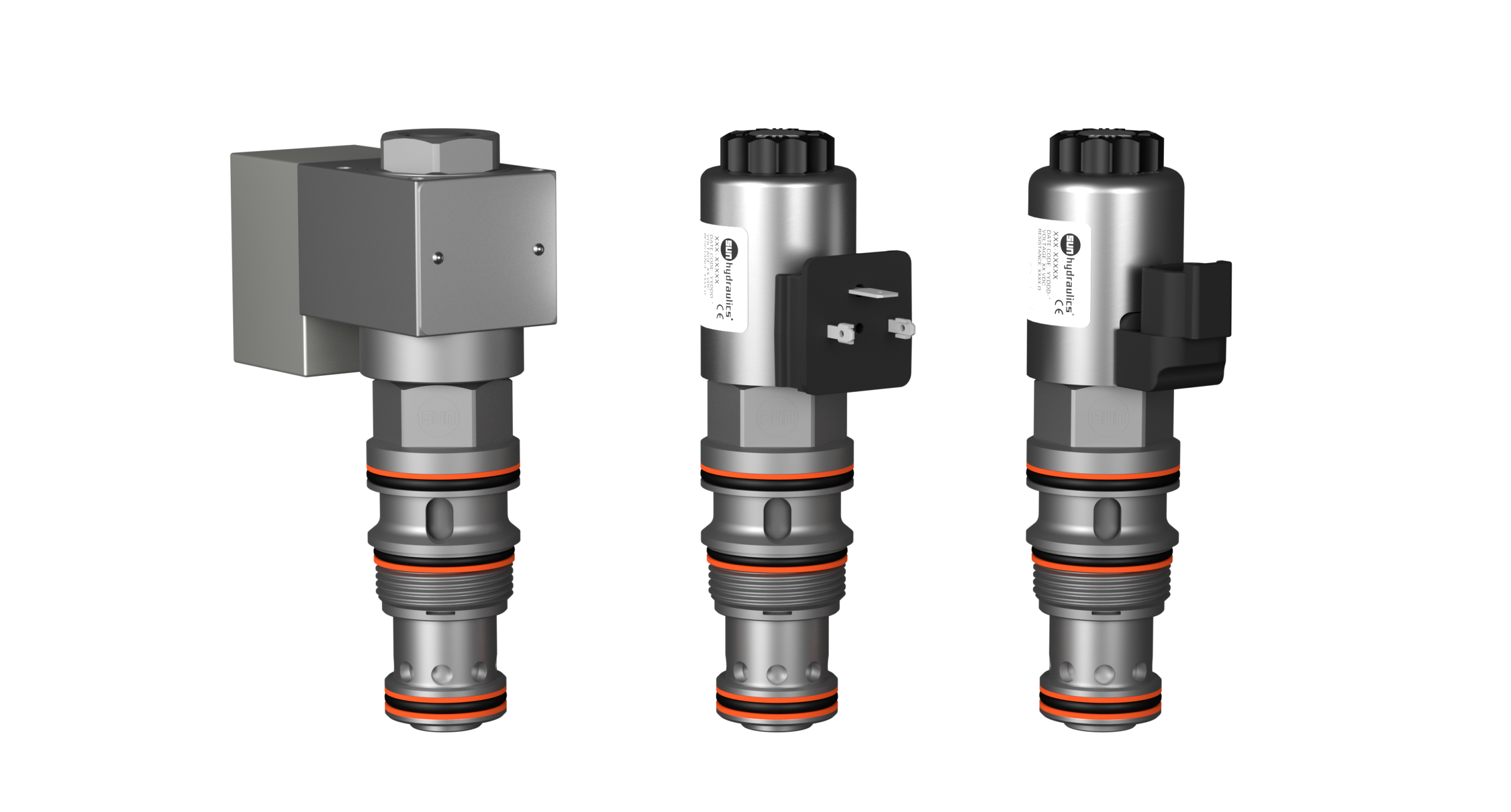

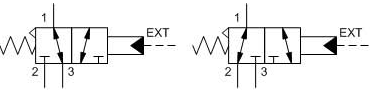

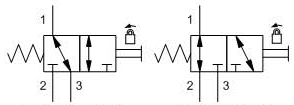

3-way, soft shift, solenoid-operated directional spool valve – pilot capacity (740 Series)

