Solenoid directional valves are available in corrosion resistant versions – 2-way, 3-way, 4-way and 6-way solenoid directional valves and solenoid directional valves with position switch. Stainless steel cartridge valves are the optimal choice for corrosion-prone environments, such as marine applications, where the risk of rust and material degradation is high. The valves are available either in stainless steel or in standard steel with a zinc-nickel surface treatment that provides effective corrosion protection. SUN Hydraulics stainless steel valves have been salt spray tested for a minimum of 1,000 hours in accordance with quality standards ASTM B117-03 and ISO 9227.

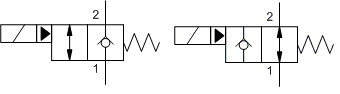

2-way, flow 1 to 2, poppet with 2-stage solenoid operated. Please note that these valves are no longer available. DFCA is replaced by DFCI. DFDA by DFDI. DFEA by DFEI. DFFA by DFFI. For more information, please contact one of our sales engineers.

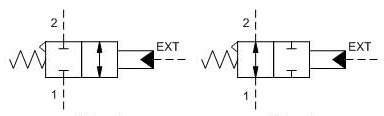

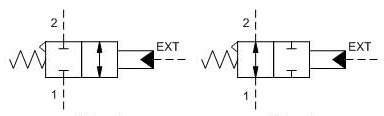

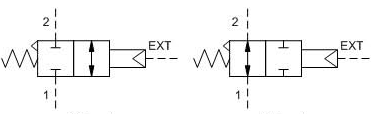

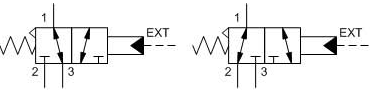

Solenoid directional valves function in the same way as conventional directional valves by controlling the flow of hydraulic oil in a system – but they are activated by an electrical signal instead of manual or pressure control. Electrical signals activate solenoids to move a spool inside the valve, thereby changing the flow paths and controlling the direction of the oil flow in the system.

An electrically controlled directional valve remains in a resting state until activated by an electrical signal. When power is supplied to the valve’s solenoid, a magnetic field is created, which moves the spool (slide) inside the valve. This opens or closes the valve’s ports, depending on the specific function of the valve. When the power is turned off, the spool either returns to its original position using a spring, or by activating an opposite solenoid (depending on the valve’s design).

There is a wide range of solenoids available for solenoid directional valves, with various contact configurations and voltage levels to choose from. Common contact types include Hirschmann and Deutsch, and the solenoids are available for both 12V and 24V. For specific needs, there are also solenoids for alternating current (AC) with built-in rectifiers, as well as ATEX-certified versions for use in explosive environments where special safety requirements apply.

To control the valve function electronically, we offer simple and user-friendly amplifiers and I/O units. This enables smarter and more automated solutions through electronic feedback of parameters such as flow, pressure, or temperature, providing precise control over hydraulic functions. To find the right solution for your system, please contact us — we’ll be happy to assist you.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se