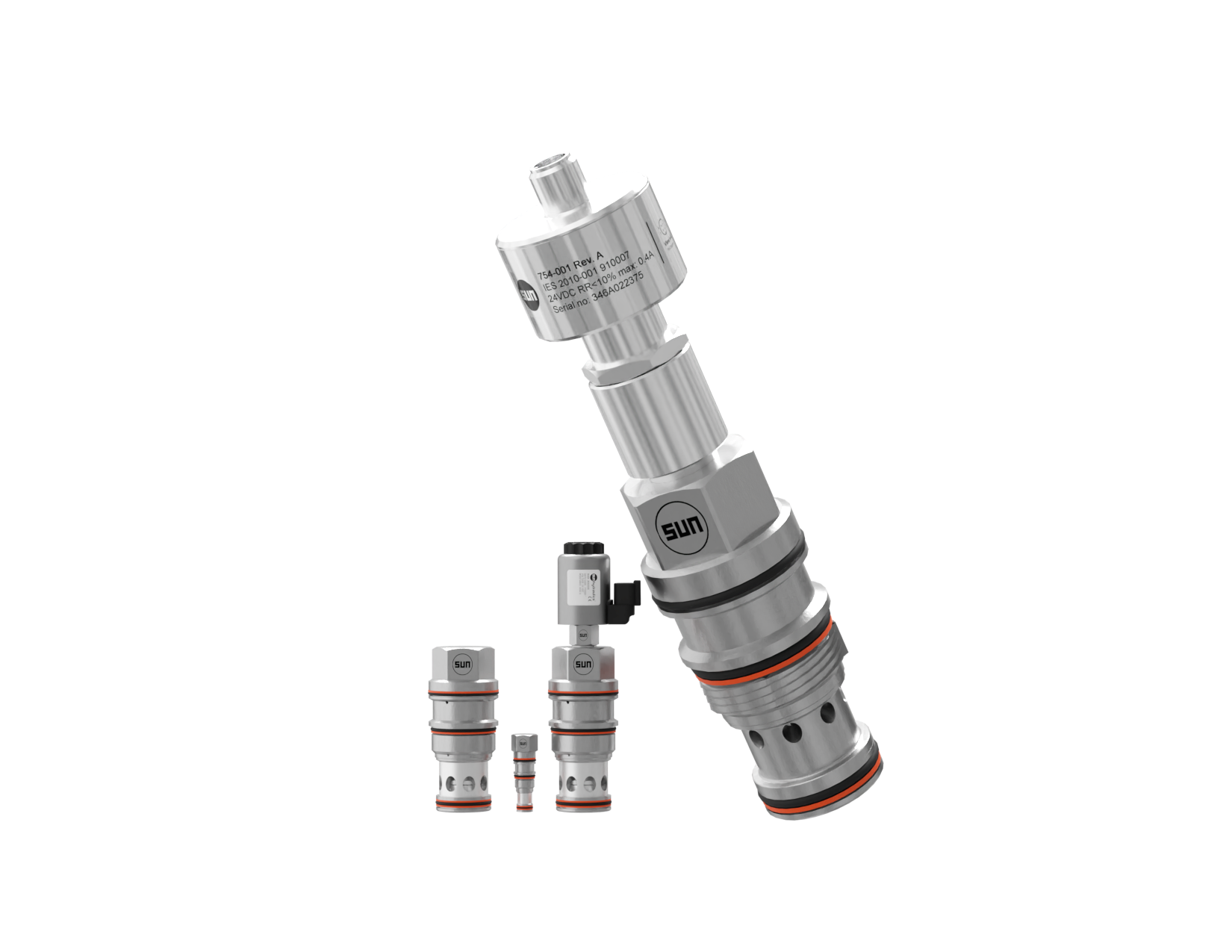

Pressure compensating logic elements are specifically designed to compensate for changes in load levels within a hydraulic system, enabling precise flow control regardless of load variations. When the load changes, system pressure can be affected, which would normally lead to fluctuations in flow and, consequently, in system performance. Pressure compensating logic elements eliminate this effect by automatically adjusting to maintain a constant flow or pressure, despite variations in load magnitude or resistance.

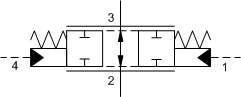

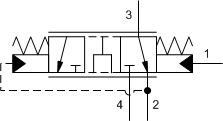

Bi-directional, modulating

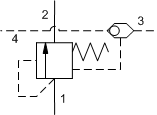

Bypass/Restrictive, modulating

The function of pressure compensating logic elements is essential in applications where precise flow control is required to ensure stable and predictable operation—for example, in presses, robotic control systems, or machines with sequential movements. The valve adjusts its opening based on the pressure drop across it—a built-in spring-loaded spool regulates the flow passage to maintain a constant pressure differential, which in turn ensures a steady flow. Pressure compensating logic elements help reduce wear and extend the system’s service life by avoiding unnecessary pressure spikes and flow fluctuations.

By maintaining a constant flow regardless of load variations, pressure compensating logic elements also improve energy efficiency in hydraulic systems, ensuring that only the amount of energy required for the specific task is used. This makes them particularly valuable in modern, energy-efficient machines and industries where sustainability and cost-effectiveness are key priorities.

There are different types of pressure compensating logic elements designed for systems with either fixed or variable displacement pumps. In systems with a fixed pump, compensators are used to divert excess flow, ensuring that the flow to the actuator remains constant despite variations in load or system demand. With this type of compensator, it is also possible to create a so-called priority valve with a bypass function, where a specific flow is prioritized and the surplus is redirected to other functions.

In systems with variable pumps, restrictive pressure compensating logic elements are used to control the flow to the actuator in a precise and regulated manner. This type of compensator is particularly suitable when optimizing energy usage and achieving high precision in flow control is critical. These elements also play an important role in load-sensing systems, where they can be used for so-called LS copying (Load-Sensing replication). This means that the signal pressure from one actuator is duplicated to control the pump’s displacement, resulting in a highly efficient and responsive system.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se