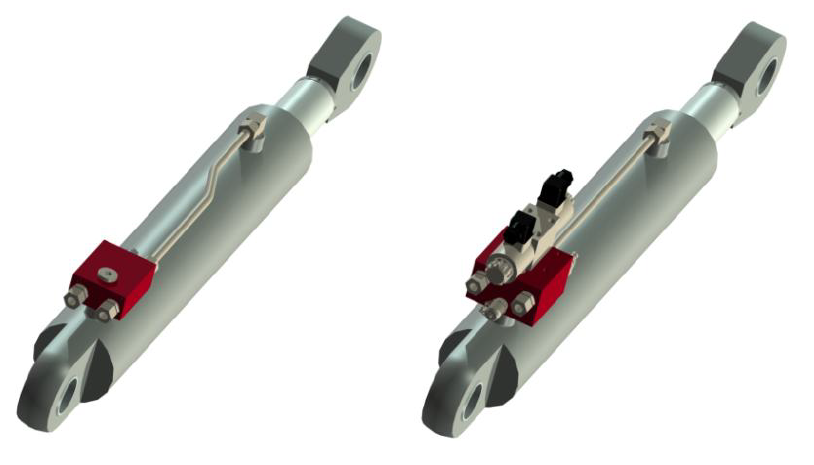

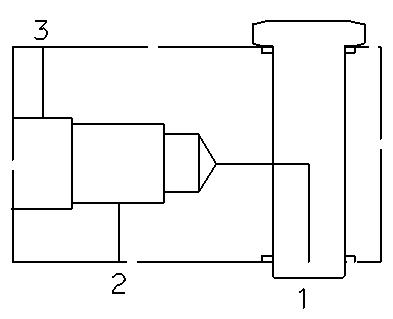

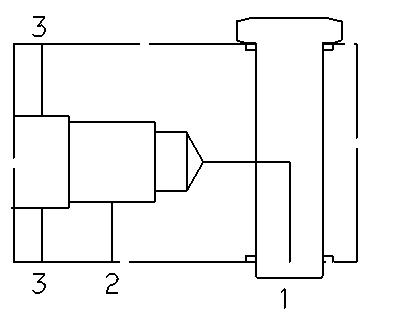

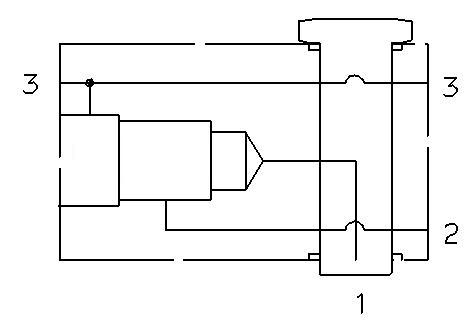

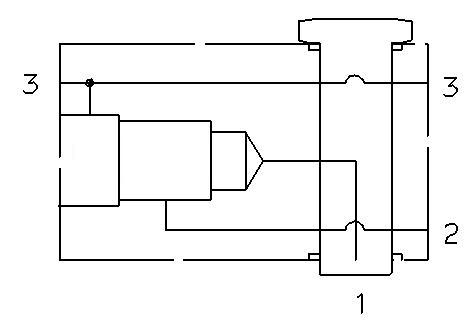

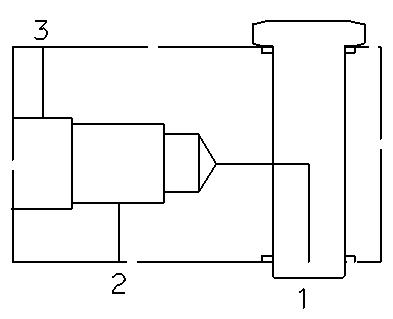

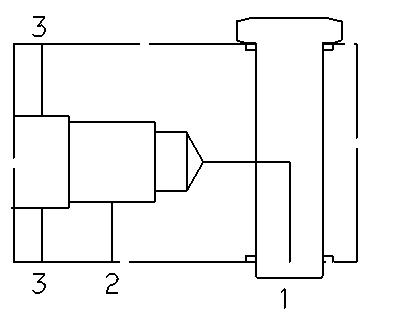

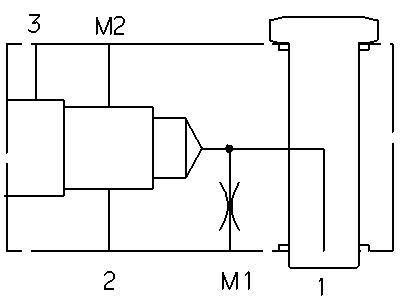

