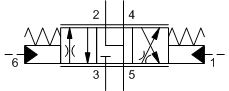

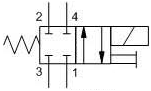

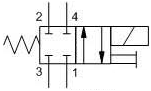

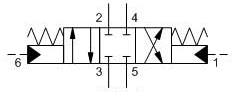

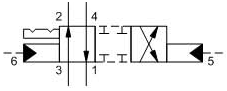

4 ports, 3 position, pilot operated, proportional valve

A 4-way directional valve, also called a 4/2 or 4/3 valve, has four ports and either two or three positions. It is used to control the flow of hydraulic oil in a system through electrical actuation (known as a solenoid valve), manual operation, or pressure changes. The valve’s function is to determine the path the fluid takes — for example, whether it goes to a cylinder to extend it or to another port to retract it. This allows the valve to start, stop, or switch the flow between different functions, making it central to controlling double-acting cylinders and other hydraulic components.

4 ports, 3 position, pilot operated, proportional valve

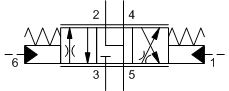

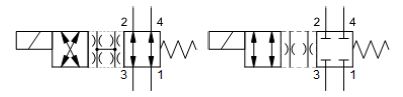

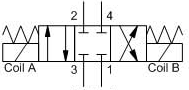

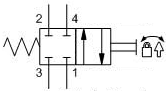

4-way, 2 position

4 way, 2 position, closed transition, solenoid operated with position indicating switch

4-way, direct-acting, balanced piston solenoid-operated directional valve, 3000 psi (210 bar) – common cavity.

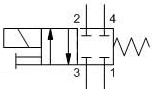

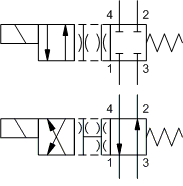

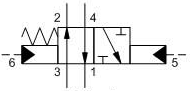

4 way, 2 position, pilot operated

4 way, 3 position, pilot operated

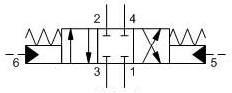

4 way, 2 position, detented, pilot operated

A 4-way directional valve has four ports and either two or three positions. It is commonly used to control double-acting cylinders where the flow can be directed in both directions, and the valve may have a neutral position to stop or allow the flow to circulate. The three positions can, for example, be: one position to extend the cylinder, one position to retract it, and a neutral position where both ports are either closed or connected to the tank to hold the load in position or allow free flow.

4-way directional valves are used in many hydraulic systems where double-acting cylinders are required, such as industrial machinery, lifting equipment, and vehicle applications. They provide precise control of cylinder movements and ensure that the force can be directed and held safely and efficiently. Thanks to the neutral position, the system can be adapted both to lock the position and to reduce energy consumption when movement is not needed.

If there is a need to operate the directional valve manually – for example during maintenance, troubleshooting, or in emergency situations – the valve can be equipped with a manual override. These are available in two versions: with a maintained position, where the valve stays in the manual position until changed again, or with a spring-return position, where the valve automatically returns to its original state once the manual operation is released.

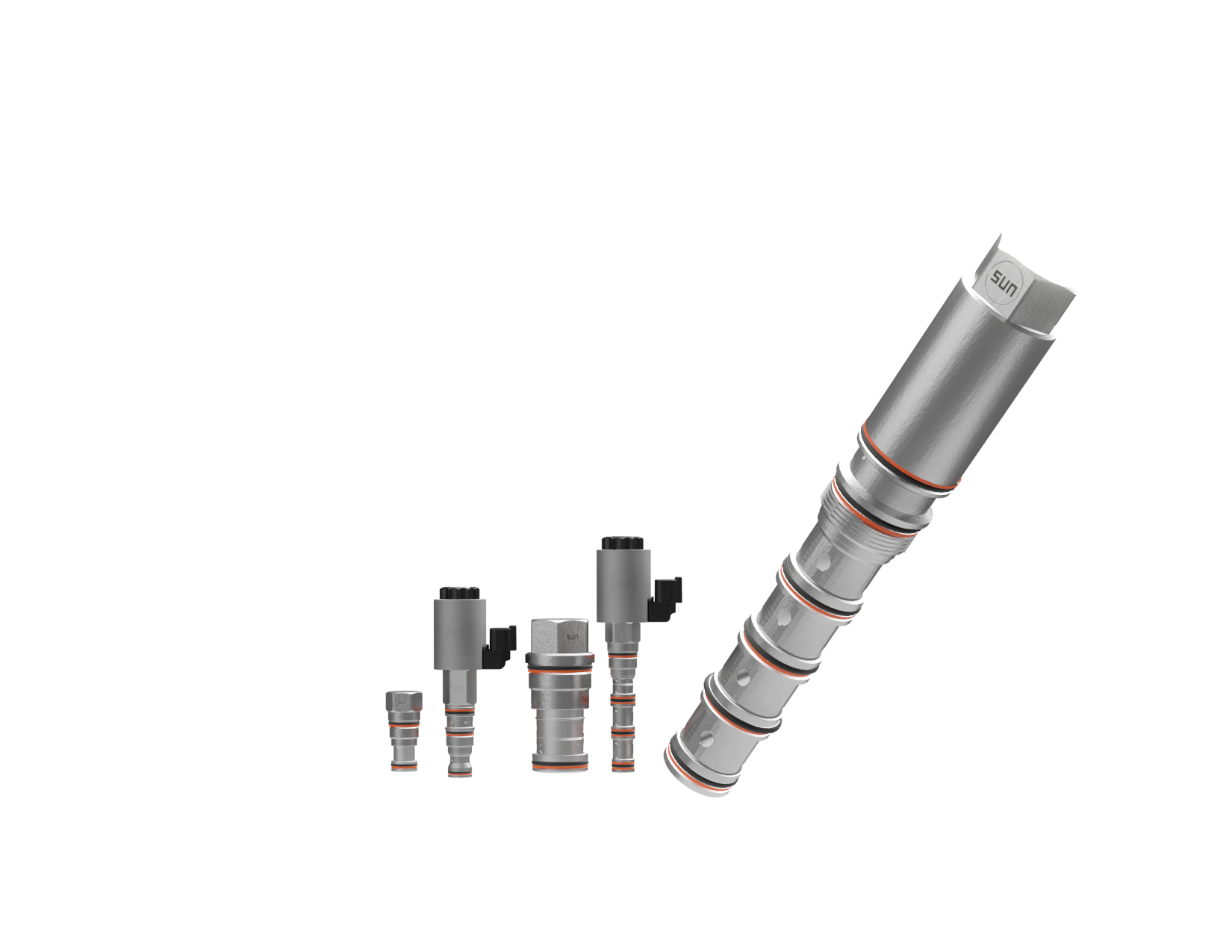

Hydnet holds the largest stock of Sun Hydraulics cartridge valves in Europe, enabling immediate delivery – in urgent cases, we can often deliver the same day. When you choose Sun Hydraulics, you can be completely confident in your decision. Each cartridge valve is manufactured to the highest quality standards and undergoes thorough testing, with every unit tested individually before it leaves the factory. This ensures outstanding performance and maximum operational reliability.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se