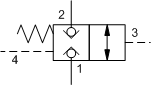

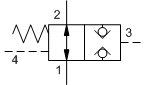

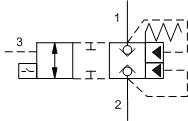

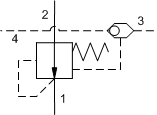

Normally closed, direct operated, balanced poppet

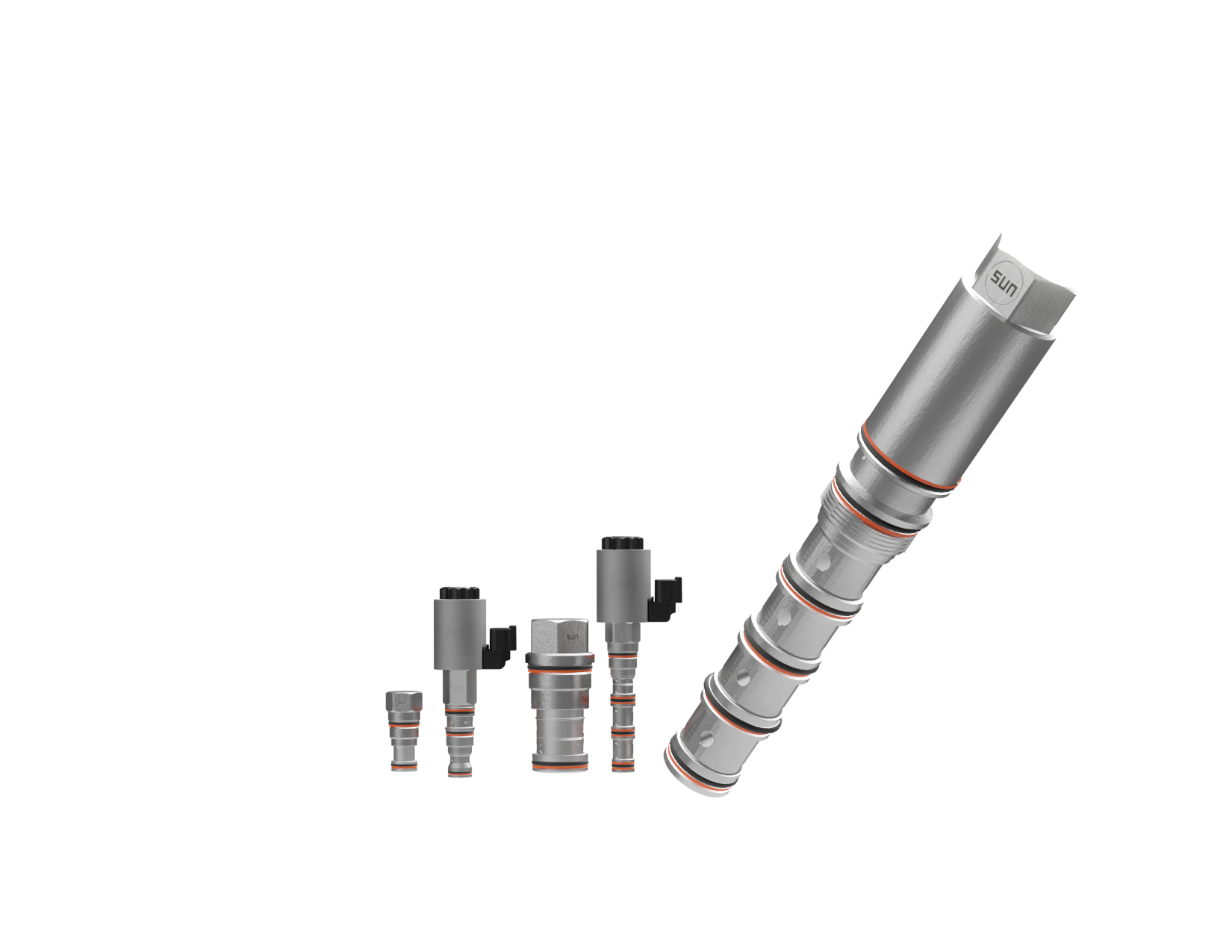

A logic element (logic valve) is a type of directional valve used to control flow or pressure based on certain logical conditions – “if this happens, then do that.” It functions similarly to a logic gate, where a control signal determines how the logic element will respond. Logic elements are often used to build hydraulic control logic without electronics, making the systems robust and reliable, even in demanding environments. These valves can be used in a wide range of hydraulic systems and when combined with other valves, can create functions for directional, flow and pressure control. They are available in both balanced and unbalanced versions, depending on the application requirements.