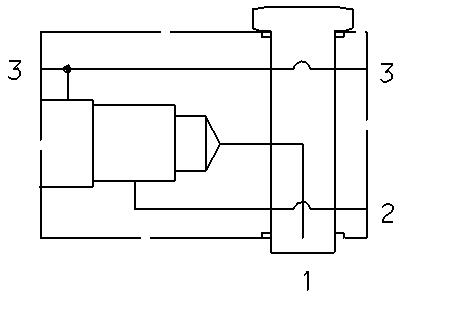

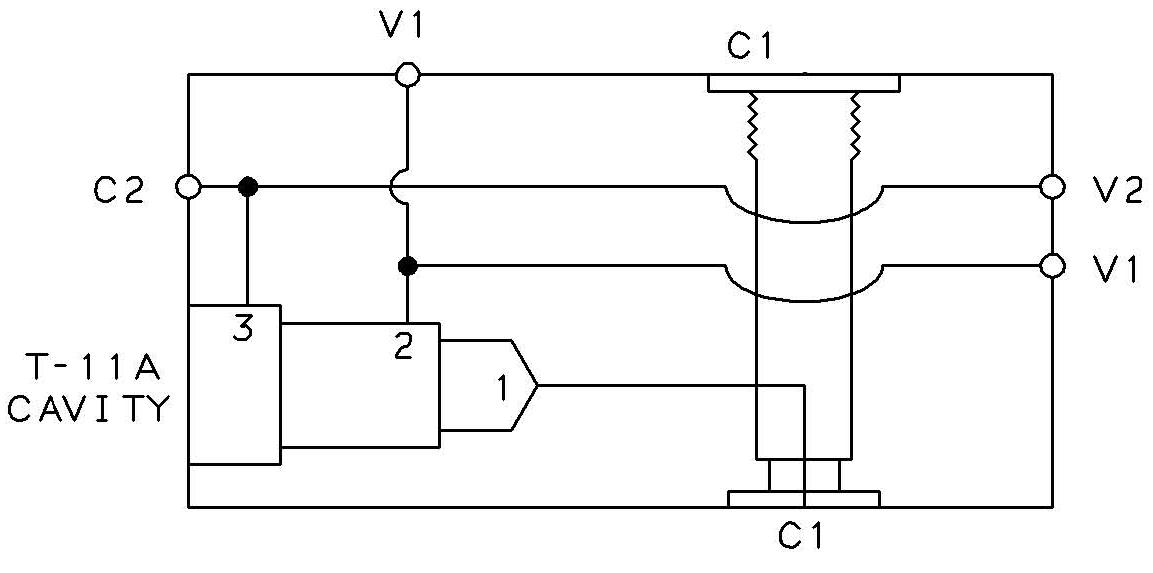

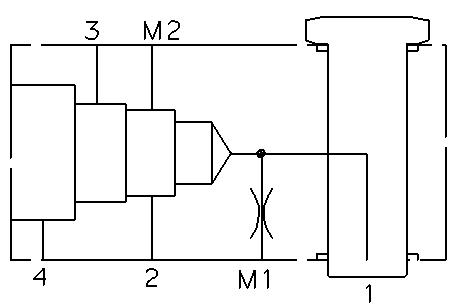

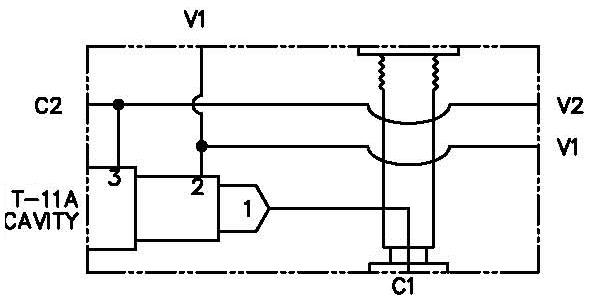

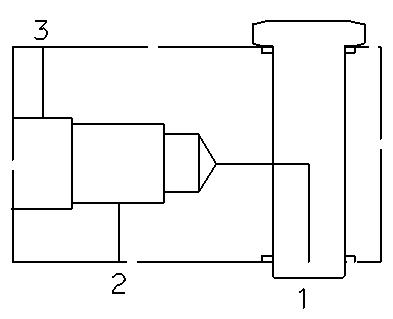

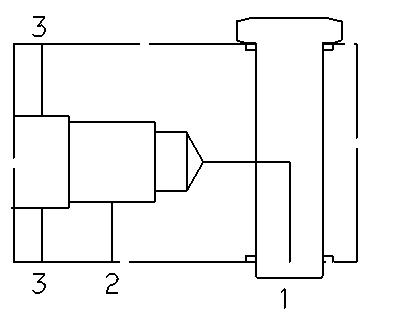

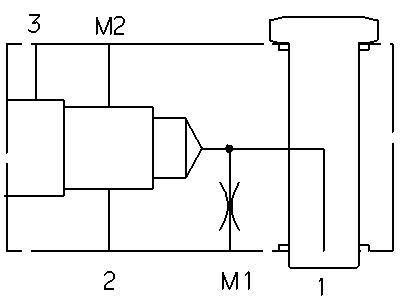

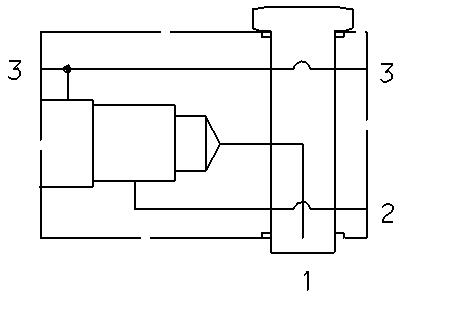

