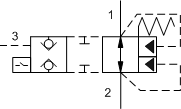

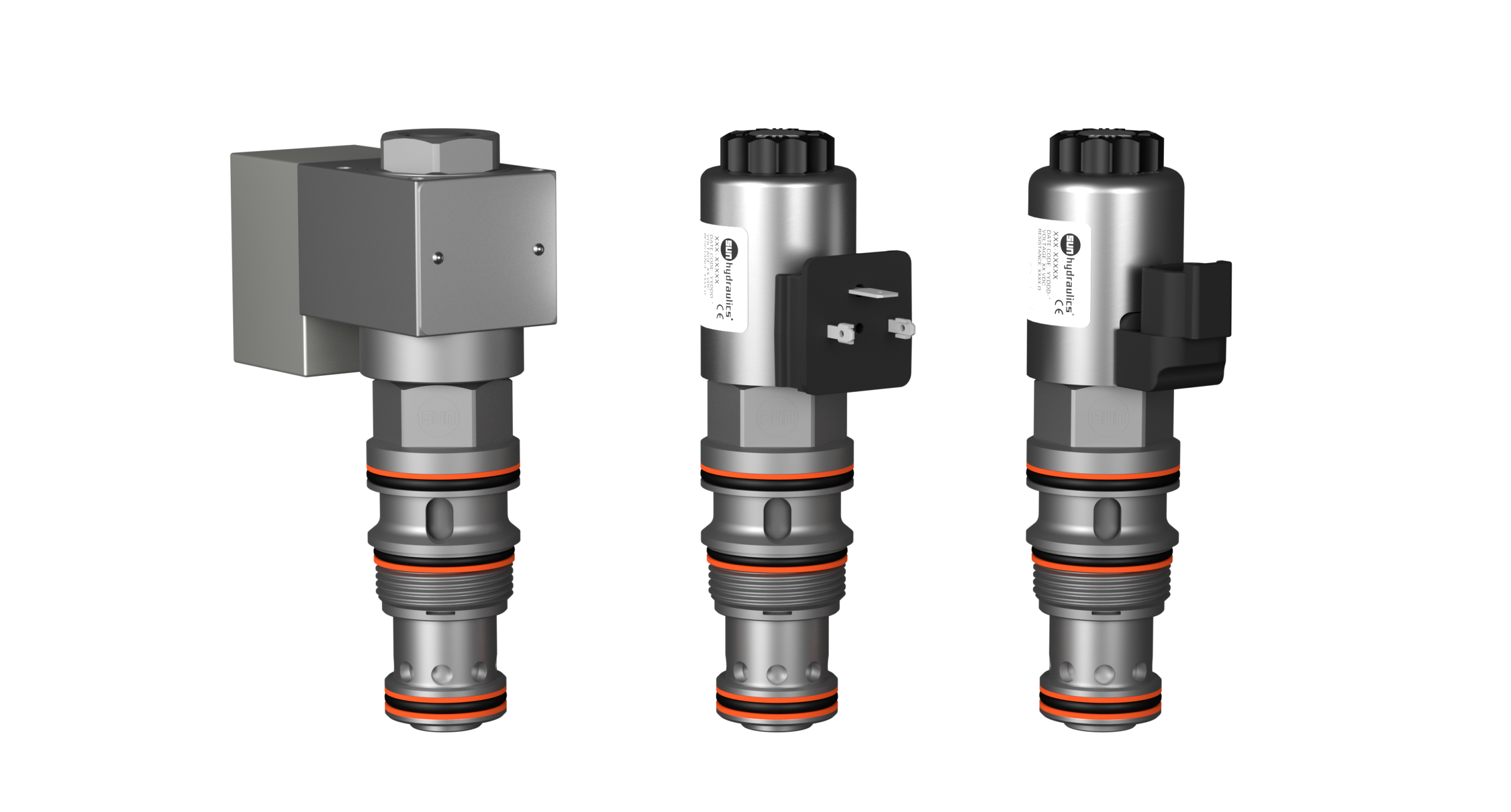

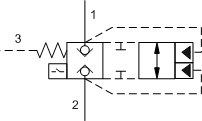

Pilot-to-close, spring biased open with position indicating switch, unbalanced poppet

A logic element (logic valve) is a type of valve used to control flow or pressure based on certain logical conditions – “if this happens, then do that.” It functions similarly to a logic gate, where a control signal determines how the logic element will respond. Logic elements are often used to build hydraulic control logic without electronics, making the systems robust and reliable, even in demanding environments. These valves can be used in a wide range of hydraulic systems and when combined with other valves, can create functions for directional, flow and pressure control. Logic elements with position switch provide feedback via an electrical signal that indicates whether the valve is in the open or closed position.

Pilot-to-close, spring biased open with position indicating switch, unbalanced poppet

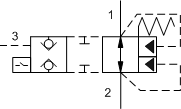

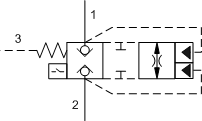

Pilot-to-open, spring biased closed with position indicating switch, unbalanced poppet

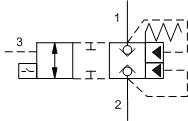

Pilot-to-close, spring biased closed with position indicating switch, unbalanced poppet

Pilot-to-close, spring biased closed with metering notches and position indicating switch, unbalanced poppet

Logic elements with position switch provide feedback via an electrical signal indicating whether the valve is in the open or closed position. These are often used in applications where personal safety is critical or where machine and safety standards require it.

You can always feel confident when choosing Sun Hydraulics cartridge valves. Their products are manufactured to the highest quality standards, and to ensure performance and reliability, each cartridge valve is individually tested before leaving the factory.

Logic elements with position switch are common in industrial sectors such as steel mills and paper mills, where work and safety cells are part of the process environment. The electrical feedback enables, for example, confirmation that a function is completely shut off during maintenance or that a safety-critical system, such as an emergency stop, has been correctly activated. We can provide MTTFd values (Mean Time To Dangerous Failure) for calculating Performance Level (PL) according to EN ISO 13849-1 – the international safety standard for machinery: Safety-related parts of control systems.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se