When designing and constructing a smart hydraulic system, electronic control of functions can be highly beneficial. Electronics are increasingly integrated into modern hydraulic systems, enabling more intelligent and automated solutions. By incorporating electronic feedback of flow, pressure or temperature, hydraulic functions can be precisely monitored and controlled. Contact one of our sales engineers to design your smart hydraulic system.

With feedback from a temperature sensor to a proportional pressure or flow control valve, the fan speed is automatically regulated based on temperature. The fan can also be reversed to clean the filter by blowing it clear.

An accumulator circuit helps maintain the accumulator charge within a desired pressure range. Once the accumulator is fully charged, the pump can be relieved, and the oil is routed directly to the tank. This can result in significant energy savings and reduces unnecessary heat generation in the system.

The XMD control unit uses input from a pressure sensor to monitor the accumulator pressure and regulate a proportional pressure relief valve accordingly.

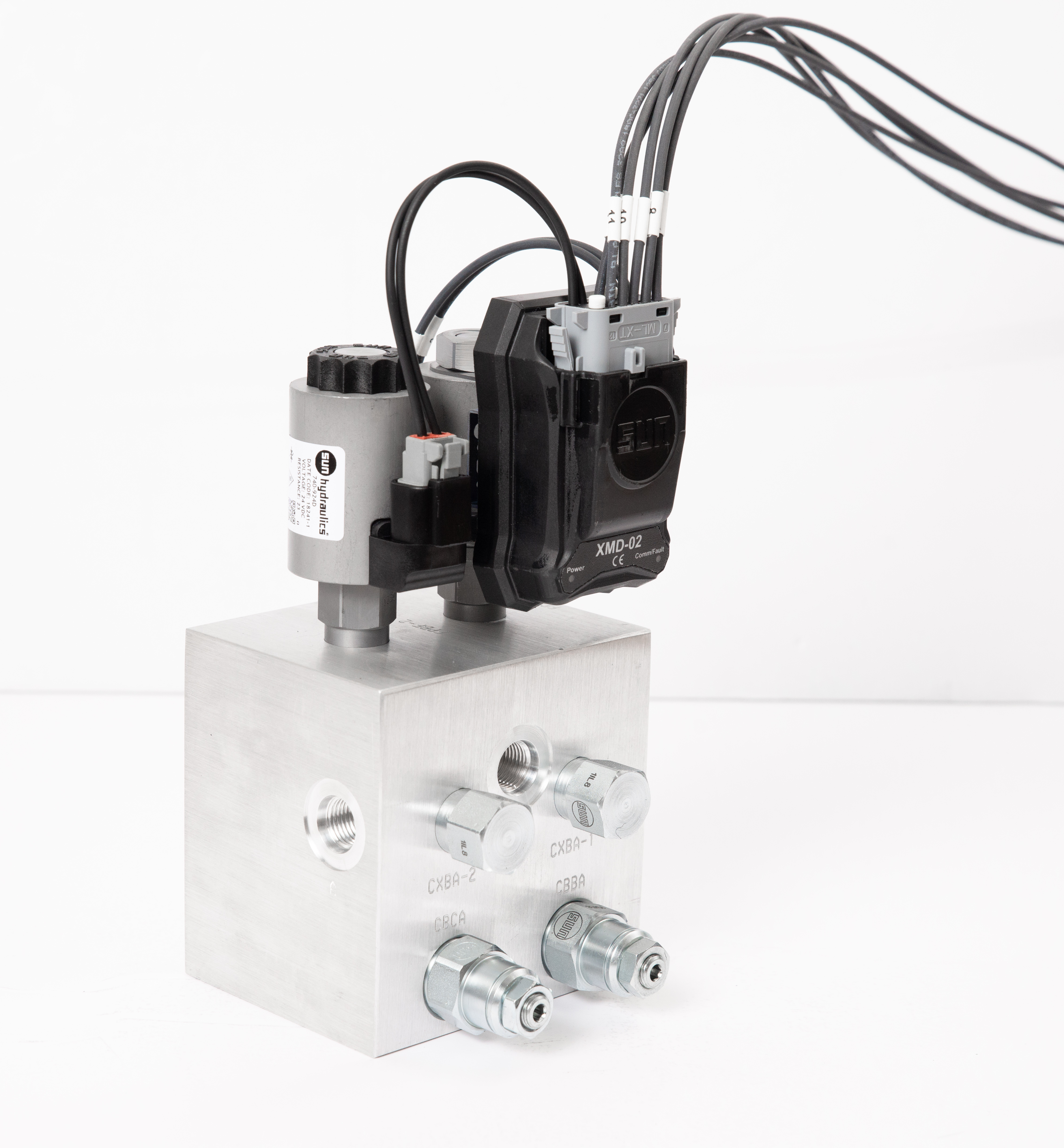

The XMD control unit offers a simple solution for flow regulation. With the XMD-02, for example, proportional flow control can be applied to a hydraulic motor in both directions. Parameter settings for ramping, custom curves, and upper or lower signal thresholds are easily configured and adjusted in the controller.

Sun Hydraulic’s XMD I/O controller allows for easy configuration of parameters such as ramp times, dead man’s grip functionality, PWM, and dither frequencies. Configuration is done via Bluetooth using a smartphone, tablet or PC software. No programming knowledge is required, as the software features an intuitive, user-friendly interface.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se