Sun Hydraulics’ standard range of line mount bodies offers a simple and practical way to add specific functions to a hydraulic system without the need for custom-manufactured components. These bodies are designed for direct installation into hydraulic lines and are available with a wide variety of port configurations to suit different installation needs. A line mount body functions as a compact unit that houses multiple hydraulic functions and valves in a single manifold, connected directly to the piping system. Instead of mounting separate components in various locations, these functions are integrated into one unit, simplifying hose routing, reducing the number of fittings, and minimizing the risk of leakage.

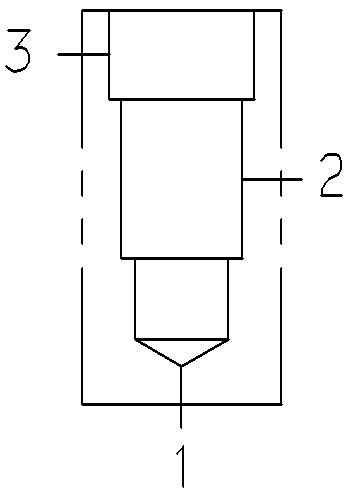

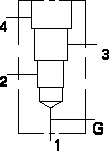

Line mount manifold for counterbalance valves, pilot operated check valves, directional valves and logic elements. 3-ports, 90° body, gauge port.

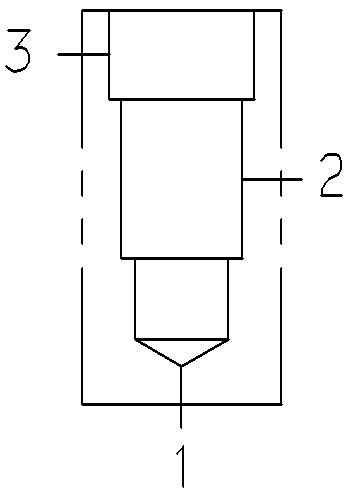

Line mount manifold for directional valves and logic elements. 3-ports, pipe mounted inline body.

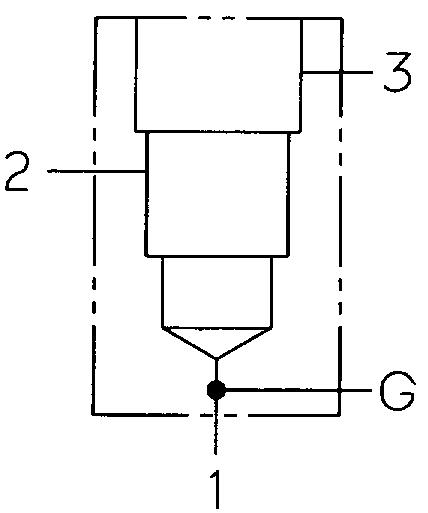

Line mount manifold for counterbalance valves, pilot operated check valves and logic elements. 3-ports, pipe mounted inline body with internal pilot and cavity in C1.

Line mount manifold for counterbalance valves, pilot operated check valves and logic elements. 3-ports, pipe mounted inline body with internal pilot and cavity in C2.

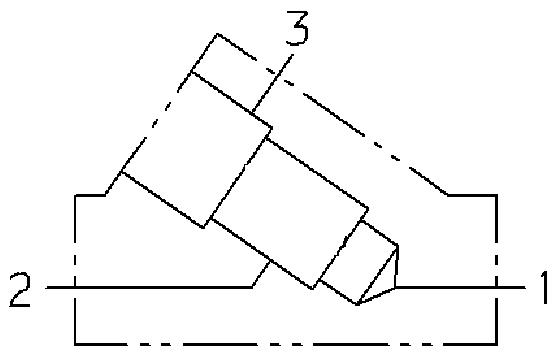

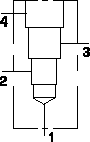

Line mount manifold for counterbalance valves, pilot operated check valves, directional valves and logic elements. 4 ports, 90° body.

