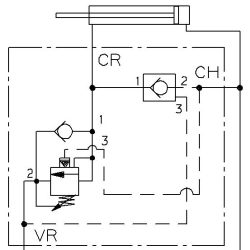

When dealing with a fixed flow rate but wanting to increase the speed of a hydraulic cylinder, regenerative circuits are a common and effective solution.

The principle is to route oil from the rod side (minus side) of the cylinder back to the cap side (plus side). This causes the cylinder to move faster but with reduced force — a function often referred to as rapid advance or fast approach.

In some applications, it is desirable to switch between regenerative and normal operation — for example, in compactors. When the cylinder moves through an unloaded section, the regenerative mode is automatically engaged, allowing the press head to move quickly. Once the press head contacts the material to be compacted and pressure increases, the system switches to normal operation to provide full force. This type of system is called pressure-sensitive.

For applications where automatic switching is not needed, full-time regenerative systems are also available. In such systems, the regenerative function is always active. This allows for the use of a smaller pump, which can offer advantages in terms of installation space, weight, and cost.

Both line-mounted and sandwich-mounted manifold options are available. Line-mounted manifolds come in sizes up to SAE 1 ½” flange, and sandwich-style manifolds are available up to NG25.

Feel free to contact us — we’re happy to help you find the right solution!

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se