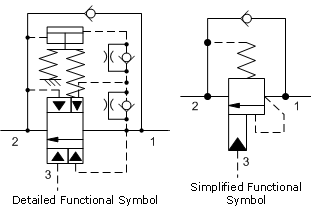

3 ports, pilot-to-open, standard pilot, steel seat

Sun Hydraulics offer a wide range of corrosion resistant load holding valves such as pilot operated check valves, counterbalance valves and balanced load holding valves. Stainless steel cartridge valves are the optimal choice for corrosion-prone environments, such as marine applications, where the risk of rust and material degradation is high. The valves are available either in stainless steel or in standard steel with a zinc-nickel surface treatment that provides effective corrosion protection. SUN Hydraulics stainless steel valves have been salt spray tested for a minimum of 1,000 hours in accordance with quality standards ASTM B117-03 and ISO 9227.

3 ports, pilot-to-open, standard pilot, steel seat

3 ports, pilot-to-open, sealed pilot, steel seat

3 ports, pilot-to-open, sealed pilot, steel seat, vent to air

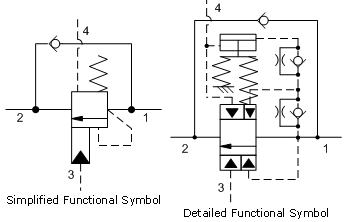

4 ports, pilot-to-open, sealed pilot, steel seat, vented

3 ports, non vented, restrictive

3 ports, non vented, ultra-restrictive

3 ports, non vented, fixed setting, standard

3 ports, non vented, fixed setting, semi-restrictive

3 ports, non vented, fixed setting, restrictive

3 ports, atmospherically referenced, standard

3 ports, atmospherically referenced, semi-restrictive

3 ports, non vented without pilot assist, standard

3 ports, non-vented, standard

3 ports, non-vented, restrictive

3 ports, load control valve, load reactive, non vented

3 ports, load control valve, load reactive, non vented

4 ports, load control valve, load reactive, vented

4 ports, load control valve, load reactive, vented

4 ports, load control valve, load reactive, vented

3 ports, load control valve, balanced cartridge, non vented

4 ports, load control valve, balanced cartridge, vented

3 ports, non-vented, self-adjusted

4 ports, vented, self-adjusted

Load holding valves are used in applications where it is necessary to prevent a load from moving when the directional valve is in the closed position. Most spool-type directional valves have some internal leakage, which means they cannot hold a load in a fixed position over an extended period. A load holding valve can also serve as a safety valve in the event of, for example, a hose rupture. In such cases, it should be mounted directly on the cylinder or other actuator. This is preferably done using a banjo manifold, which enables a compact and secure installation with minimal pressure losses and a reduced risk of hose failure.

Load holding valves are among the more complex type of hydraulic valves, making it especially important to select the correct model. Choosing the wrong valve can pose serious safety risks—such as the inability to hold a load securely—but can also result in inefficient system performance. Common problems caused by incorrect sizing include inadequate operating speed, system instability (shaking or jerking) or overheating. To ensure that your hydraulic system operates safely and efficiently, we recommend contacting one of our sales engineers. We’ll be happy to help you find the right solution tailored to your application.

Be aware that any back pressure in port 2 is added to the valve’s set opening pressure. This is common in systems that include a downstream restriction, such as a throttle or a proportional valve. If back pressure is an issue in your application, we recommend using an externally drained valve, specifically designed to handle such conditions.

Unlike many other hydraulic components, load holding valves should not be oversized. An oversized valve can cause system instability and reduced performance, particularly at low flow rates. To ensure stable operation, versions with lower flow capacity—but with the same cavity—are available.

At Hydnet, we work daily to design smart and compact hydraulic systems tailored to each customer’s unique needs. Our goal is to deliver solutions that not only ensure optimal performance but also contribute to a safe working environment—where the right components minimize the risk of downtime and personal injury. Don’t hesitate to contact us—we’re here to help you design a system that is both efficient and safe.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se