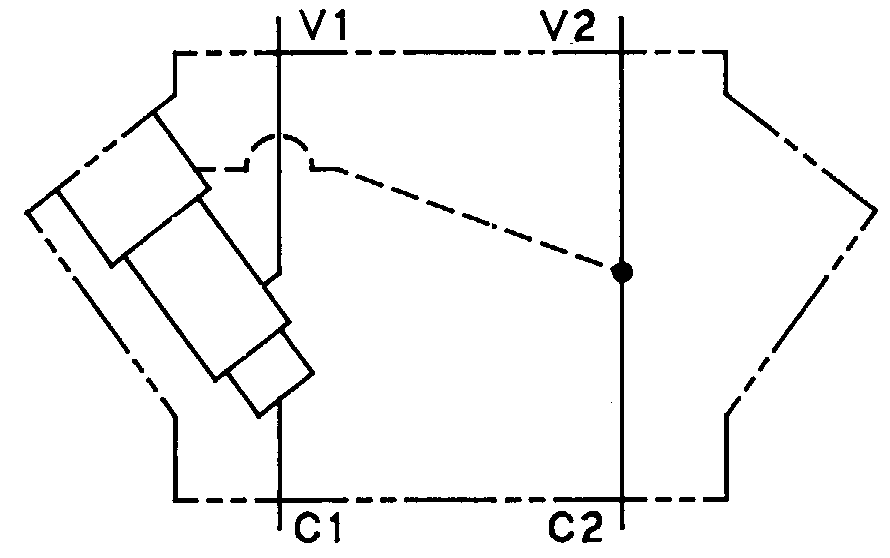

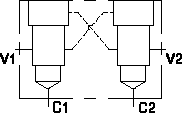

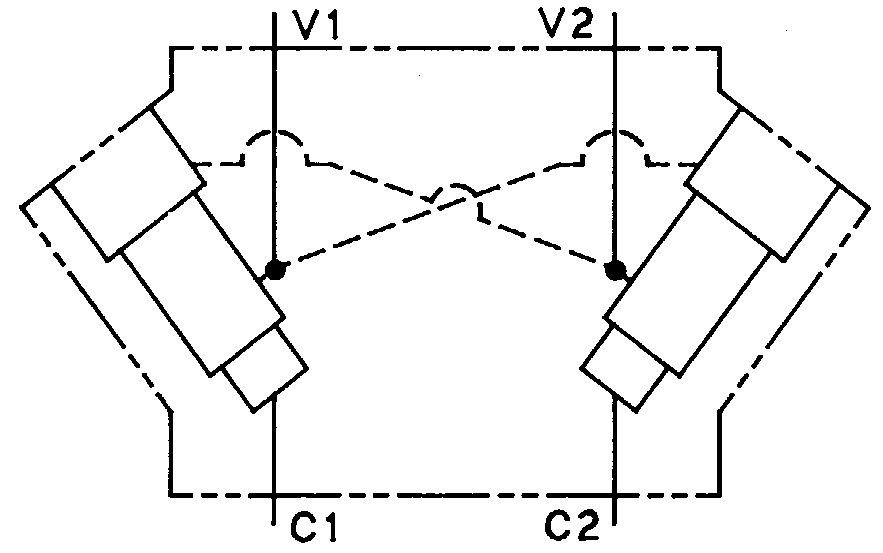

Line mount manifold for counterbalance valves, pilot operated check valves and logic element. Double cavity body with crosspilot.

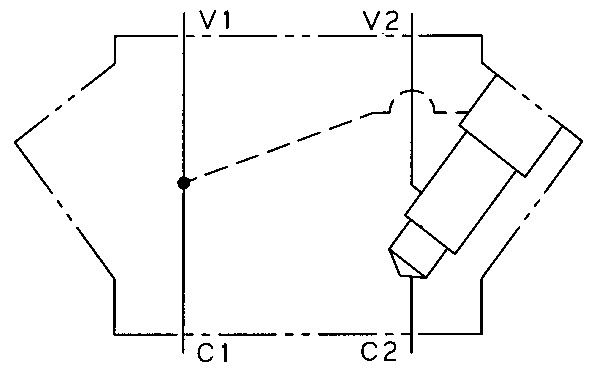

Line mount manifold for counterbalance valves, pilot operated check valvesand logic elements. Double cavity inlinebody with crosspilot.

Line mount manifold for counterbalance valves, pilot operated check valves, directional valves and logic elements. 4-ports, 90° body, gauge port.

Port options

Available port types include NPTF, SAE, BSPP, and Code 61 or Code 62 flanges, making it easy to integrate the body into most hydraulic systems regardless of standard or industry preference.

Sun’s unique cavity system allows a wide range of functions and valve types to be installed in the same cavity. This increases flexibility in system design and allows for faster modifications and simpler replacements without changing the entire body. It also enables customized solutions tailored to specific hydraulic requirements.

Line mount bodies are widely used in mobile and industrial hydraulics where a compact, robust, and service-friendly installation is required. They are ideal in machine construction, construction equipment, and transport applications where vibration resistance and space efficiency are essential. By integrating functions into a single body, assembly is simplified and system performance is optimized.

Sun’s line mount bodies are available in two main materials to suit different pressure ranges and application needs:

• Aluminum: Rated up to 3000 psi (210 bar), ideal for lighter applications where weight and corrosion resistance are priorities

• Steel: Rated up to 5000 psi (350 bar), suitable for more demanding and high-pressure environments

To enhance durability and corrosion protection, several surface treatment options are available:

For aluminum bodies:

• Clear anodize

• Black anodize

For steel bodies:

• Dewatering oil (water-repellent oil)

• Chemical blackening

• Trivalent clear zinc with top sealer

• Clear zinc-nickel with top sealer

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se