Some of Sun Hydraulics specialty valves are available as corrosion resistant – cavity plugs, cavity adaptors and circuit savers. Stainless steel parts are the optimal choice for corrosion-prone environments, such as marine applications, where the risk of rust and material degradation is high. The valves are available either in stainless steel or in standard steel with a zinc-nickel surface treatment that provides effective corrosion protection. SUN Hydraulics stainless steel valves have been salt spray tested for a minimum of 1,000 hours in accordance with quality standards ASTM B117-03 and ISO 9227.

2 ports, port 1 open to external port, port 2 blocked

2 ports, port 2 open to external port, port 1 blocked

3 ports, pilot to close check valve, 20:1 pilot ratio

3 ports, port 1 open to external port, ports 2 and 3 blocked

3 ports, ports 1 to 2 open, port 3 blocked

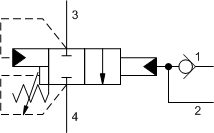

4 ports, accumulator sense, pump unload, pilot valve, with check

3 ports, ports 1 to 3 open, port 2 blocked

3 ports, ports 2 to 3 open, port 1 blocked

4 ports, all ports blocked

4 ports, all ports blocked

4 ports, ports 1 to 2 open, ports 3 and 4 blocked

4 ports, ports 1 to 3 open, ports 2 and 4 blocked

6 ports, all ports blocked

6 ports, ports 1, 2, 3 and 4 open, ports 5 and 6 blocked

Stainless steel cartridge valves are ideal for use in environments exposed to aggressive substances such as salt, chemicals, agricultural fertilizers or chlorine. These valves are particularly well-suited for applications where corrosion resistance is critical, such as marine environments (e.g. offshore platforms), the chemical industry, agricultural machinery, water treatment and wastewater systems. They are also suitable for equipment exposed to year-round weather conditions, where moisture, rain, and temperature fluctuations can lead to rust. Examples of such applications include snow cannons, port equipment and mobile hydraulic systems.

In processes where both hygiene and corrosion resistance are essential—such as in the food and beverage industry (including dairies, breweries, and meat processing)—stainless steel valves are used to prevent contamination and meet strict hygiene standards. This type of valve ensures long-term operation without compromising product cleanliness or safety.

Sun Hydraulics offers two options for achieving corrosion-protected cartridge valves. The first option is a valve with external components made of lean duplex stainless steel, which provides an optimal balance between corrosion resistance and mechanical strength. The adjustment screws are made of either titanium or silicon brass. To ensure high corrosion resistance, the valves have been tested in a salt spray for 1,000 hours in accordance with ASTM B117 and ISO 9227. These valves are particularly suitable for applications in highly corrosive or demanding environments where maximum resistance and longevity are required.

The second option is a valve made from standard steel that has been plated with a zinc-nickel finish. The coating is applied to all external steel parts of the valve and meets the requirements of the SAE AMS 2417 standard. To ensure high corrosion resistance, the valves have been tested in a salt spray for 1,000 hours in accordance with ASTM B117 and ISO 9227. These valves provide strong protection against corrosion and is a cost-effective alternative for less demanding environments.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se