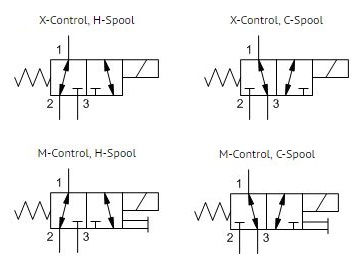

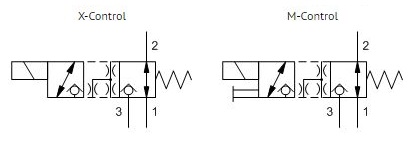

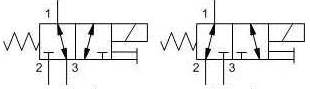

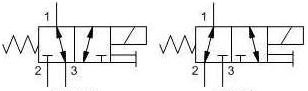

A 3-way solenoid directional valve, also called a 3/2 valve, has three ports and two positions. It is used to control the flow of hydraulic oil in a system by starting, stopping, or switching the flow between different functions. The valve is operated by an electrical signal that activates solenoids, which move a spool inside the valve. A 3-way directional valve is often used to control a single-acting cylinder or to connect a function to pressure or return, thereby regulating movement within the system.

3-way, soft shift, solenoid-operated directional spool valve – pilot capacity (740 Series)

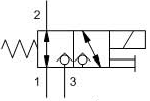

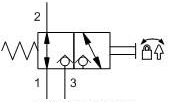

3-way, direct-acting, balanced spool, solenoid-operated directional valve, 1600 psi (110 bar) – common cavity.

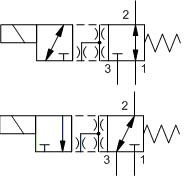

3-way, FLeX series, solenoid-operated directional spool valve, direct-acting, pilot capacity. Coil options low power 3000 psi, high power 5000 psi or explosion proof.

3-way, FLeX series, solenoid-operated directional spool valve, direct-acting. Coil options high power 5000 psi or explosion proof.

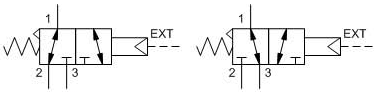

3-way, spool. Please note, DBAA and DBAL are no longer available. Replacement for both is DBAF. For more information, please contact one of our sales engineers.

3-way, spool, soft shift. Please note, DBALS is no longer available. Replacement is DBAFS. For more information, please contact one our sales engineers.

3-way, poppet. Please note, the valve is no longer available. For replacement, please contact one our sales engineers.

A 3-way solenoid directional valve has three ports and two positions. It is commonly used to control single-acting cylinders or as a pilot control. Depending on the valve’s position, it can either connect a pressure source to a consumer, or connect the consumer to the return line while blocking the pressure port. This makes it particularly useful in systems where a function needs to be controlled with a simple on/off command, but where pressure needs to be relieved when the function is not active.

3-way solenoid directional valves are available in two designs – poppet and spool. A poppet valve is designed to be completely leak-tight in the closed position, making it particularly suitable for load-holding applications where any leakage must be avoided. A spool valve, on the other hand, always has a certain amount of internal leakage due to its design and is commonly used in systems where minor leakage is acceptable or where fast switching is more important than complete sealing.

There is a wide range of solenoids available for solenoid directional valves, with various contact configurations and voltage levels to choose from. Common contact types include Hirschmann and Deutsch, and the solenoids are available for both 12V and 24V. For specific needs, there are also solenoids for alternating current (AC) with built-in rectifiers, as well as ATEX-certified versions for use in explosive environments where special safety requirements apply.

To control the solenoid valve, we offer simple and user-friendly amplifiers and I/O units. This enables smarter and more automated solutions through electronic feedback of parameters such as flow, pressure, or temperature, providing precise control over hydraulic functions. To find the right solution for your system, please contact us — we’ll be happy to assist you.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se