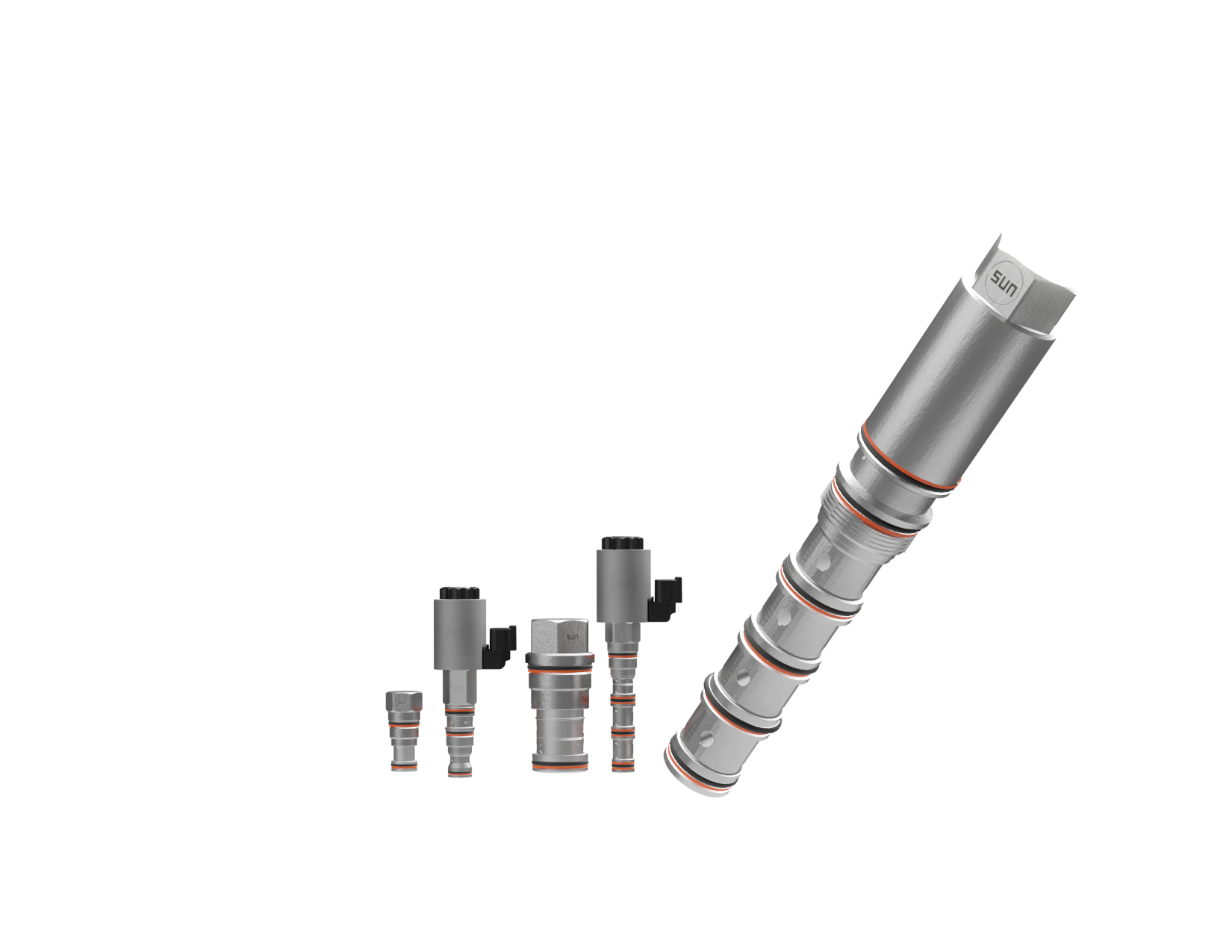

Single ball, signal external, 2 ports

Shuttle valves are directional valves controlled by pressure differences in a hydraulic system. The valves have two, three or four separate inlets and a common outlet, and it automatically connects the inlet with the highest pressure to the outlet. This way, the valve allows flow from multiple pressure sources but only permits the flow from the source with the highest pressure to pass through to the outlet.

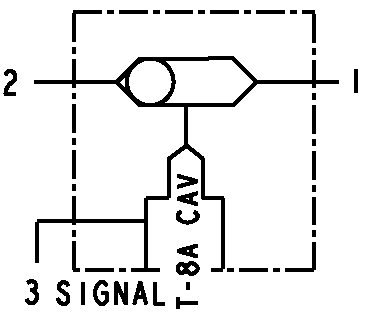

Single ball, signal external, 2 ports

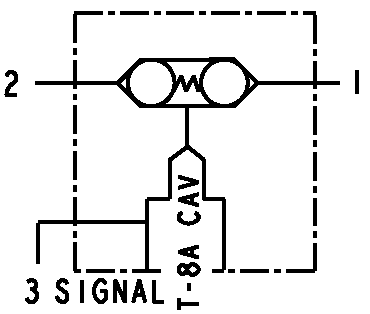

Single ball, signal at port 2, 2 ports

Insert style, single ball shuttle valve with signal external, 2 ports

Insert style, single ball shuttle valve with signal at port 2, 2 ports

Insert style, single ball shuttle valve with signal at port 2, 2 ports

Single ball, signal at port 3, 3 ports

Single ball, signal at port 2, 3 ports

Single ball, signal at port 3 and T-8A in hexbody, 3 ports

Back-to-back signal at port 3 and T-8A in hexbody, 3 ports

Low side (hot oil), 3 position, 4 ports

Low side (hot oil), delay shift, 3 position, 4 ports

High side, 3 position, 4 ports

High side, spring offset, 4 ports

Inside a shuttle valve, there is a movable check ball or spool that is automatically pushed aside by the highest incoming pressure. This movement blocks one inlet port and opens the other, allowing the flow from the port with the highest pressure to pass through. The shuttle valve thus acts as an automatic switch that always lets the dominant pressure continue through the system, for example, to a control signal or a braking system.

Shuttle valves are often used to take control pressure from the line currently having the highest pressure. This is common in load-sensing systems where the pump pressure setting is controlled by the function requiring the most pressure. For this purpose, multiple shuttle valves are usually connected in series. Another common application is in hydraulic systems with braking functions, where a hydraulic motor is equipped with a brake that releases under pressure. The shuttle valve then ensures that the brake remains open regardless of which side of the motor is pressurized, enhancing both safety and operational reliability of the system.

Shuttle valves also come in a variant called a “low side shuttle,” where the side with the lowest pressure is automatically connected to the outlet. In this design, the port with higher pressure is blocked, and the oil from the low-pressure side is directed onward. This type of valve is often used in transmission circuits—such as in hydrostatic drive systems—where it is important to divert warm oil from the low-pressure side for cooling and filtration before it is returned to the system. By using a low side shuttle, it is ensured that oil is always taken from the side of the transmission that is not pressurized, improving cooling, cleaning and the lifespan of the system components.

Shuttle valves are simple and reliable, making them highly valued in hydraulic systems where safety and quick response are critical. Their ability to automatically select the highest pressure source contributes to more efficient system operation and protects components from pressure drops or incorrect control.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se