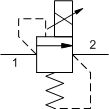

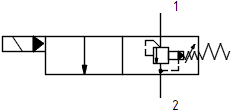

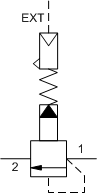

2 ports, electro-proportional relief valve – pilot capacity, high pressure setting with no command

Pressure relief valves are commonly used as safety valves to ensure that system pressure does not exceed a predetermined limit. The most common types are direct-acting and pilot-operated relief valves. Direct-acting pressure relief valves are typically used to protect hydraulic motors or cylinders from pressure spikes and are best installed close to the component they are protecting. Pilot-operated pressure relief valves are used to maintain a specific system pressure and to regulate pressure in various functions. These valves can be controlled in several ways, such as by pressure at the valve’s inlet or by an external pilot pressure. External pilot pressure can also be controlled electrically via electro-proportional control.

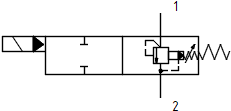

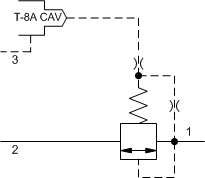

2 ports, electro-proportional relief valve – pilot capacity, high pressure setting with no command

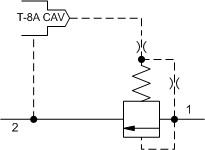

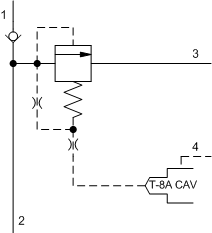

2 ports, pilot operated, balanced piston relief main stage with integral T-8A control cavity

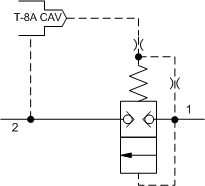

2 ports, pilot operated, balanced poppet relief main stage with integral T-8A control cavity

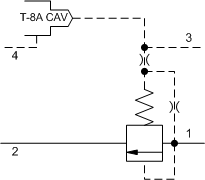

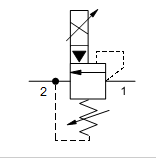

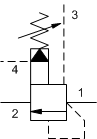

4 ports, relief valve main stage balanced piston

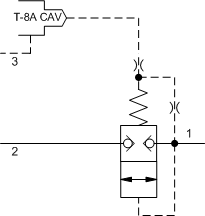

3 ports, pilot operated, balanced poppet sequence main stage with integral T-8A control cavity

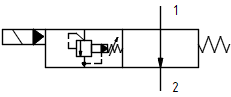

2-stage, FLeX series, solenoid-operated adjustable relief valve, normally vented. Coil options high power 5000 psi or explosion proof.

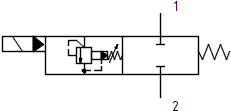

2-stage, FLeX series, solenoid-operated adjustable relief valve, normally blocked. Coil options high power 5000 psi or explosion proof.

2-stage, FLeX series, solenoid-operated adjustable relief valve, energize to block. Coil options high power 5000 psi or explosion proof.

2-stage, FLeX series, solenoid-operated adjustable relief valve, energize to vent. Coil options high power 5000 psi or explosion proof.

2 ports, non-adjustable direct-acting

2 ports, direct-acting, CE marked. Please note, RDFT is no longer available. For replacement, please contact one our sales engineers.