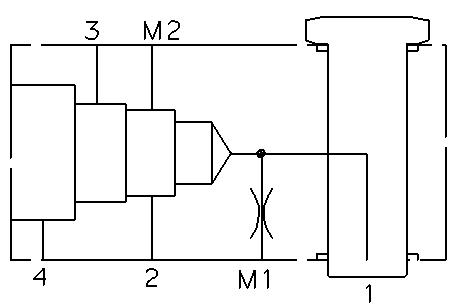

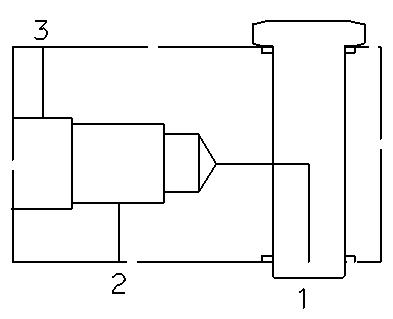

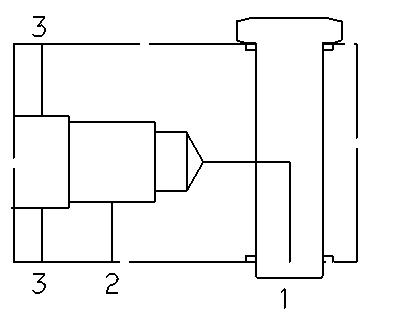

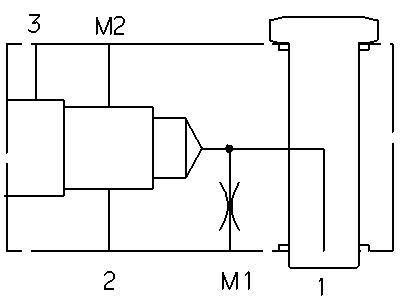

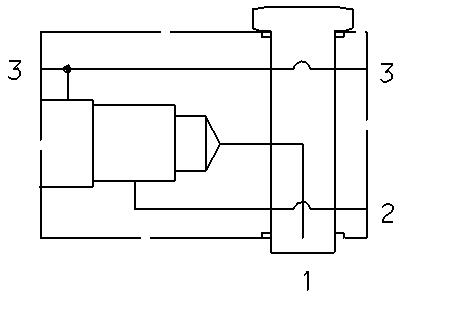

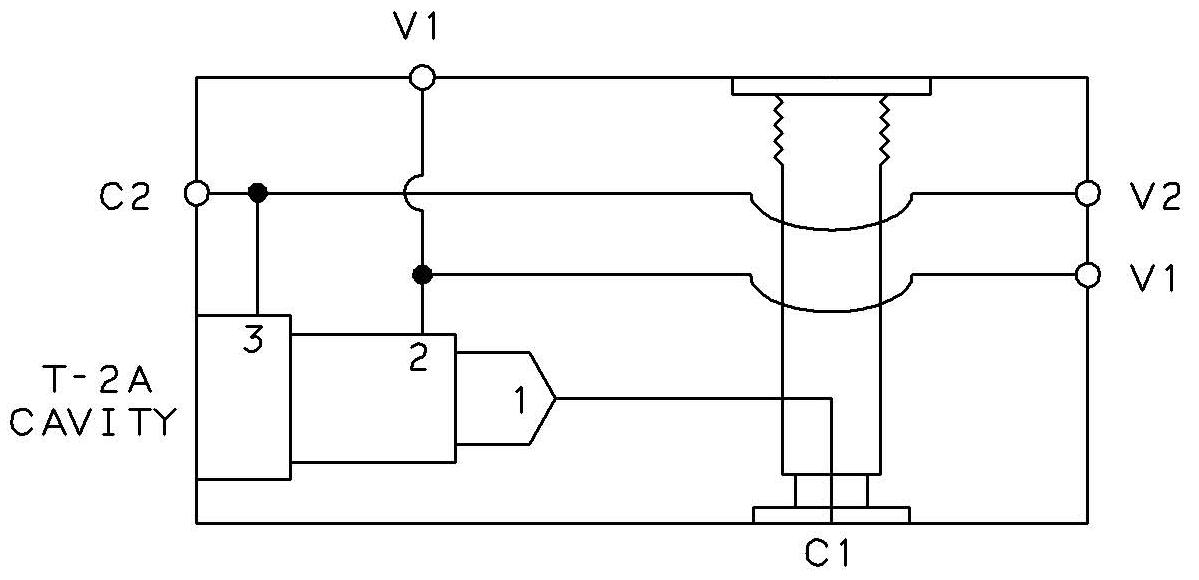

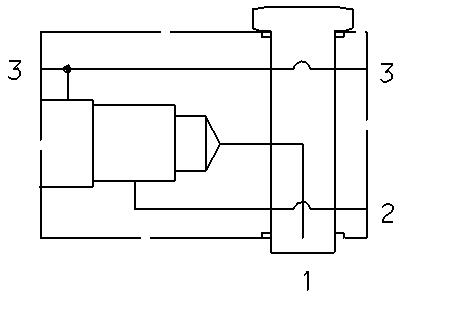

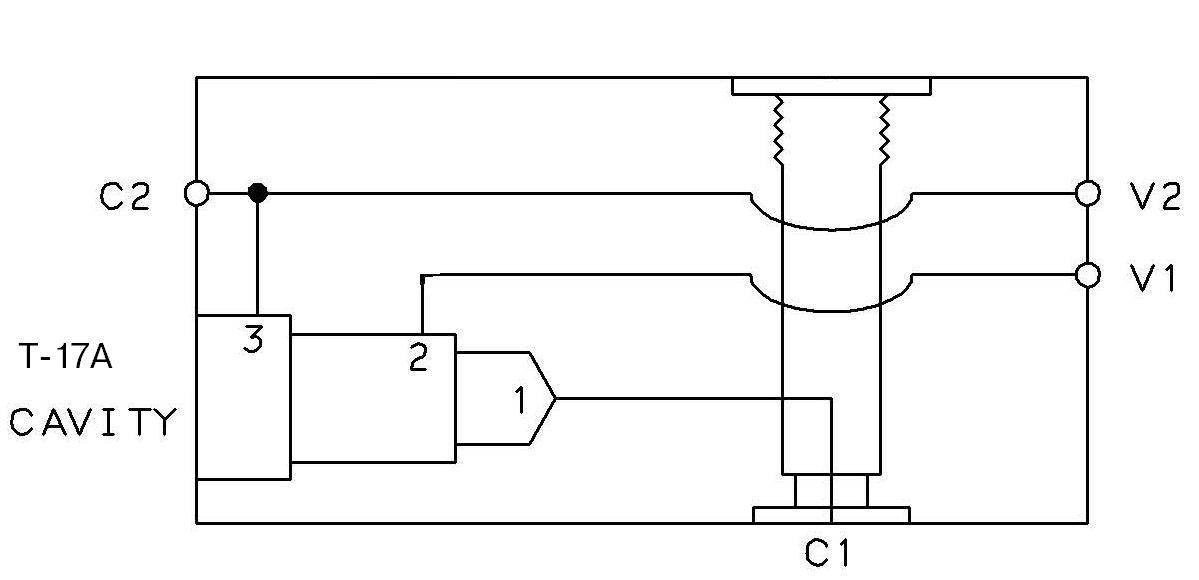

