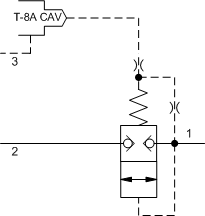

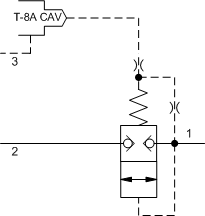

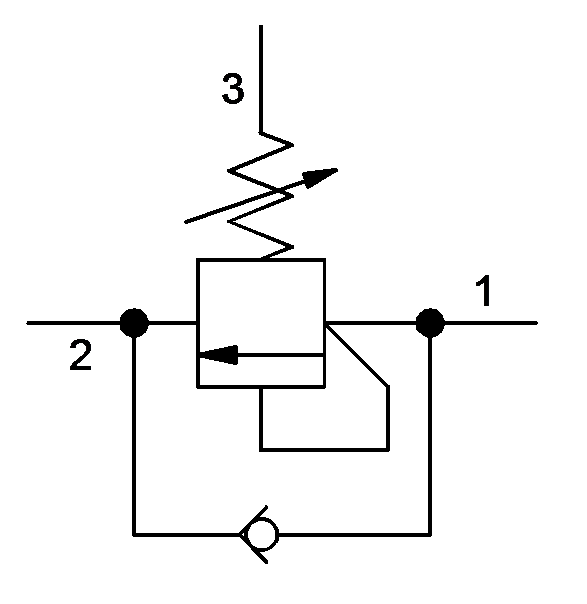

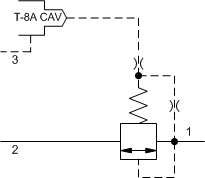

3 ports, pilot operated, balanced poppet sequence main stage with integral T-8A control cavity

A sequence valve is a control valve used in hydraulic systems to determine the order in which various functions are activated, based on pressure levels. It ensures that one operation is initiated only after a specific pressure is reached in another part of the system. The sequence valve remains closed under normal conditions and opens only when the pressure reaches a preset value. A common application is with two hydraulic cylinders, where “cylinder two” starts moving only after “cylinder one” is fully extended. Sequence valves are typically used in systems such as lifting equipment, presses, hydraulic grippers, and sequential hatch control.

3 ports, pilot operated, balanced poppet sequence main stage with integral T-8A control cavity

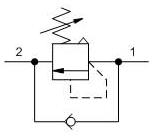

2 ports, atmospherically referenced, direct acting without reverse flow check

2 ports, atmospherically referenced, direct acting with reverse flow check

3 ports, pilot operated, balanced poppet

3 ports, direct acting with reverse flow check

3 ports, direct acting without reverse flow check

3 ports, pilot operated, balanced piston, air controlled

3 ports, pilot operated, balanced piston sequence main stage with integral T-8A control cavity

Sequence valves are common components in the manufacturing industry, for example in sawmills and steelworks. A typical use case is to ensure that a clamping or fastening function is fully activated before the next step in the process, such as cutting, bending, or drilling is initiated. Another example is a machine with safety covers, where a first cylinder is used to close the safety cover, and a sequence valve ensures that the cover is fully closed before a second cylinder is allowed to be activated.

Sequence valves are available in five different sizes, offering flows of up to 480 l/min. They are functionally interchangeable with each other, and within the same flow range, they have the same cavity. The valves are also fully adjustable over a wide pressure regulation range, with a pressure of up to 350 bar, and intermittent operation up to 420 bar (excluding air-piloted valves).

Sequence cartridges are similar to relief cartridges except the pilot is separately drained so that valve setting is not affected by pressure in the outlet port. When the sequence valve reaches the preset opening pressure, it allows the flow to pass to the next function in the system. Since the spring chamber has a separate drainage, the valve’s function is not affected by any backpressure downstream. To allow for return flow, a check valve is required. Sun Hydraulics offers several combination valves that integrate both sequence and check valve functions – these are identified by the designation SC** in the product code.

Sequence valves are often integrated into line mount bodies or sandwich manifolds for compact and modular construction. They can also be combined with solenoids for electrical control of the sequence function. Regardless of your system configuration, we can help you find the right solution – contact one of our sales engineers, and we’ll guide you through the entire process.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se