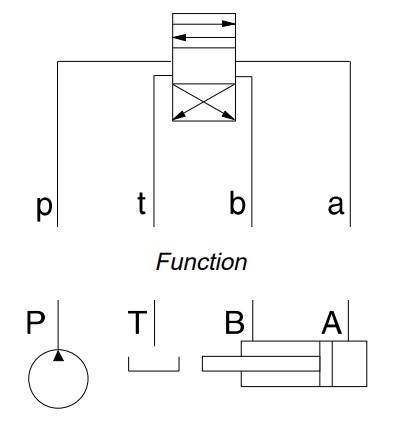

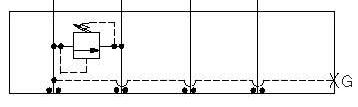

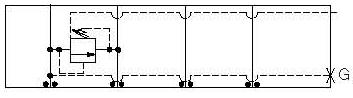

Sandwich manifolds are a smart and simple way to combine multiple hydraulic functions into a compact unit. By stacking the manifolds on top of each other, a modular solution is created that saves space and simplifies installation. Such a stack is often topped with a directional valve, providing a complete and efficient control function in the hydraulic system. To assemble these manifolds, a mounting plate is needed as a base, on which the manifolds are then built up in layers. This design enables customized functionality by combining different valves and manifolds within the same stack, offering high flexibility and easier handling. In a hydraulic schematic, the mounting plate and actuator are typically shown at the bottom, with the directional valve placed at the top of the stack. Below are suggestions for standard valve and manifold combinations, but the system is open to other valves with compatible cavities, allowing solutions to be tailored to specific needs.

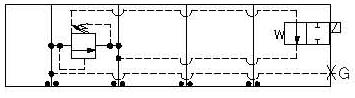

P to T.

P to T, externally vented.

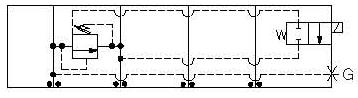

P to T, solenoid operated, normally open.

P to T, solenoid operated, normally closed.

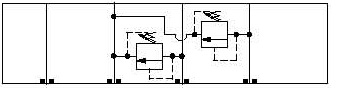

A and B to T.

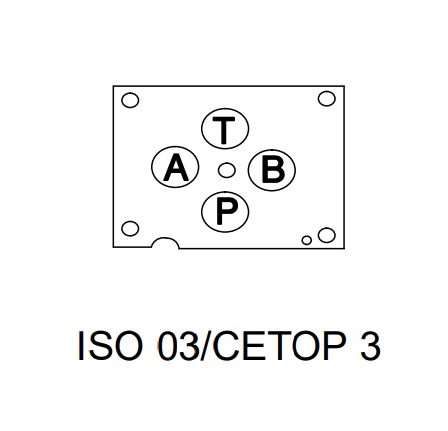

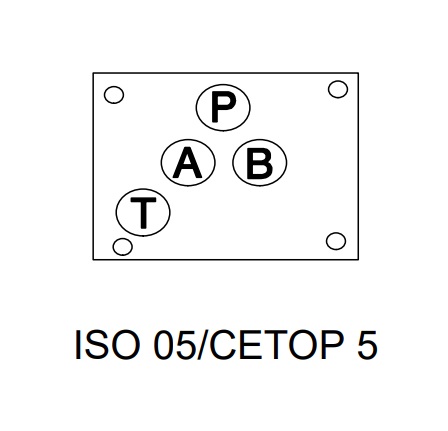

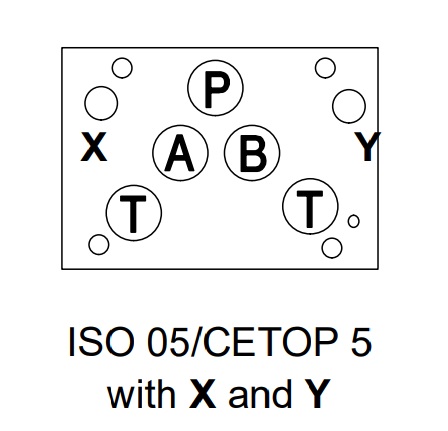

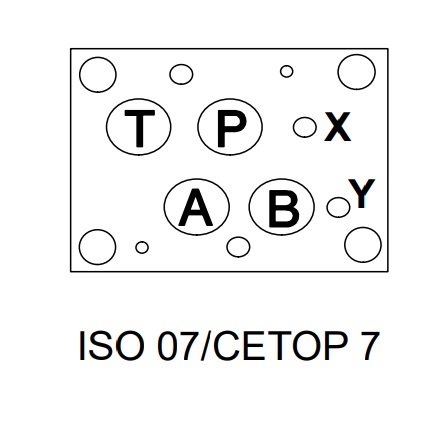

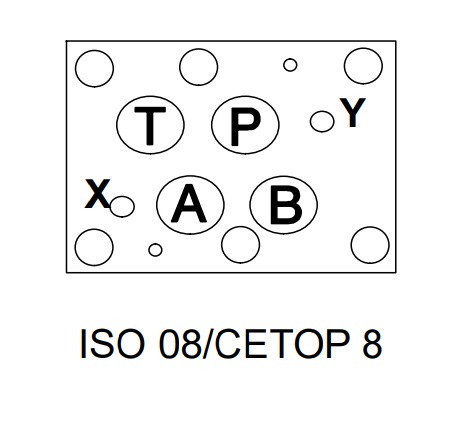

Sandwich manifolds are available in several standard sizes according to ISO/CETOP standards:

• NG4 (ISO/CETOP 02)

• NG6 (ISO/CETOP 03)

• NG10 (ISO/CETOP 05)

• NG16 (ISO/CETOP 07)

• NG25 (ISO/CETOP 08)

• NG32 (ISO/CETOP 10)

These sizes make it easy to combine functions regardless of the application requirements. In addition to standard port patterns, we can also provide custom port patterns, for example for MOOG valves.

Many of Sun Hydraulics’ sandwich manifolds are reversible, meaning the same manifold can be used for several different functions—as long as it is installed in the correct orientation. To fasten the manifolds into a stack, threaded rods and nuts are required, which can be ordered in standard lengths or pre-cut to desired dimensions. This simplifies installation and maintenance.

Sandwich manifolds are available in two main materials to suit different pressure classes and applications:

• Aluminum: For pressures up to 3000 psi (210 bar)

• Steel: For higher pressures, up to 5000 psi (350 bar)

Surface treatments are offered to improve corrosion resistance and durability:

Aluminum manifolds:

• Clear anodize

• Black anodize

Steel manifolds:

• Dewatering oil (water-repellent oil)

• Chemical blackening

• Trivalent clear zinc with top sealer

• Clear zinc-nickel with top sealer

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se