2 ports, fast-acting, pilot operated, balanced piston

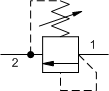

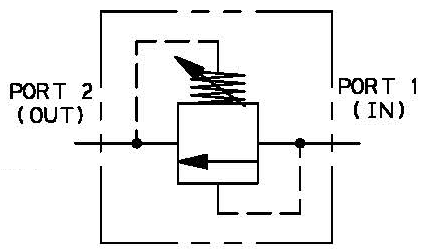

2 ports, pilot operated, balanced poppet

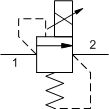

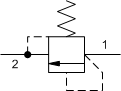

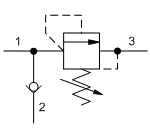

2 ports, electro-proportional relief valve – pilot capacity

2 ports, anti Shock, pilot operated, balanced poppet

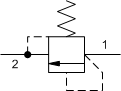

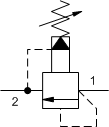

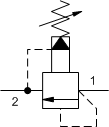

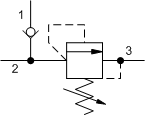

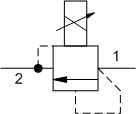

2 ports, direct acting, pilot capacity

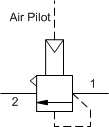

2 ports, air-controlled, pilot operated, balanced piston

2 ports, air-controlled, direct-acting, pilot capacity

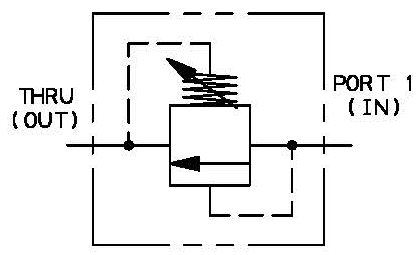

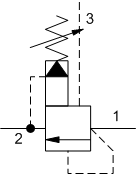

3 ports, ventable, pilot operated, balanced poppet

3 ports, anti Shock, ventable, pilot operated, balanced poppet

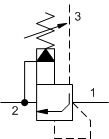

3 ports, dual, direct-acting relief valve, pilot capacity

4 ports, ventable, pilot operated, balanced piston – before check

4 ports, ventable, pilot operated, balanced piston relief main stage with integral T-8A control cavity – before check

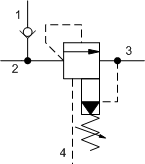

4 ports, ventable, pilot operated, balanced piston, drain to port 4

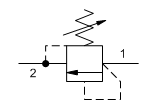

2 ports, electro-proportional relief valve – pilot capacity

2 ports, bi-directional direct-acting relief valve

3 ports, pilot operated, balanced piston sequence main stage with integral T-8A control cavity

All hydraulic systems require a primary system pressure limiter to ensure a safe maximum system pressure. In addition, it is often beneficial to install local pressure relief valves to protect specific parts of the system from pressure spikes and overload. Sun Hydraulics offers a wide range of pressure relief valves in various designs and configurations – tailored for different applications, flows and pressure levels.

A direct-acting pressure relief valve is well-suited for protecting consumers, such as hydraulic motors or cylinders, from pressure spikes. It is ideally placed close to the component it is designed to protect, ensuring the fastest possible response. The valve has a response time of approximately 2 milliseconds, making it faster than a pilot-operated pressure relief valve, which has a response time of around 10 milliseconds. Due to the large spring force relative to the flow, direct-acting valves can be more difficult to adjust in a pressurized system. This distinguishes them from pilot-operated pressure relief valves, which are easier to fine-tune even under pressure.

Pilot-operated pressure relief valves are well-suited for maintaining stable system pressure and regulating pressure in specific functions. They offer great flexibility and can be controlled in several ways – either by the internal pressure from the valve inlet or through an external pilot pressure. When external pilot pressure is used, it can be controlled electrically, i.e., with electro-proportional control. This enables switching between two or more pressure levels in the system, depending on the requirements. This solution is also used to relieve the pressure limiter in systems with a fixed pump. In such cases, the flow does not need to pass through the pressure limiter but can be directed straight to the tank, saving energy and preventing heat buildup.

Like all other cartridge valves from Sun Hydraulics, pressure relief valves are thoroughly tested before leaving the factory to ensure the highest quality and performance. Both direct-acting and pilot-operated pressure relief valves are designed to handle flows up to 800 l/min and can be adjusted for pressure levels up to 350 bar or 420 bar. Additionally, they are designed to be resistant to dirt and other contaminants, ensuring long-lasting and reliable performance even in demanding environments.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se