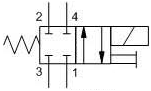

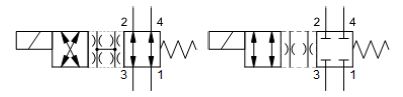

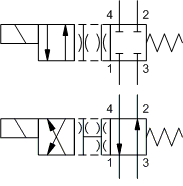

4-way, 2 position

A 4-way solenoid directional valve, also called a 4/2 or 4/3 valve, has four ports and either two or three positions. It is used to control the flow of hydraulic oil in a system through electrical actuation (known as a solenoid valve). The valve’s function is to determine the path the fluid takes — for example, whether it goes to a cylinder to extend it or to another port to retract it. This allows the valve to start, stop, or switch the flow between different functions, making it central to controlling double-acting cylinders and other hydraulic components.

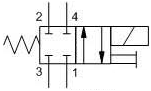

4-way, 2 position

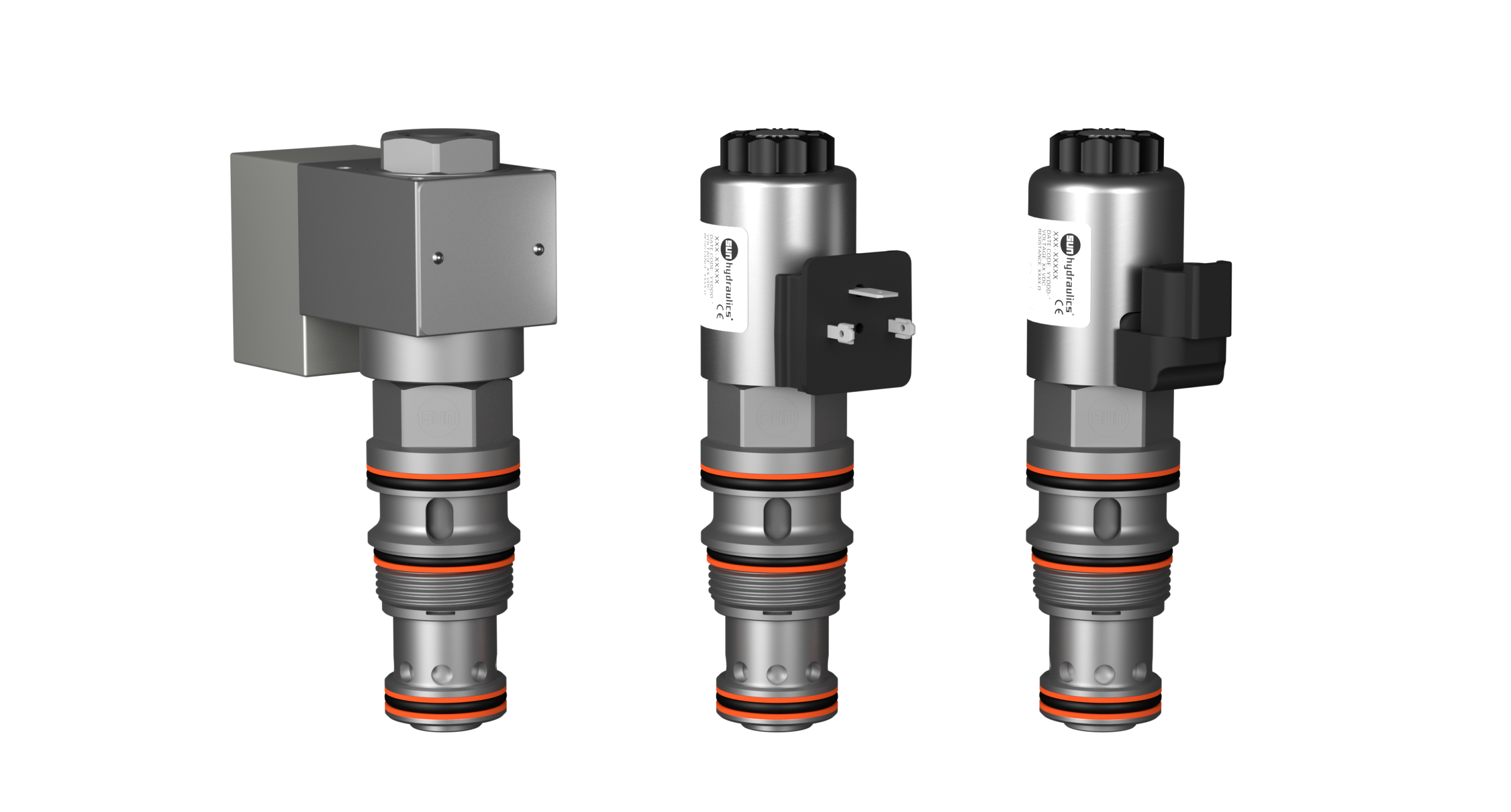

4 way, 2 position, closed transition, solenoid operated with position indicating switch

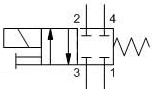

4-way, direct-acting, balanced piston solenoid-operated directional valve, 3000 psi (210 bar) – common cavity.

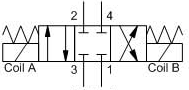

A 4-way solenoid directional valve has four ports and either two or three positions. It is commonly used to control double-acting cylinders where the flow can be directed in both directions, and the valve may have a neutral position to stop or allow the flow to circulate. The three positions can, for example, be: one position to extend the cylinder, one position to retract it, and a neutral position where both ports are either closed or connected to the tank to hold the load in position or allow free flow.

4-way solenoid directional valves are used in many hydraulic systems where double-acting cylinders are required, such as industrial machinery, lifting equipment, and vehicle applications. They provide precise control of cylinder movements and ensure that the force can be directed and held safely and efficiently. Thanks to the neutral position, the system can be adapted both to lock the position and to reduce energy consumption when movement is not needed.

There is a wide range of solenoids available for solenoid directional valves, with various contact configurations and voltage levels to choose from. Common contact types include Hirschmann and Deutsch, and the solenoids are available for both 12V and 24V. For specific needs, there are also solenoids for alternating current (AC) with built-in rectifiers, as well as ATEX-certified versions for use in explosive environments where special safety requirements apply.

To control the solenoid valve, we offer simple and user-friendly amplifiers and I/O units. This enables smarter and more automated solutions through electronic feedback of parameters such as flow, pressure, or temperature, providing precise control over hydraulic functions. To find the right solution for your system, please contact us — we’ll be happy to assist you.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se