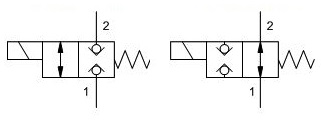

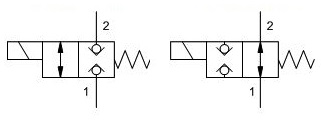

2-way, FLeX series, solenoid-operated directional blocking poppet valve, direct-acting. Coil options low power 3000 psi, high power 5000 psi or explosion proof.

A pilot valve is used to control other valves or functions by utilizing a smaller control pressure—known as pilot pressure—to open, close, or regulate a larger main valve. The pilot valve is typically electrically actuated, which in turn hydraulically controls the main valve. Pilot valves are commonly used when the main valve requires more force than a solenoid coil can generate. There are two main types of pilot valves: directional on/off pilot valves (which simply open or close the flow) and proportional pressure control pilot valves (which allow for stepless and precise pressure regulation). A 2-way pilot valve is an on/off type.

2-way, FLeX series, solenoid-operated directional blocking poppet valve, direct-acting. Coil options low power 3000 psi, high power 5000 psi or explosion proof.

A 2-way pilot valve is a simple on/off valve. The valve controls the pilot pressure by either opening or closing the flow in the pilot line, which in turn activates or deactivates the main valve. Since the valve only opens or closes the pilot flow, it is often used when quickly applying or releasing pilot pressure is sufficient to control the main valve.

2-way pilot valves are available in normally open (N/O) and normally closed (N/C) versions. Depending on the type, the valve either allows pilot flow in the idle position (normally open) or blocks it (normally closed), ensuring proper control of pilot pressure to the main stage valve.

2-way pilot valves from Sun Hydraulics feature the T-8A cavity, allowing them to be mounted directly in the main stage valve for optimal space utilization. When ordering, remember to specify the main stage valve with an integrated T-8A cavity to ensure a smooth and compact installation.

To electrically control the valve function, both simple and user-friendly amplifiers and I/O units are available. This enables smarter and more automated solutions through electronic feedback of flow, pressure, or temperature, allowing precise regulation and optimization of hydraulic functions in real time. Please contact one of our sales engineers, we will help you find the right components for your needs.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se