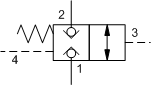

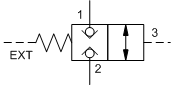

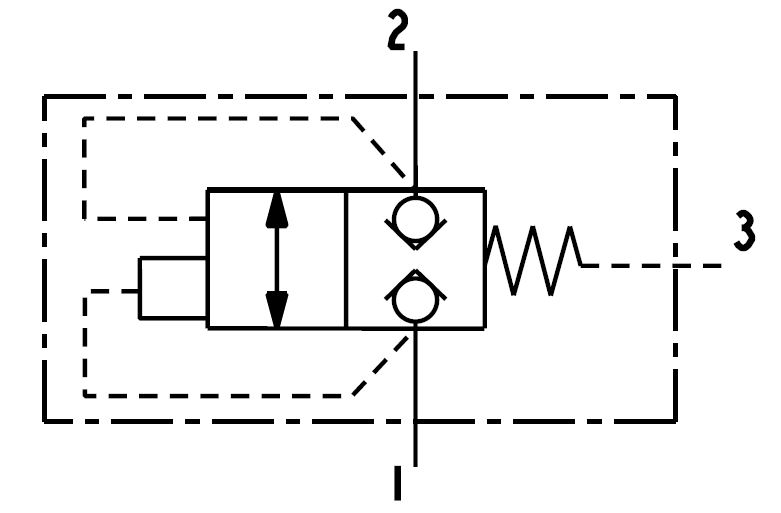

Normally closed, direct operated, balanced poppet

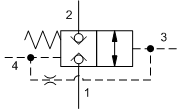

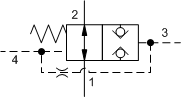

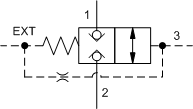

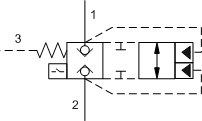

Normally closed, vent to operate, balanced poppet

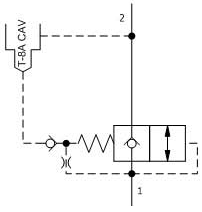

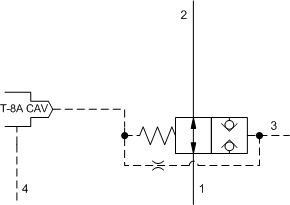

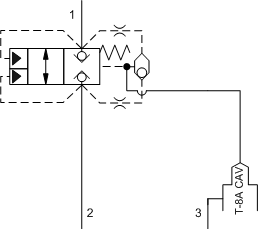

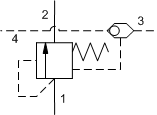

Poppet, control 1 to 2 with integral T-8A pilot control, 2-way

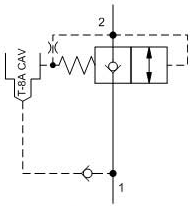

Poppet, control 2 to 1 with integral pilot control cavity, 2-way

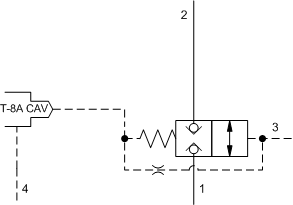

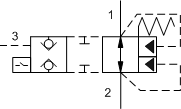

Normally closed, vent to operate, with integral pilot control cavity, balanced poppet

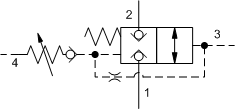

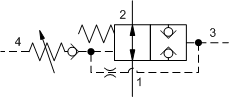

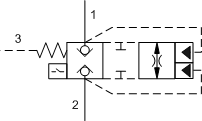

Normally closed, pressure adjustable, balanced poppet

Normally open, directly operated, balanced poppet

Normally open, vent to operate, balanced poppet

Normally open, vent to operate, with integral pilot control cavity, balanced poppet

Normally open, pressure adjustable, balanced poppet

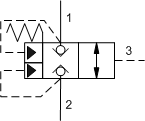

3 ports, normally closed, direct operated, balanced poppet

3 ports, normally closed, vent to operate, balanced poppet

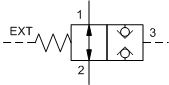

3 ports, normally open, direct operated, balanced poppet

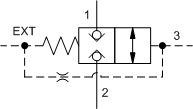

3 ports, normally open, vent to operate, balanced poppet

Pilot-to-close, spring biased closed with metering notches, unbalanced poppet

Vent-to-open, spring biased closed, with pilot source from port 1 or 2 and integral pilot control cavity, unbalanced poppet

Pilot-to-close, spring biased open with position indicating switch, unbalanced poppet

Pilot-to-open, spring biased closed, unbalanced poppet

Pilot-to-open, spring biased closed with position indicating switch, unbalanced poppet

Pilot-to-close, spring biased closed with position indicating switch, unbalanced poppet

Pilot-to-close, spring biased closed with metering notches and position indicating switch, unbalanced poppet

Bi-directional, modulating

Bypass/Restrictive, modulating

Balanced logic elements are not affected by pressure variations in the system but respond solely to the control signal/control pressure. They are used, for example, when it is necessary to open or close the valve regardless of the load. A balanced logic element is used in applications where stable operation and precise control must be ensured despite changes in system pressure, such as in hydraulic presses and lifting cranes.

Unbalanced logic elements are influenced by the load and system pressure, not only by a control signal. The valve opens or closes depending on both the control pressure and the system pressure, which makes it simpler and more cost-effective, but also less precise than a balanced logic element. However, the advantage of an unbalanced logic element is that no external pilot source is needed; the pressure from the load itself can be used to open the valve.

A monitored logic element provides feedback in the form of an electrical signal indicating whether the valve is in the open or closed position. These valves are commonly used in applications where personal safety is critical or where compliance with machine and safety standards is required. They are frequently found in industries such as steel mills, paper mills, power plants, and other facilities with safety or work cells, where reliable feedback is essential. Monitored logic elements can, for example, confirm that a function is fully switched off during maintenance or be used as emergency shutdowns in safety systems.

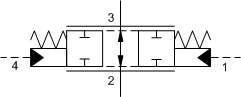

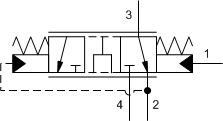

Logic elements can be controlled by multiple pressure signals, allowing for the construction of more complex systems based on logical principles, similar to electrical logic gates. Logic elements are used, among other things, to assemble directional valve functions for large flows.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se