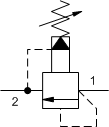

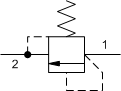

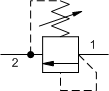

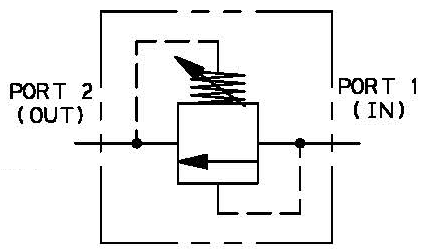

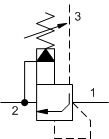

2 ports, pilot operated, balanced piston

Sun Hydraulics offers a wide range of corrosion resistant pressure control valves, including pressure relief valves, pressure reducing valves, reducing/relieving valves, and sequence valves. Stainless steel cartridge valves are the optimal choice for corrosion-prone environments, such as marine applications, where the risk of rust and material degradation is high. The valves are available either in stainless steel or in standard steel with a zinc-nickel surface treatment that provides effective corrosion protection. SUN Hydraulics stainless steel valves have been salt spray tested for a minimum of 1,000 hours in accordance with quality standards ASTM B117-03 and ISO 9227.

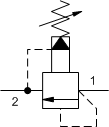

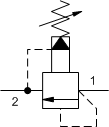

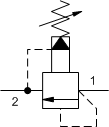

2 ports, pilot operated, balanced piston

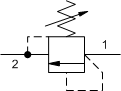

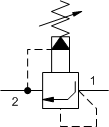

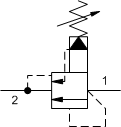

2 ports, direct-acting

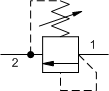

2 ports, low-pressure-range, direct-acting

2 ports, direct-acting, CE marked. Please note, RDFT is no longer available. For replacement, please contact one our sales engineers.

2 ports, fast-acting, pilot operated, balanced piston

2 ports, pilot operated, balanced poppet

2 ports, anti Shock, pilot operated, balanced poppet

2 ports, direct acting, pilot capacity

2 ports, kick-down, pilot operated, balanced piston

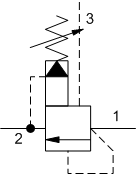

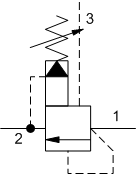

3 ports, ventable, pilot operated, balanced piston

3 ports, ventable, pilot operated, balanced poppet

3 ports, anti Shock, ventable, pilot operated, balanced poppet

3 ports, dual, direct-acting relief valve, pilot capacity

3 ports, direct-acting – after check

3 ports, direct-acting – before check

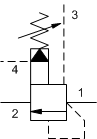

4 ports, ventable, pilot operated, balanced piston, drain to port 4

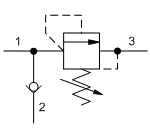

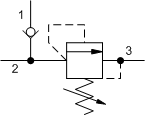

3 ports, pilot operated reducer 2-way

3 ports, pilot operated reducer 2-way drilled orifice direct in main spool

3 ports, direct acting reducer 2-way

3 ports, reducer main stage 2-way

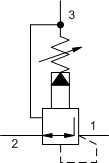

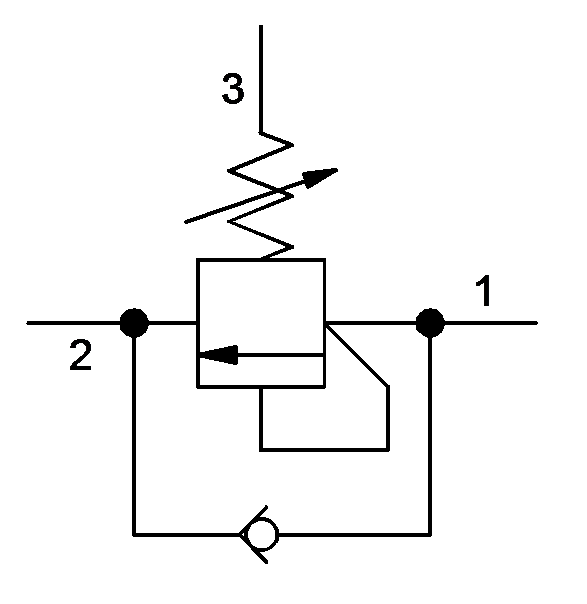

3 ports, pilot operated reducing/relieving 3-way

3 ports, pilot operated reducing/relieving, air controlled 3-way

3 ports, direct acting reducing/relieving 3-way

3 ports, direct acting reducing/relieving – open transition 3-way

4 ports, pilot operated reducing/relieving, externally drained 3-way

4 ports, pilot operated reducing/relieving, ventable 3-way

4 ports, pilot operated reducing/relieving, externally drained 3-way orifice direct drilled in piston

4 ports, direct acting reducing/relieving, main stage 3-way real 0-pressure, high accuracy

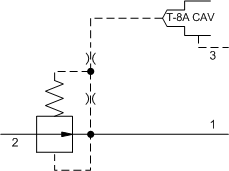

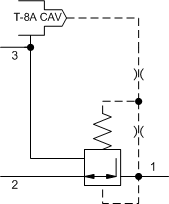

3 ports, reducing/relieving main stage with integral T-8A pilot control 3-way

2 ports, atmospherically referenced, direct acting without reverse flow check

3 ports, pilot operated, balanced piston

3 ports, pilot operated, balanced poppet

3 ports, direct acting with reverse flow check

3 ports, direct acting without reverse flow check

3 ports, kick-down

Pressure control valves often play a critical role in a hydraulic system by regulating and limiting pressure across various functions to ensure stable and safe operation. Hydnet offers a comprehensive range of pressure control valves from Sun Hydraulics, available in a wide variety of designs and functions to meet the diverse demands of both industrial and mobile applications. A key advantage of many of these valves is that they share the same cavity, providing design flexibility and simplifying installation, maintenance, and future system modifications.

Pressure relief valves are commonly used as safety valves to ensure that system pressure does not exceed a predetermined limit. The most common types are direct-acting and pilot-operated relief valves. Direct-acting pressure relief valves are typically used to protect hydraulic motors or cylinders from pressure spikes and are best installed close to the component they are protecting. Pilot-operated pressure relief valves are used to maintain a specific system pressure and to regulate pressure in various functions. These valves can be controlled in several ways, such as by pressure at the valve’s inlet or by an external pilot pressure. External pilot pressure can also be controlled electrically via electro-proportional control.

Pressure reducing valves are used when a specific part of a hydraulic system requires a lower pressure than the rest of the system. Direct-acting pressure reducing valves respond quickly to changes in pressure and exhibit significantly lower leakage compared to pilot-operated valves, making them well-suited for accumulator circuits. Pilot-operated pressure reducing valves, on the other hand, offer versatile control options and can be actuated by the pressure at the valve’s outlet or by external pilot pressure. As with relief valves, the external pilot pressure can be electrically controlled using electro-proportional technology.

A sequence valve is a control valve used in hydraulic systems to determine the order in which various functions are activated, based on pressure levels. It ensures that one operation is initiated only after a specific pressure is reached in another part of the system. The sequence valve remains closed under normal conditions and opens only when the pressure reaches a preset value. A common application is with two hydraulic cylinders, where “cylinder two” starts moving only after “cylinder one” is fully extended. Sequence valves are typically used in systems such as lifting equipment, presses, hydraulic grippers, and sequential hatch control.

Hydnet

EA Rosengrens gata 29

421 32 Västra Frölunda

+46 31 - 499 490

info@hydnet.se