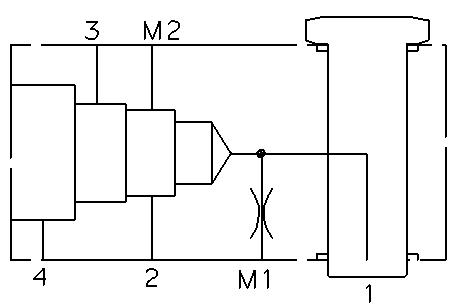

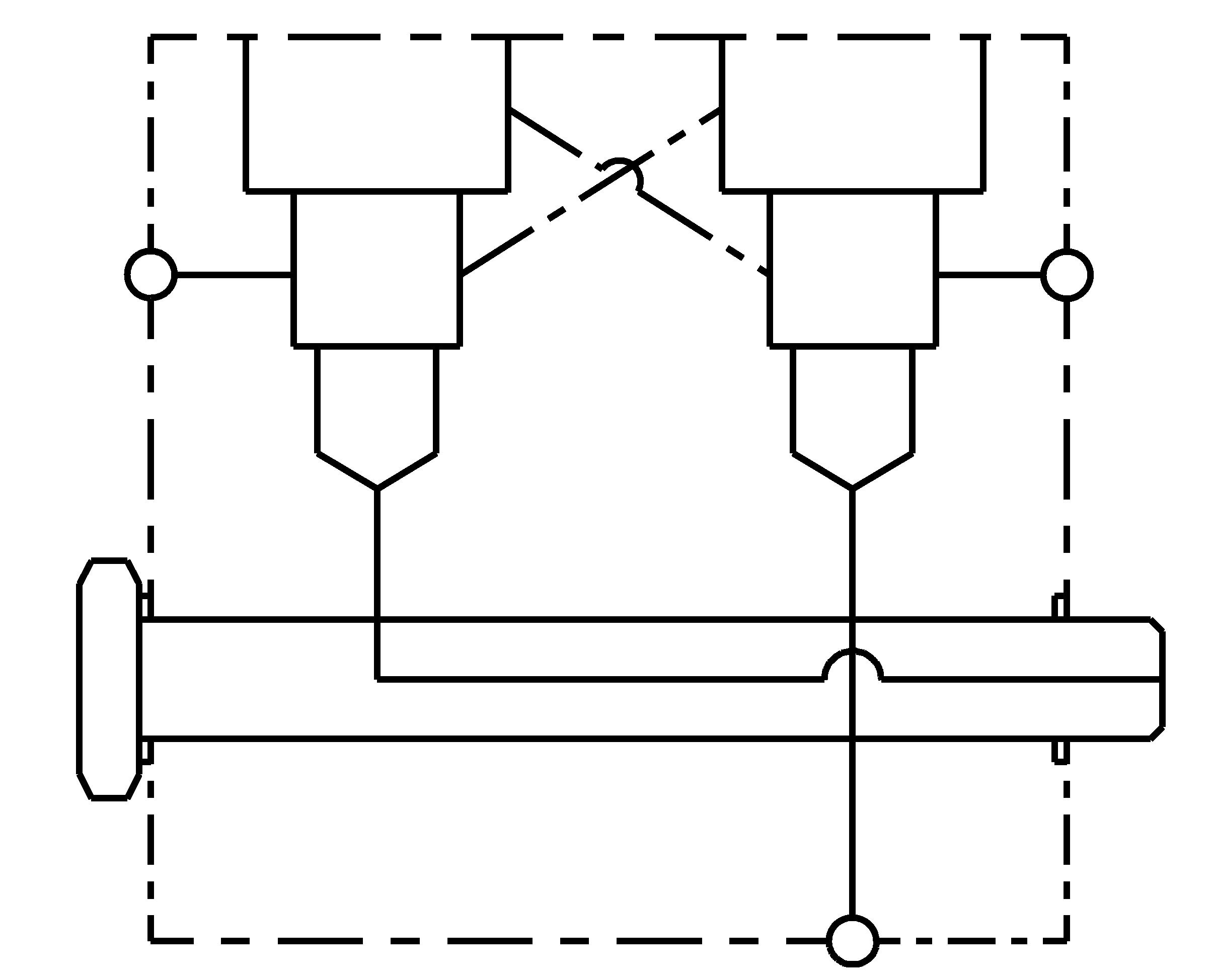

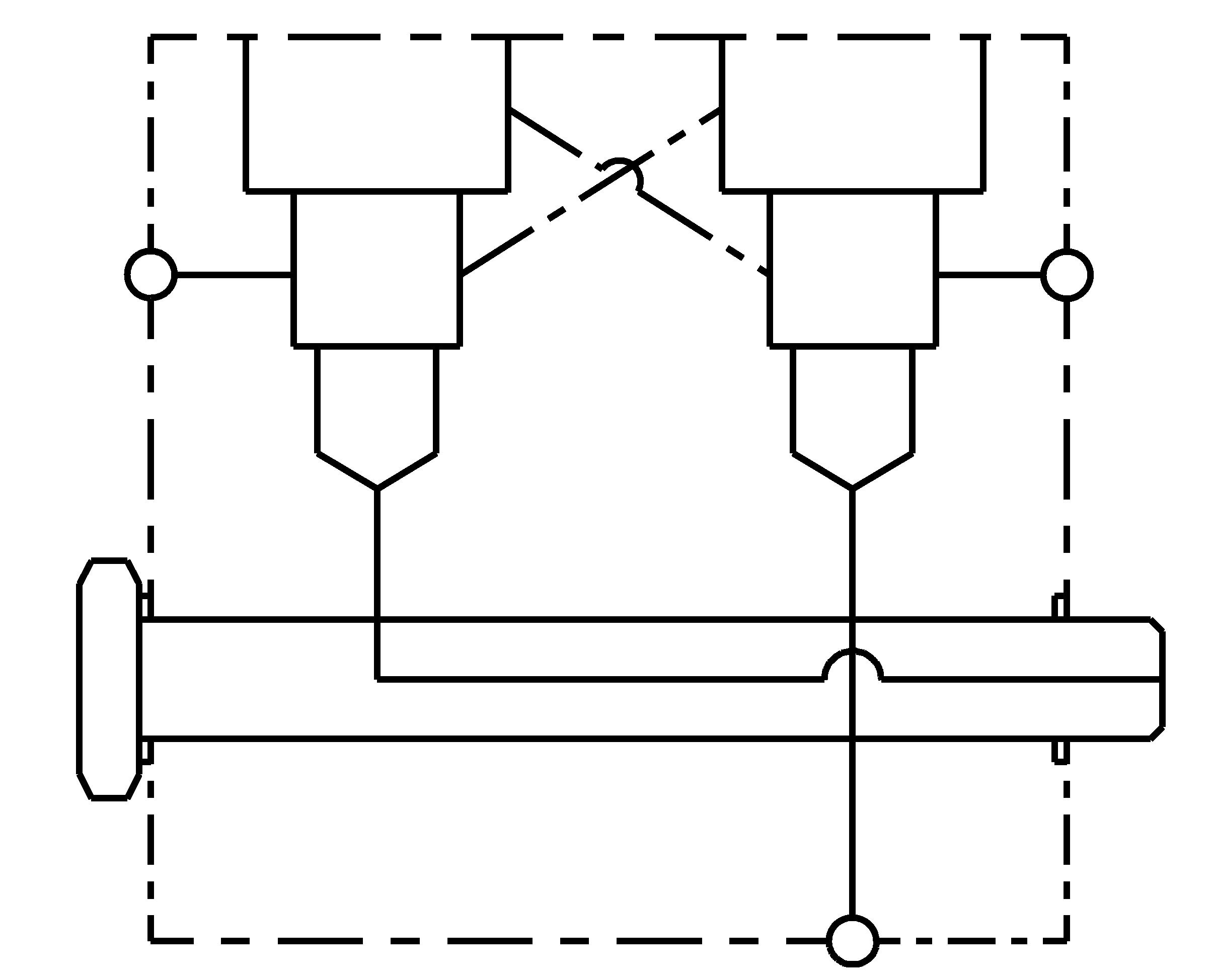

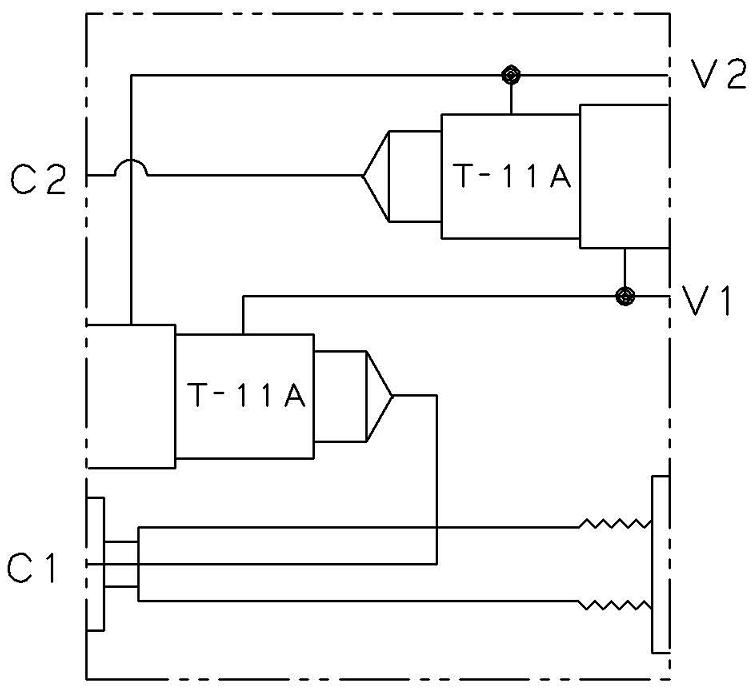

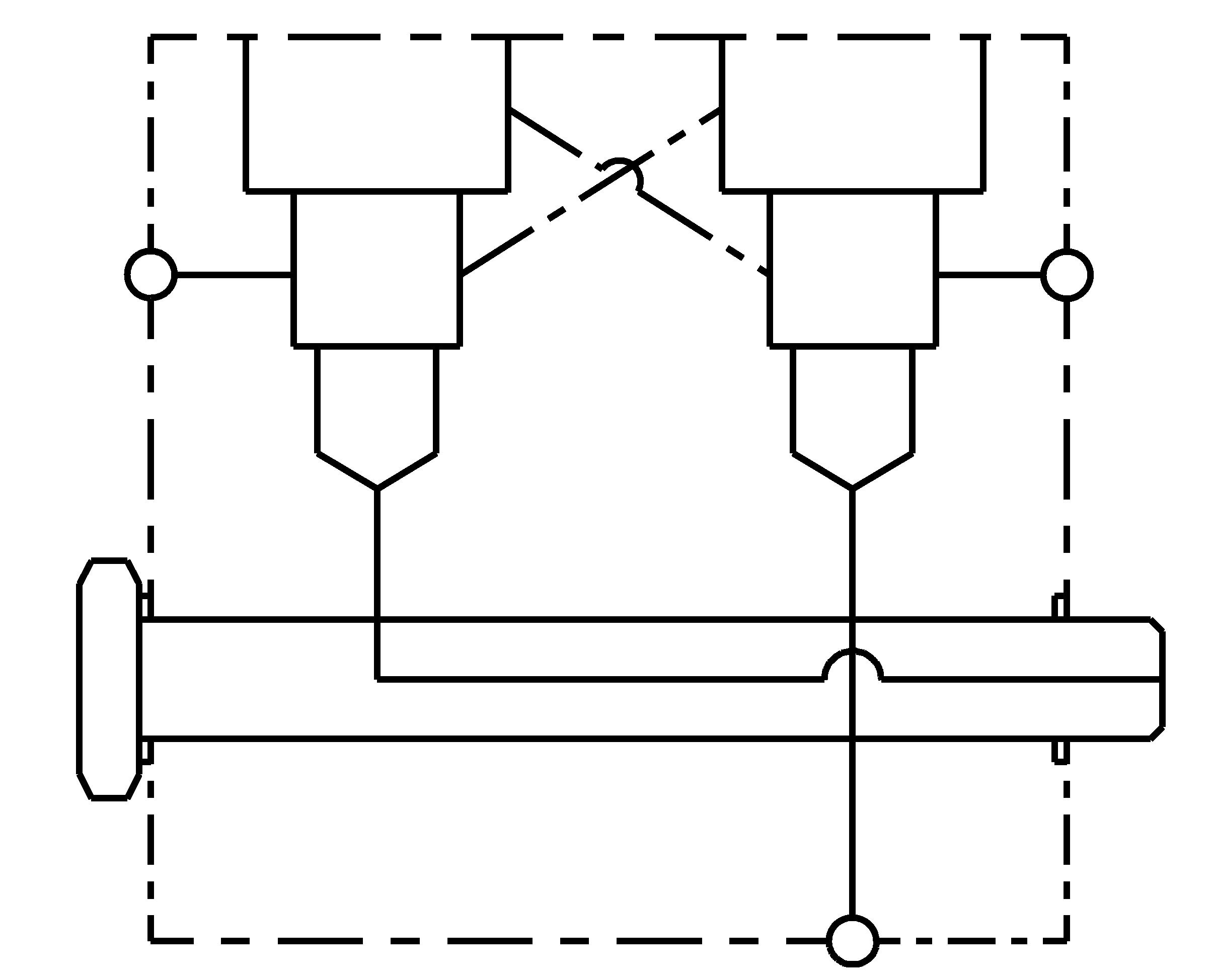

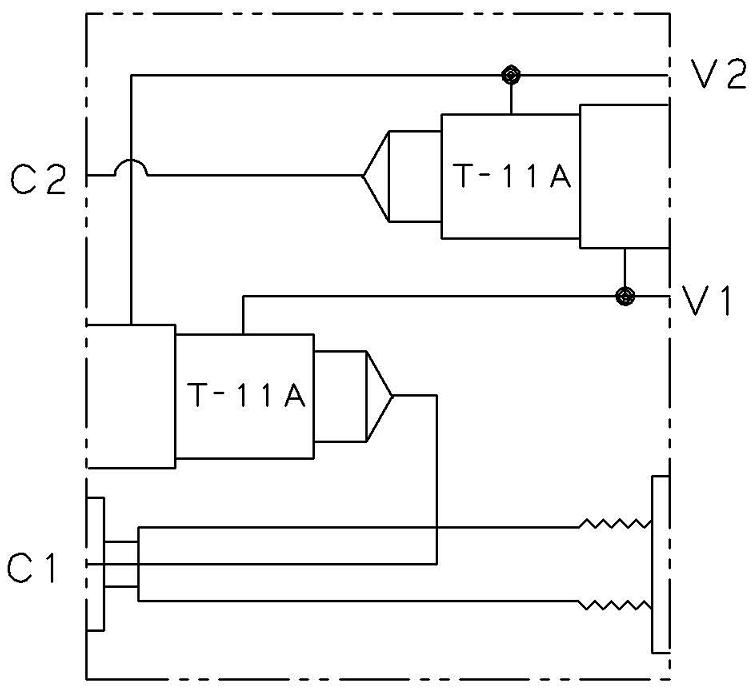

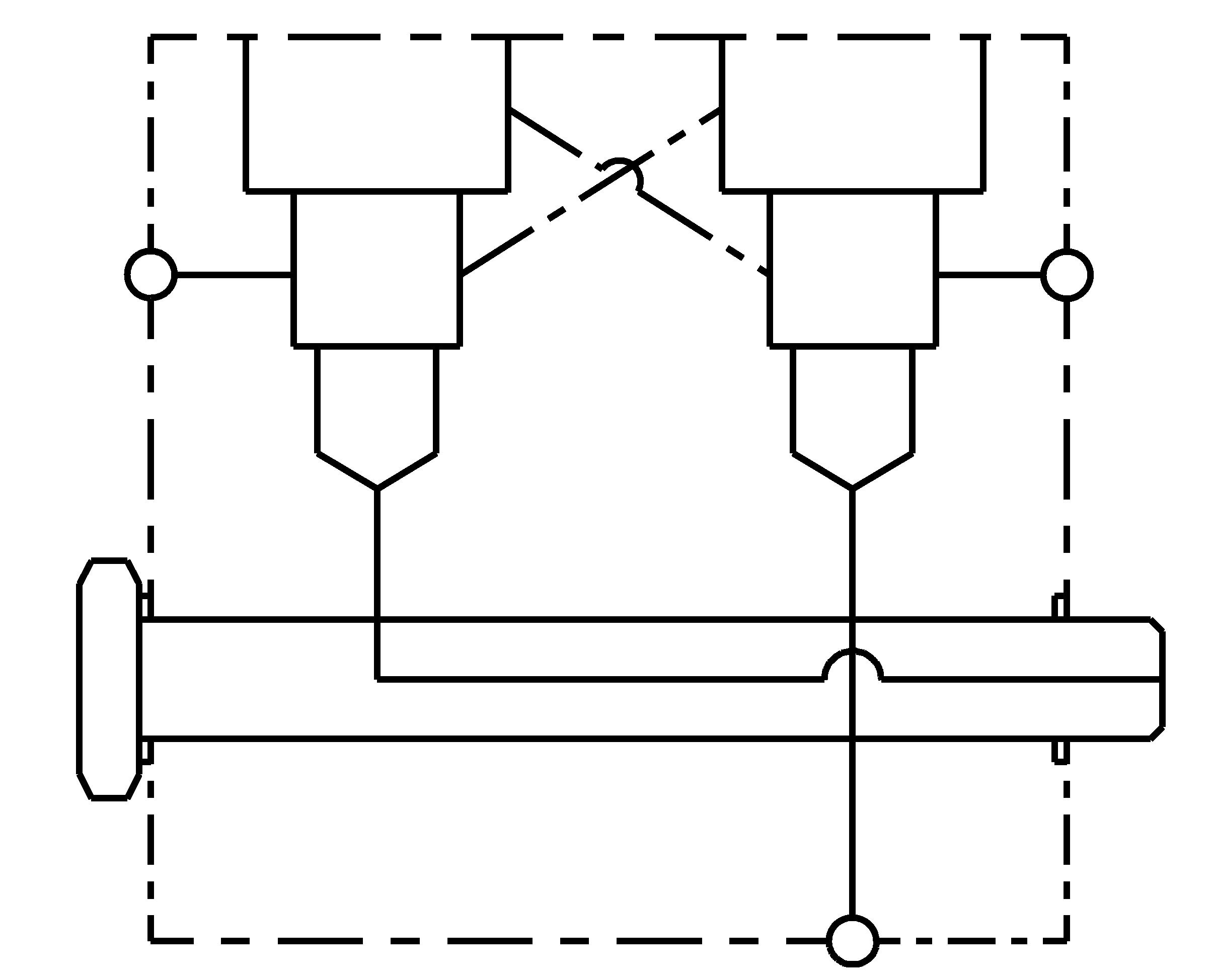

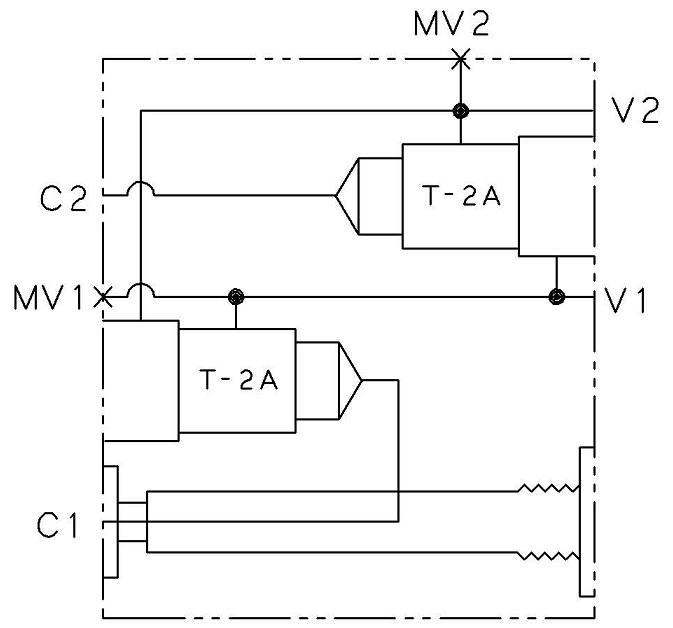

