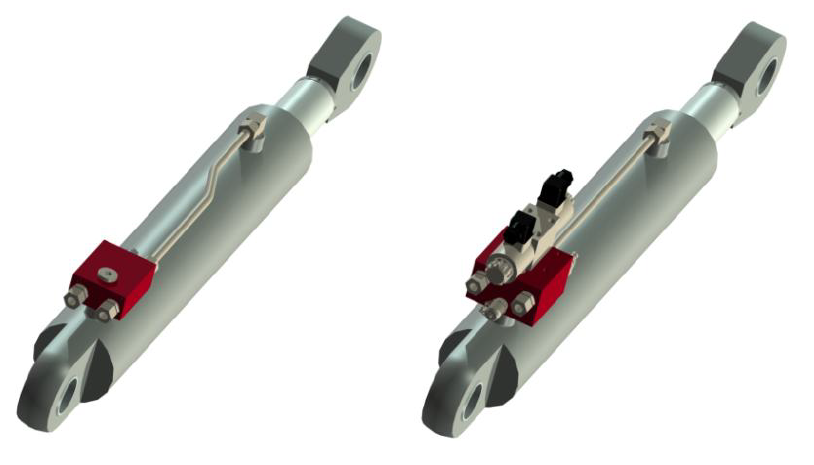

A flow fuse valve, also called hose rupture valve, is used to hold a hydraulic actuator—such as a cylinder or motor—in position in the event of a sudden line break. A line break refers to a failure where a hydraulic hose or pipe bursts, disconnects or cracks, causing hydraulic fluid to rapidly flow from the system. In such a scenario, there is a significant risk that the load may fall uncontrollably or the actuator may move unpredictably, potentially leading to serious personal injury, damage to machinery or other hazardous situations.

The flow fuse valve functions as a safety valve by shutting off the flow when it exceeds a preset threshold—typically triggered by a sudden pressure drop caused by a line break. This prevents the load from falling freely and significantly reduces the risk of accidents.

In many cases, a pilot-operated check valve or a counterbalance valve is used instead of a flow fuse valve, as these often provide higher safety depending on the hydraulic system design. A flow fuse valve is flow-controlled, which means there is always some movement before the valve closes during a sudden increase in flow. In cases of minor leaks, the flow may be too low for the valve to respond, which means the load or actuator risks descending fully. Additionally, flow fuse valves generally result in greater oil leakage compared to pilot-operated check valves or counterbalance valves, which typically offer faster and more controlled shutoff.

Flow fuse valves are especially well suited for applications with single-acting cylinders. In these systems, pilot pressure is often not available, which is required to operate a pilot-operated check valve or a counterbalance valve. Because a flow fuse valve responds to an increase in flow rather than pilot pressure, it becomes an effective alternative to protect the system in the event of a sudden line break. It helps hold the load in position and reduces the risk of uncontrolled movement—even when access to pilot pressure is limited or nonexistent. This makes it particularly useful in simpler or more compact hydraulic systems where safety must still be ensured.

Do you need a flow fuse valve, a pilot-operated check valve or a counterbalance valve? At Hydnet, we are experts in cartridge valves and have extensive experience designing safe and reliable hydraulic systems for a wide range of applications and industries. Contact us—we will help you analyze your system, select the right components, and develop a solution that meets both technical and safety requirements.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se