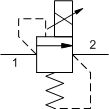

2 ports, electro-proportional relief valve – pilot capacity, high pressure setting with no command

A pilot valve is used to control other valves or functions by utilizing a smaller control pressure—known as pilot pressure—to open, close, or regulate a larger main valve. The pilot valve is typically electrically actuated, which in turn hydraulically controls the main valve. Pilot valves are commonly used when the main valve requires more force than a solenoid coil can generate. There are two main types of pilot valves: directional on/off pilot valves (which simply open or close the flow) and proportional pressure control pilot valves (which allow for stepless and precise pressure regulation).

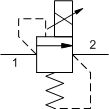

2 ports, electro-proportional relief valve – pilot capacity, high pressure setting with no command

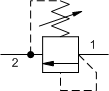

2 ports, direct acting, pilot capacity

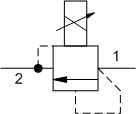

2 ports, electro-proportional relief valve – pilot capacity

A pressure control pilot valve is used in a wide range of applications where it is important to maintain a constant pressure or ensure that the pressure does not exceed a certain limit. Typical examples include hydraulic presses, fan control in machinery or the regulation of large valves.

A pressure control pilot valve regulates the flow of hydraulic oil by using a pilot pressure that activates the valve. When the system pressure reaches the preset level, the valve is activated and opens a passage to reduce the pressure or maintain it at a constant level. If the system pressure exceeds the set value, the valve opens to release the excess pressure, preventing potential damage to the system.

The most common model of pressure control pilot valves is the RBAP. It ensures minimum pressure in the unactuated state. There is also an inverted version, the RBAN, which instead provides the set maximum pressure when the valve is in the unactuated state. This function is used, for example, in fan control systems where it is crucial that machines always receive sufficient cooling to ensure optimal operation.

To control the valve function electrically, both simple and user-friendly amplifiers and I/O units are available. This enables smarter and more automated solutions through electronic feedback of flow, pressure, or temperature, allowing precise regulation and optimization of hydraulic functions in real time.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se