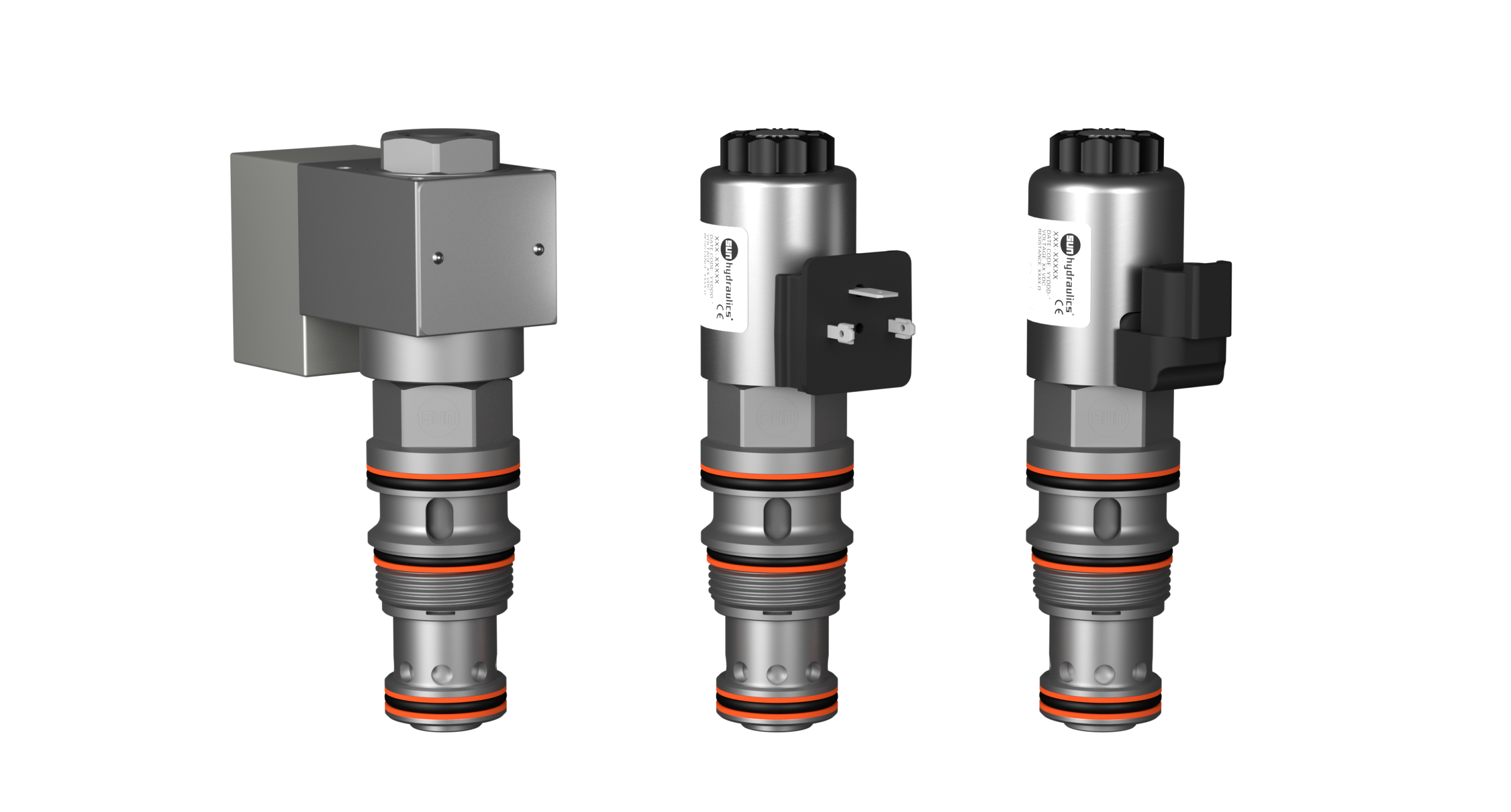

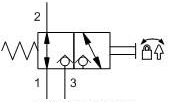

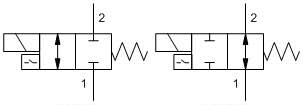

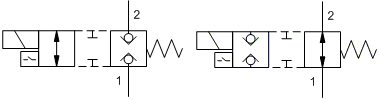

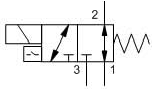

4 way, 2 position, closed transition, solenoid operated with position indicating switch

Solenoid directional valves with switch indicator provide the hydraulic system feedback via an electrical signal indicating whether it is in the open or closed position. This feature is particularly important in applications where personal safety is a priority or where requirements are defined by machinery and safety standards. Monitored valves are commonly used in industries such as steel mills and paper mills, where work and safety cells are present. They enable, for example, clear confirmation that a function is completely shut off during maintenance, or are used as part of safety-critical systems such as emergency shutdown systems.

4 way, 2 position, closed transition, solenoid operated with position indicating switch

Monitored valves with position indicating switch provide reliable feedback via an electrical signal that indicates whether the valve is in the open or closed position. This enhances safety in applications where functional status must be clearly verified, especially in environments where machine and safety standards demand it.

A solenoid directional valve remains in a resting state until activated by an electrical signal. When power is supplied to the valve’s solenoid, a magnetic field is created, which moves the spool (slide) inside the valve. This opens or closes the valve’s ports, depending on the specific function of the valve. When the power is turned off, the spool either returns to its original position using a spring, or by activating an opposite solenoid (depending on the valve’s design).

In environments with strict safety demands—such as heavy industry— monitored valves with position indicating switch are a valuable tool to ensure that all functions operate as intended. We can provide MTTFd values (Mean Time To Dangerous Failure) to support the calculation of Performance Level (PL) in accordance with EN ISO 13849-1, the international standard for safety-related parts of control systems.

The valves are equipped with a PNP solid-state sensor that offers both normally open and normally closed outputs. They come with a 4-pin M12 connector and are rated IP65, ensuring effective protection against dust and water. The valves are CE-approved and factory-set for accurate position indication. Operating voltage: 20–30 VDC.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se