Check valves are one of the most common types of directional valves and allow free flow in one direction while completely blocking flow in the opposite direction. They are used to prevent backflow and ensure that the hydraulic oil moves in only one direction within the system. The function of a check valve is to permit flow in the desired direction and stop flow in the reverse direction, protecting components and maintaining system pressure and operation.

3 ports, pilot to close check valve with bypass orifice

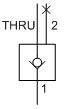

2 ports, free flow nose to side

2 ports, free flow nose to side piston type for hot oil checkvalve

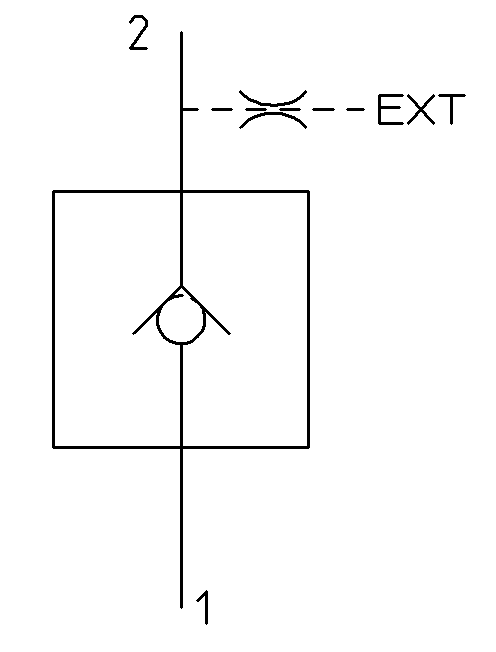

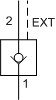

2 ports, free flow side to nose check with auxillary external port

2 ports, free flow nose to side check with auxillary external port

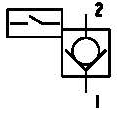

2 ports, mechanically-operated back to back check valve, double acting

2 ports, free flow nose to side with position indication switch, excellent as flow indicator

3 ports, free flow nose to side, port 3 blocked

3 ports, free flow side to nose, port 3 blocked

3 ports, bypass orifice, free flow side to nose, port 3 blocked

Check valves are one of the most common types of hydraulic valves and are found in almost every hydraulic system. They allow free flow in one direction but completely block flow in the opposite direction, preventing unwanted backflow. Their simple design and reliable operation make them very robust and dependable, which is why they are so highly valued. Check valves are often placed directly after a pump to prevent backflow into the pump or to maintain pressure in a specific part of the system when other sections are shut off.

A check valve typically consists of a ball or cone pressed against the valve seat by a spring, which keeps the valve closed. When the flow pressure overcomes the spring force, the valve opens and allows flow in the correct direction. Mechanical check valves are often used in cylinders connected in parallel to synchronize their movements. If one cylinder reaches its end position before another, the check valve opens to allow flow so the other cylinder can complete its movement.

Check valves are used, among other things, in lift tables, elevators, and other lifting devices where they lock the load in a raised position. Lowering is controlled by another valve, often an on/off solenoid valve. They also function as cavitation protection in hydraulic motors by helping to refill oil on the inlet side during rapid stops. Thanks to their function, check valves are found in many applications where safety and reliability are critical.

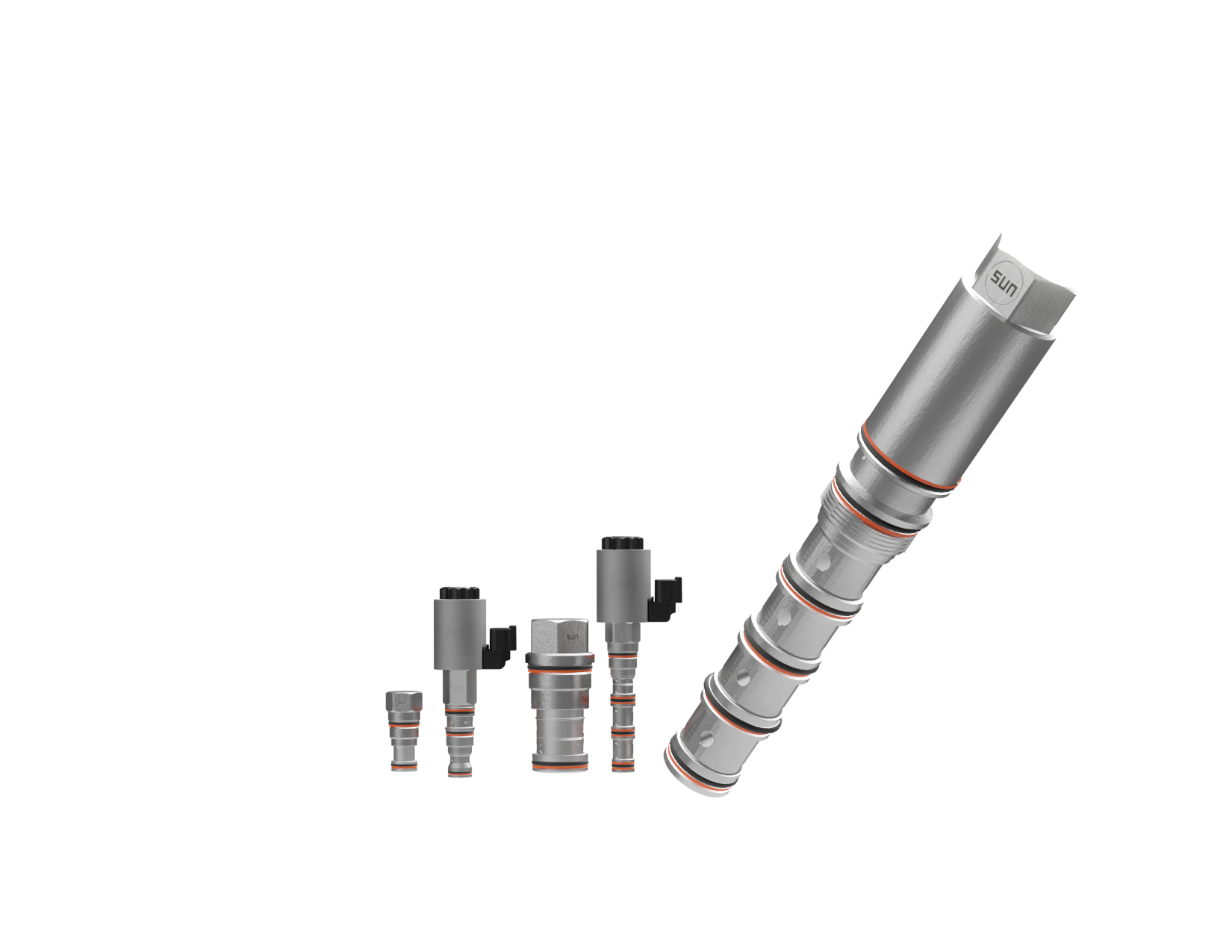

Sun Hydraulics check valves combine high flow capacity with a compact design. The valve’s main port is designated as port 1 and the side port as port 2. The valve is available for flow from port 1 to port 2 or in the opposite direction from port 2 to port 1. There are also three-port models where port 3 is blocked, used in regenerative circuits. Pilot-operated check valves, known as “pilot to close,” are used, for example, in accumulator dump functions. Sun Hydraulics check valves handle pressures up to 350 bar and flow rates up to 600 l/min.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se