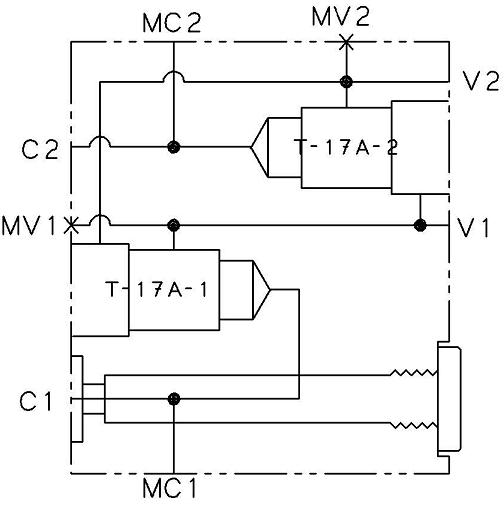

If you want to design with safety as a priority, banjo mount bodies are an excellent choice. By mounting the valve directly on the hydraulic cylinder, hoses between the valve and cylinder—often a weak point in the system—are eliminated. This significantly reduces the risk of hose failure that could bypass safety functions. At the same time, installation and fine-tuning are simplified since long hoses no longer affect valve performance. The solution is also highly flexible: multiple functions can be integrated into a single banjo mount body, saving space and improving system design. For optimal performance, Hydnet’s Choke Free banjo bolt is recommended, providing higher flow and lower pressure drop.

Banjo mounting offers a highly reliable way to integrate load-holding valves, pilot-operated check valves, and hose burst valves. Removing intermediate hoses prevents external disturbances and component failures—especially critical in safety-sensitive applications.

Banjo mount bodies are available both as standard units and customized versions. We offer the possibility to tailor banjo bodies according to function, space, and other requirements—without compromising safety or flow capacity. Contact one of our engineers for expert assistance!

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se